Fermenting technology for improving expression amount of fusion protein of recombinant human brain natriuretic peptide

A technology of human brain natriuretic peptide and fermentation process, which is applied in the field of fermentation process to improve the expression of recombinant human brain natriuretic peptide fusion protein, which can solve the problem that industrial production cannot be realized, it has no commercial development value, and the expression of fusion protein is affected etc. to achieve good commercial development value, low production cost, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

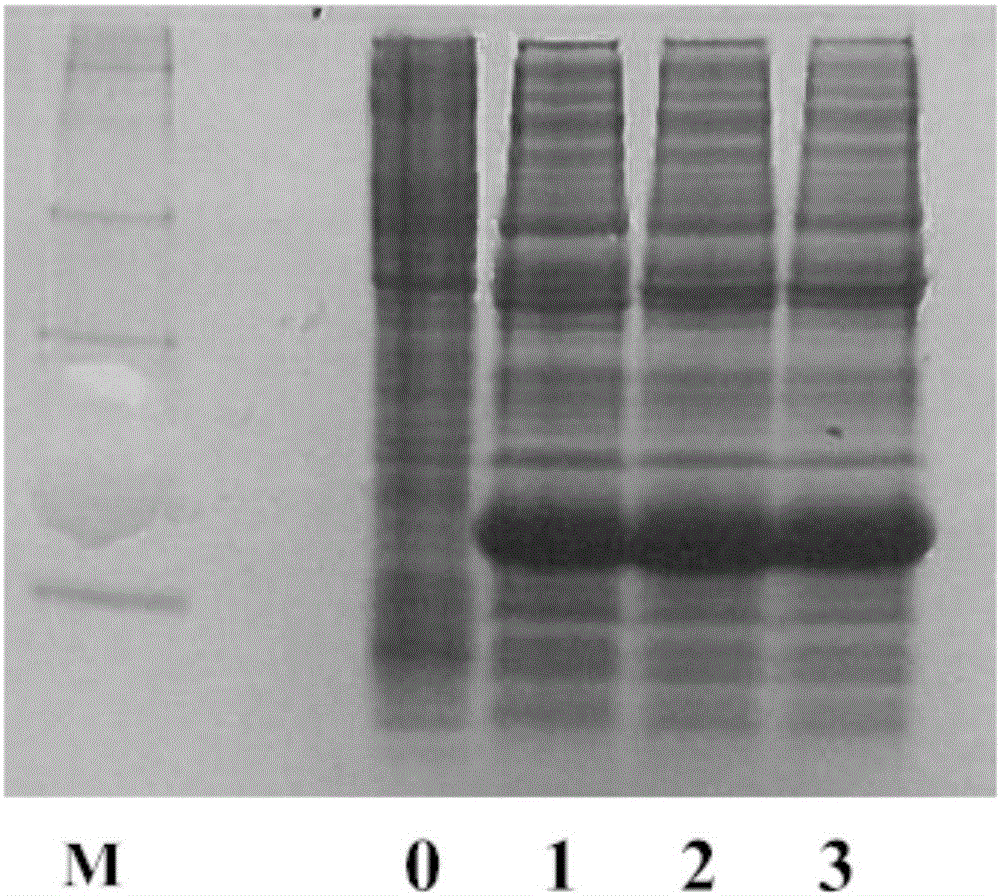

Image

Examples

Embodiment 1

[0031] In the fermentor, add 18.5L of BHD medium and 74mL of glycerol, and ampicillin to its final concentration of 100mg / L, inoculate 400mL of recombinant human brain natriuretic peptide (rhBNP) genetically engineered bacteria, adjust the ventilation rate so that the Dissolved oxygen (ie D.O. value) is 50%, add hydrochloric acid or sodium hydroxide to adjust the pH value to 7.0, and the culture temperature is 37°C; when OD 600 (referring to the absorbance value at 600nm wavelength place) when being 12, adding IPTG (isopropyl thiogalactopyranoside) to its final concentration is 0.5mmol / L (mmol / L refers to millimole / liter) induction, and Add 200mL / h feed solution A to the fermenter, stop the fermentation culture after 4h, and harvest the bacteria;

[0032] in,

[0033] The formula of the BHD medium is as follows: each liter of BHD medium contains 5 g of tryptone (Tryptone), 10 g of yeast powder (Yeast Extract), potassium dihydrogen phosphate (KH 2 PO 4 ) 2.31g, dipotassium h...

Embodiment 2

[0039] In the fermentor, add 20L of BHD medium, 68mL of glycerol, and ampicillin to a final concentration of 100mg / L, inoculate 400mL of recombinant human brain natriuretic peptide (rhBNP) genetically engineered bacteria, adjust the aeration rate to make the solution in the fermentation broth Oxygen content (being D.O. value) is 30%, adds hydrochloric acid or sodium hydroxide to adjust pH value to be 7.0, and culture temperature is 37 ℃; When OD 600 At 12 o'clock, add IPTG (isopropylthiogalactopyranoside) to its final concentration of 1.0mmol / L induction, and add 200mL / h feed solution A to the fermenter, stop fermentation after 4h, and harvest bacteria;

[0040] in,

[0041]The formula of the BHD medium is as follows: each liter of BHD medium contains 5 g of tryptone (Tryptone), 10 g of yeast powder (Yeast Extract), potassium dihydrogen phosphate (KH 2 PO 4 ) 2.31g, dipotassium hydrogen phosphate (K 2 HPO 4 ) 12.54g, magnesium sulfate (MgSO 4 ) 0.5g, sodium chloride (NaC...

Embodiment 3

[0045] In the fermentor, add 18.5L of BHD medium and 74mL of glycerol, and ampicillin to its final concentration of 100mg / L, inoculate 400mL of recombinant human brain natriuretic peptide (rhBNP) genetically engineered bacteria, adjust the ventilation rate so that the Dissolved oxygen (ie D.O. value) is 50%, add hydrochloric acid or sodium hydroxide to adjust the pH value to 7.0, and the culture temperature is 37°C; when OD 600 At 12 o'clock, add IPTG (isopropylthiogalactopyranoside) to its final concentration of 0.8mmol / L induction, and feed 200mL / h feed solution A in the fermentor, stop fermentation after 4h, harvest bacteria;

[0046] in,

[0047] The formula of the BHD medium is as follows: each liter of BHD medium contains 5 g of tryptone (Tryptone), 10 g of yeast powder (Yeast Extract), potassium dihydrogen phosphate (KH 2 PO 4 ) 2.31g, dipotassium hydrogen phosphate (K 2 HPO 4 ) 12.54g, magnesium sulfate (MgSO 4 ) 0.5g, sodium chloride (NaCl) 0.6g, vitamins (panto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com