Ultraviolet LED packaging device

A technology of LED packaging and LED chips, which is applied in the field of ultraviolet LED, can solve the problems that cannot meet the high performance of ultraviolet LED, long service life, low light extraction rate and heat dissipation capacity, device reliability and shortened life, etc., to achieve the elimination of light loss, reduced Fresnel loss, reduced absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments thereof, but should not be construed as limiting the invention.

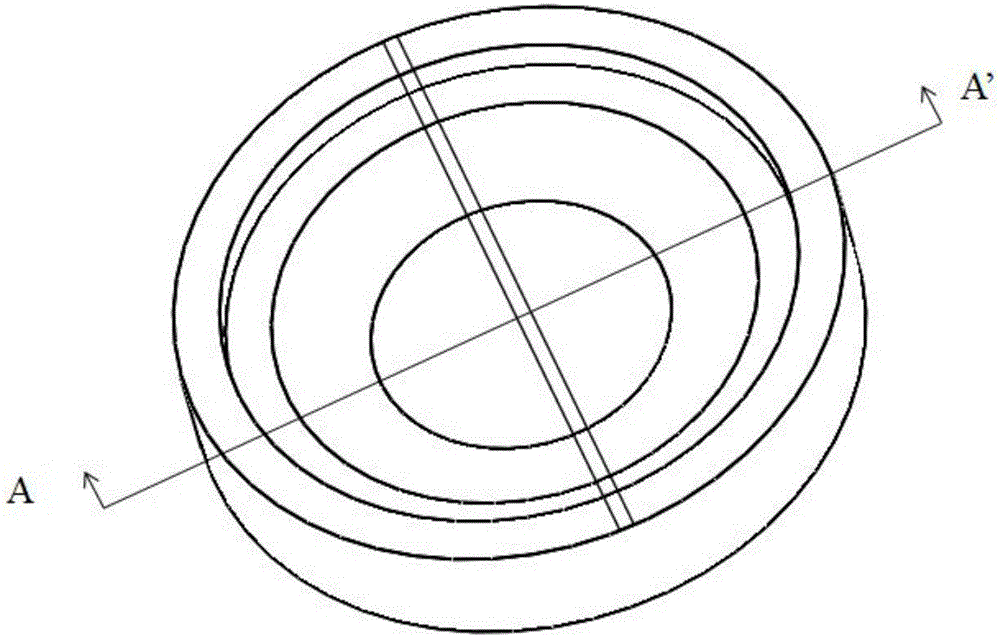

[0026] figure 1 It is a schematic diagram of the three-dimensional structure of the alumina ceramic substrate in the ultraviolet LED packaging device of the present invention. From the bottom surface of the groove of the alumina ceramic substrate 111 to the top layer of the substrate, there is a narrow strip symmetrical to the center line, which belongs to the area without copper plating as the insulating area. In this way, the insulating property of the alumina ceramic 111 itself divides the conductive copper plating layer 131 into two insulating parts.

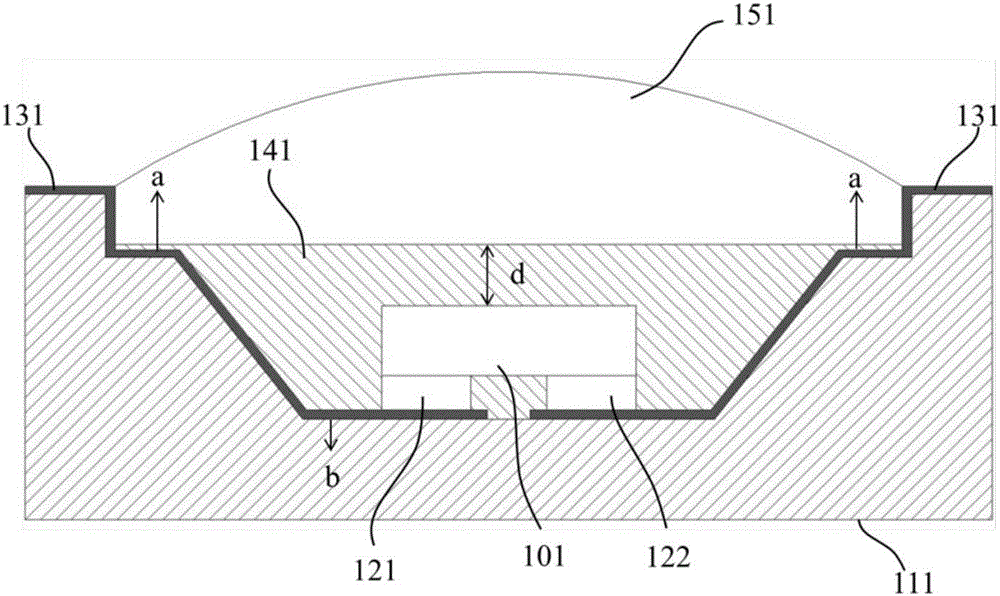

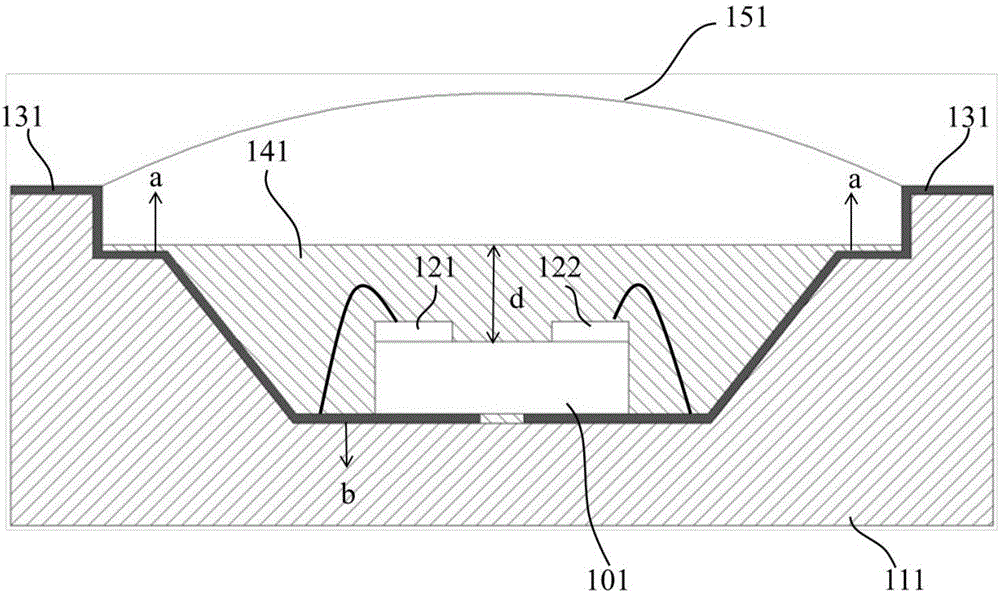

[0027] Figure 2-Figure 5 Respectively, the structure I, II, III and IV of the ultraviolet LED packaging device of the present invention are figure 1 Schematic diagram of the longitudinal section structure along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap