Method for improving performance of COFs (Covalent Organic Frameworks) material used as electrode active material

An electrode active material and performance technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor rate performance and low capacity utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

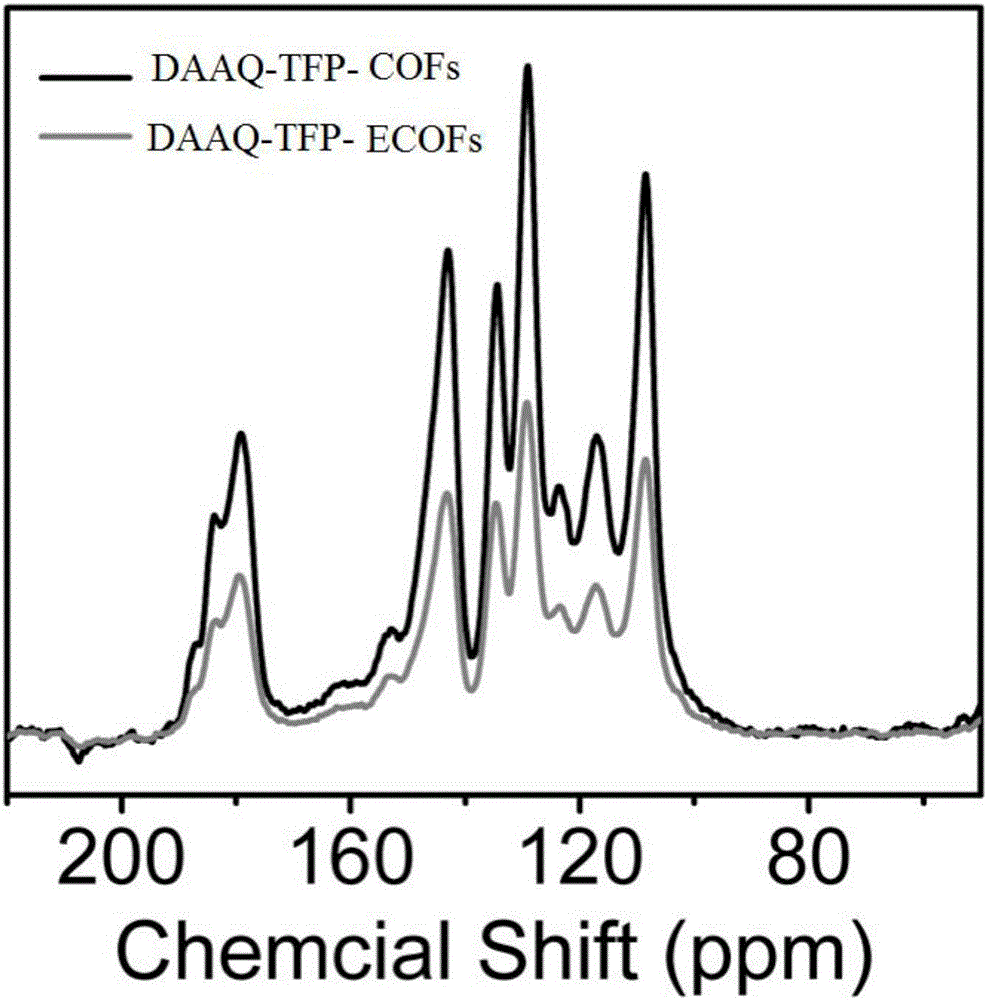

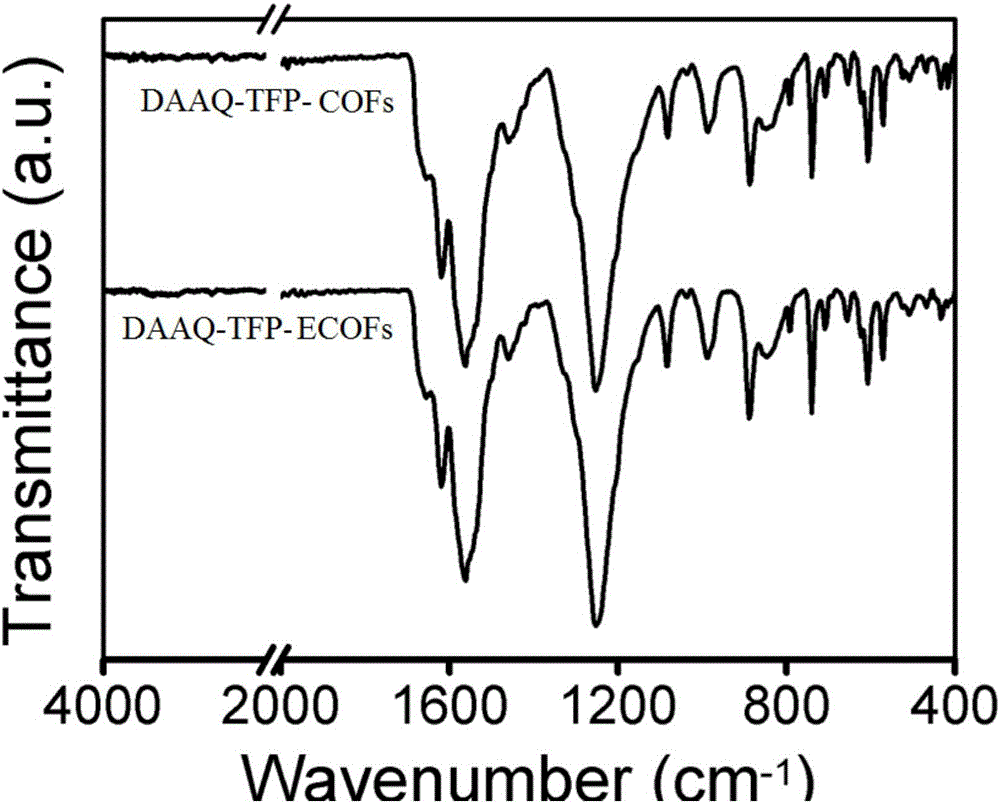

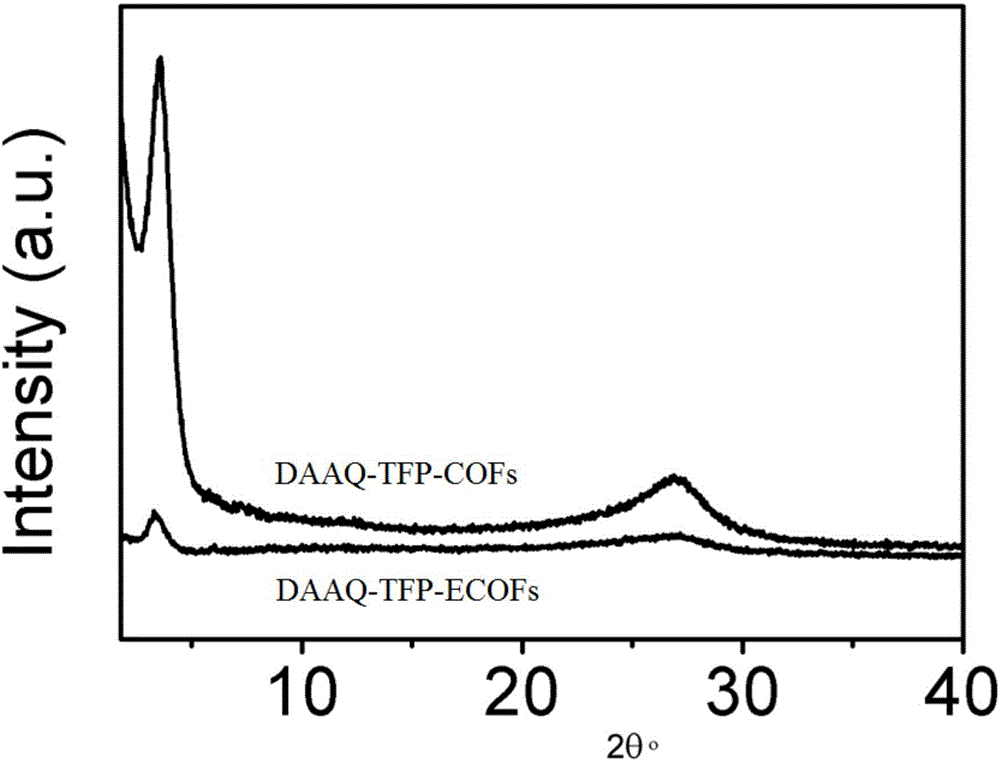

[0064] A method for improving the performance of COFs material as an electrode active material, the steps of the method are as follows:

[0065] (1) Add 34mg of DAAQ (0.142mmol), 20mg of TFP (0.95mmol) and mesitylene and N,N-dimethylacetamide with a volume ratio of 1:3 mixed solvent 2mL into a 10mL ampoule In the process, oxygen was removed by liquid nitrogen freezing and thawing pump circulation method, and the mouth of the ampoule bottle was calcined, melted, sealed and sealed with a flame gun, and placed in an oven at 120°C for 3 days. After cooling to room temperature, the obtained material was centrifuged to obtain a solid. The solid was washed with acetone after DMF, and dried under vacuum at 120° C. to obtain a deep red powdery material, which was a COFs material composed of DAAQ and TFP (hereinafter referred to as DAAQ-TFP-COFs material), with a yield of 73%.

[0066] (2) Put 150 mg of DAAQ-TFP-COFs material into a ball milling jar with a volume of 5 mL, add 4 steel ba...

Embodiment 2

[0089] (1) Mix 30mg of 2,5-diamino-1,4-dihydroxybenzene (DABH) (0.142mmol), 20mg of TFP (0.95mmol) with mesitylene and N,N-dimethylacetamide Add 1.2mL of mixed solvent with a volume ratio of 1:1 into a 10mL ampoule bottle, deoxygenate through the liquid nitrogen freezing and thawing pump circulation method, use a flame gun to calcinate, melt, seal and seal the ampoule bottle mouth, and place it in an oven at 100°C After reaction 3d, after cooling to room temperature, the obtained material was centrifuged to obtain a solid, which was first washed with DMF and then tetrahydrofuran, and dried in vacuum at 120°C to obtain a black powder material, which was a COFs material composed of DABH and TFP (hereinafter Referred to as DABH-TFP-COFs material), the yield was 87%.

[0090] In order to oxidize DABH-TFP-COFs into DABQ-TFP-COFs with redox active sites, 50 mg of DABH-TFP-COFs were dissolved in 5 mL of triethylamine, and then the suspension was air- Stir in the atmosphere for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com