Production device and production method of titanium welded pipe for electric heater

A technology for electric heaters and production equipment, applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficulty in pipe insertion, long manufacturing cycle, and desoldering, and achieve simple overall structure, ensure product quality, The effect of controlling production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

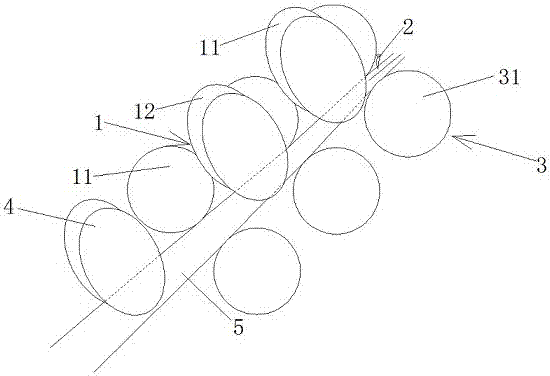

Embodiment 1

[0051] Raw material TA1 titanium belt, width 29.1, wall thickness 0.5mm, cold-formed by using a tape-winding mechanism with φ9.5 horizontal forming rollers and vertical forming rollers, to prepare straight seam titanium with φ9.5*0.5mm specification welded pipe. After the narrow titanium strip is formed by continuous cold pressing, arc welding is carried out. The welding process parameters used are: welding speed 0.5~1m / min, welding current 110~125A, welding voltage 8.8~9.4V, argon gas flow rate 10 ~25 l / min, the opening of the welding squeeze roller is 1.7mm, and the inclination angle between the welding torch and the workpiece is 40 degrees, so that the weld seam is fully filled and the transition is smooth and smooth. After welding, the eddy current non-destructive flaw detection device is used to detect the quality of the weld seam, and alarms are issued for defects, and alarms are issued at the beginning of the period. After welding, the coffin is subjected to sizing str...

Embodiment 2

[0054] Raw material TA1 titanium strip with a width of 38.9mm and a wall thickness of 0.65mm is used for cold-bending forming with a tape-reel mechanism with a horizontal forming roller and a vertical forming roller with a specification of φ12.7 to prepare straight seam titanium with a specification of φ12.7*0.65mm welded pipe. After the narrow titanium strip is formed by continuous cold pressing, arc welding is carried out. The welding process parameters used are: welding speed 0.5~1m / min, welding current 120~135A, welding voltage 8.8~9.4V, argon gas flow rate 10 ~25 l / min, the opening of the welding squeeze roller is 2.0mm, and the inclination angle between the welding torch and the workpiece is 45 degrees, so that the weld seam is fully filled and the transition is smooth and smooth. After welding, the eddy current non-destructive flaw detection device is used to detect the quality of the weld seam, and alarms are issued for defects, and alarms are issued at the beginning o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com