Method for using fly ash to prepare silicon compound fertilizer

A technology of fly ash and compound fertilizer, applied in urea compound fertilizer, nitrogen fertilizer, potash fertilizer and other directions, can solve problems such as insufficient application of fertilizer elements, and achieve the effects of increasing crop yield, easy absorption, and improving the quality of agricultural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

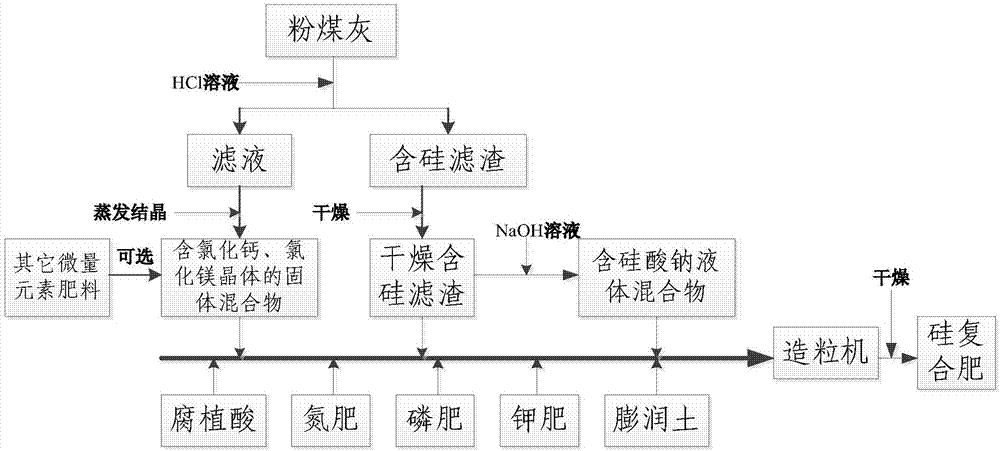

Image

Examples

Embodiment 1

[0029] The power plant fly ash is pulverized to 200 mesh with a pulverizer, and the pulverized fly ash is fully reacted with dilute hydrochloric acid with a concentration of 20% at a solid-liquid ratio of 1:3 (g / ml), and then filtered to obtain a mixture containing Silicon filter residue, and this silicon-containing filter residue is dried for use. At the same time, the obtained filtrate was evaporated and crystallized at 120° C. to obtain a solid mixture containing calcium chloride and magnesium chloride crystals for subsequent use. The standby silicon-containing filter residue is reacted with a sodium hydroxide solution with a concentration of 25% at a ratio of 1:1.5 (g / ml) at 80° C. to obtain a sodium silicate-containing liquid mixture.

[0030] Take 50 kilograms of weathered coal, 300 kilograms of urea, 350 kilograms of monoammonium phosphate, 250 kilograms of potassium chloride, 5 kilograms of bentonite, 10 kilograms of trace element fertilizers (10 kilograms of solid mix...

Embodiment 2

[0032] The power plant fly ash is ground to 180 mesh with a pulverizer, and the pulverized fly ash is fully reacted with dilute hydrochloric acid with a concentration of 15% at a solid-liquid ratio of 1:3.5 (g / ml), and then filtered to obtain a mixture containing Silicon filter residue, and this silicon-containing filter residue is dried for use. At the same time, the obtained filtrate was evaporated and crystallized at 130°C to obtain a solid mixture containing calcium chloride and magnesium chloride crystals for subsequent use. The standby silicon-containing filter residue and the sodium hydroxide solution with a concentration of 20% are reacted at 80° C. at a ratio of 1:1.2 (g / ml) to obtain a sodium silicate-containing liquid mixture.

[0033] Get 60 kilograms of peat, 350 kilograms of urea, 300 kilograms of calcium magnesium phosphate fertilizer, 200 kilograms of potassium sulfate, 10 kilograms of bentonite, 10 kilograms of trace element fertilizers (5 kilograms of solid m...

Embodiment 3

[0035] The power plant fly ash is ground to 150 mesh with a pulverizer, and the pulverized fly ash is fully reacted with dilute hydrochloric acid with a concentration of 18% at a solid-liquid ratio of 1:3.2 (g / ml), and then filtered to obtain a mixture containing Silicon filter residue, and this silicon-containing filter residue is dried for use. At the same time, the obtained filtrate was evaporated and crystallized at 150°C to obtain a solid mixture containing calcium chloride and magnesium chloride crystals for subsequent use. The standby silicon-containing filter residue and the sodium hydroxide solution with a concentration of 22% are reacted at 70° C. in a ratio of 1:1.3 (g / ml) to obtain a sodium silicate-containing liquid mixture.

[0036] Get 80 kilograms of lignite, 320 kilograms of ammonium chloride, 280 kilograms of monoammonium phosphate, 250 kilograms of potassium sulfate, 5 kilograms of bentonite, 5 kilograms of trace element fertilizers (5 kilograms of solid mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com