Oil gelling agent and preparation method thereof

A technology of oil condensation agent and mesoporous silica, which is applied in chemical instruments and methods, other chemical processes, fixed on or in inorganic carriers, etc., and can solve the complex production process, slow condensation speed and secondary pollution. and other problems, to improve the catalytic efficiency, avoid the loss of enzymes, and achieve the effect of efficient activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

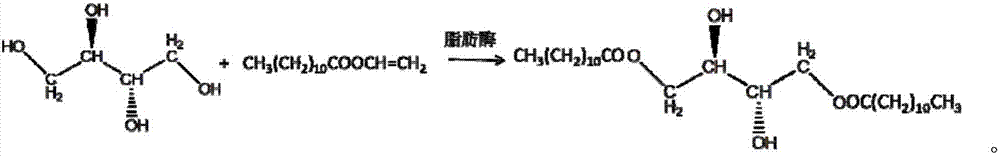

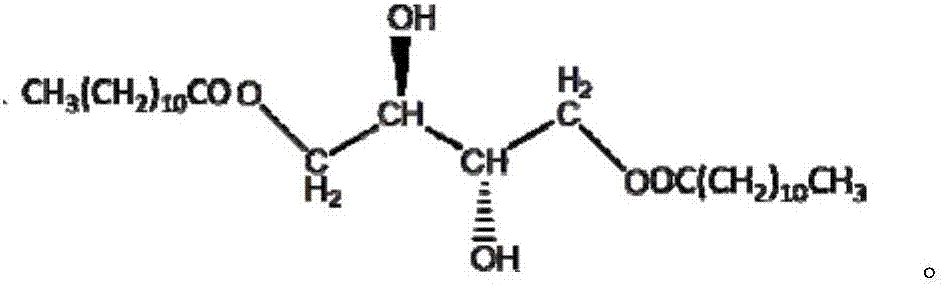

Method used

Image

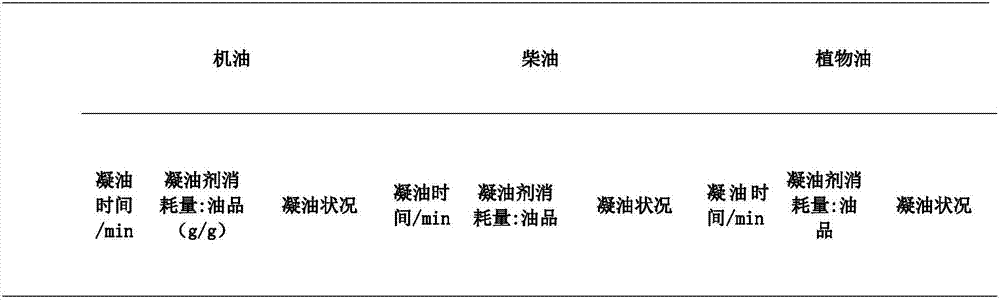

Examples

Embodiment 1

[0050] Preparation of onion-like mesoporous silica

[0051] Polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer (P123) was used as a template, and tetraethyl orthosilicate (TEOS) was used as a silicon source, and was synthesized by a hydrothermal method. The specific steps are as follows: add 4.0g of P123 into the beaker, add 150mL of 1.6M hydrochloric acid, place the beaker in a water bath at 20°C, stir with a stirring paddle at 250rpm / min for 3h, add 2g of mesitylene TMB, and stir at room temperature for 5h at 250rpm / min . After that, the temperature of the water bath was raised to 40°C, and 8.5g of TEOS was added during rapid stirring (350rpm / min). After the TEOS was mixed evenly, the speed was reduced to 250rpm / min, and stirred for 20h. After the reaction was completed, the emulsion was transferred to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and crystallized at 100° C. for 24 hours in an electric constant temperature blast drying oven....

Embodiment 2

[0053] (1) Take by weighing 1 g of onion-like mesoporous silica in Example 1 for subsequent use;

[0054] (2) Modification of mesoporous silica: Weigh 0.2 g of a certain amount of mussel plantar protein substitute dopamine, and add dopamine into 200 ml of phosphate buffer solution (100 mM, pH7.0) that has been measured. After the dopamine is fully dissolved, quickly add 1 g of mesoporous silica in step (1), stir for 3 h, centrifuge at 7000 rpm, wash with 500 ml of phosphate buffer solution and centrifuge, heat and dry at 40 ° C to obtain modified mesoporous silica 0.96 g;

[0055] (3) Preparation of immobilized lipase: Dissolve 0.5 g of the modified mesoporous silica in step (2) completely in 50 ml of phosphate buffer, add 0.5 g of lipase, stir to obtain a mixed solution, 7000 rpm Centrifuge, pour off the supernatant, then add 50ml of phosphate buffer, shake fully to dissolve the solid, then centrifuge at 7000rpm, pour off the supernatant, repeat 3 times, finally, take out 0....

Embodiment 3

[0058] (1) Take by weighing 2 g of onion-like mesoporous silica in Example 1 for subsequent use;

[0059] (2) Modification of mesoporous silica: Weigh 0.4 g of a certain amount of mussel plantar protein substitute dopamine, and add dopamine to the measured 400 ml phosphate buffer solution (100 mM, pH7.0). After the dopamine is fully dissolved, quickly add 2 g of mesoporous silica in step (1), stir for 4 h, centrifuge at 7000 rpm, wash with 500 ml of phosphate buffer solution and centrifuge, heat and dry at 40 ° C to obtain modified mesoporous silica 1.98 g;

[0060] (3) Preparation of immobilized lipase: Dissolve 1 g of the modified mesoporous silica in step (2) completely in 100 ml of phosphate buffer, add 1 g of lipase, stir to obtain a mixed solution, centrifuge at 7000 rpm, Pour off the supernatant, then add 100ml of phosphate buffer, shake fully to dissolve the solid, then centrifuge at 7000rpm, pour off the supernatant, repeat 3 times, finally, take out 1.66g of precipi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com