Hollow molecularly imprinted polymers and solid phase extraction column and preparation method and application thereof

A solid-phase extraction column and molecularly imprinted technology, which is applied in the field of preparation of hollow molecularly imprinted solid-phase extraction columns, can solve the problems of uneven distribution of imprinted sites, unfavorable elution, and too deep "embedding" to improve adsorption Efficiency, obvious adsorption effect, obvious enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

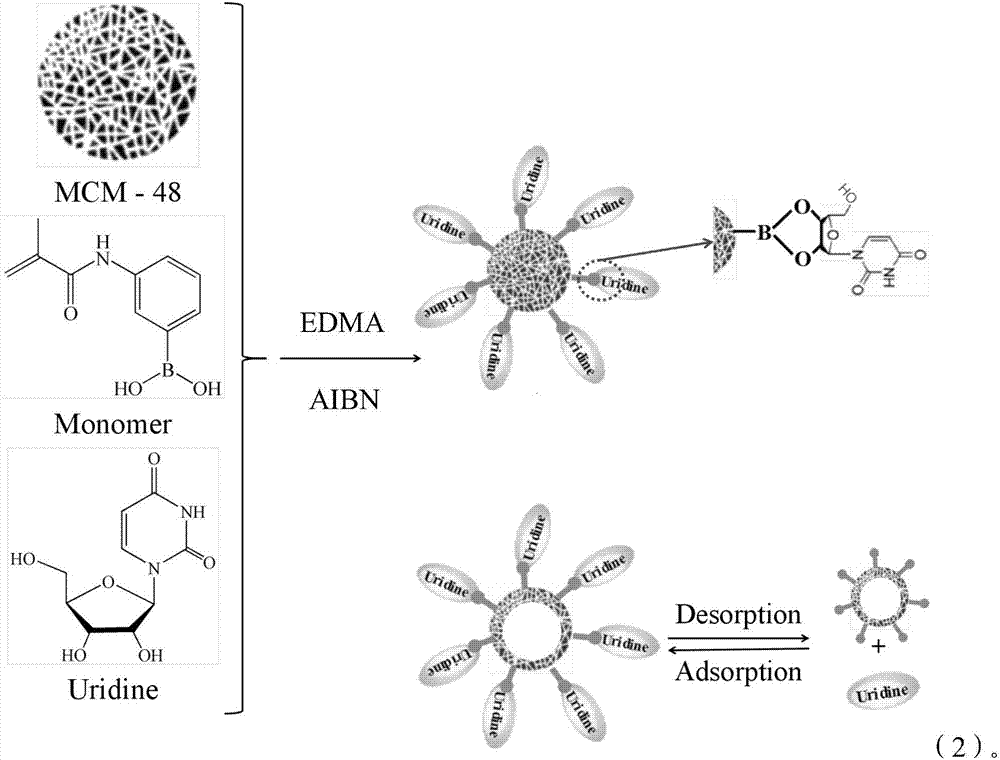

[0038] Preparation of a Boron Affinity Hollow Molecularly Imprinted Solid Phase Extraction Column

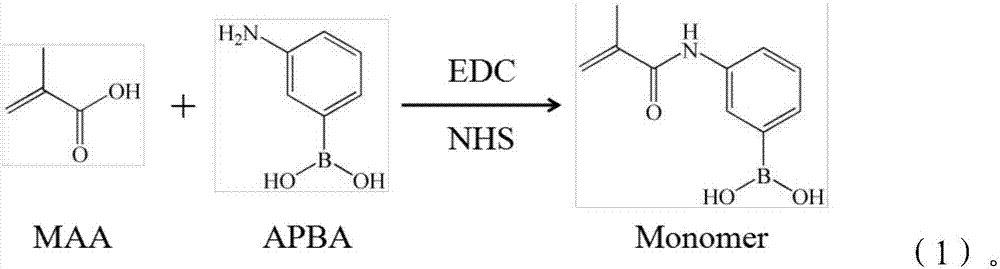

[0039] Weigh 1.00 mmol of monomeric methacrylic acid and 1.00 mmol of 3-aminophenylboronic acid respectively, mix the two evenly, and then dissolve them in 40 mL of acetonitrile, and stir at room temperature for 12 hours to obtain methacrylic acid surface-modified with nucleoside Phenylboronic acid structure with boron affinity;

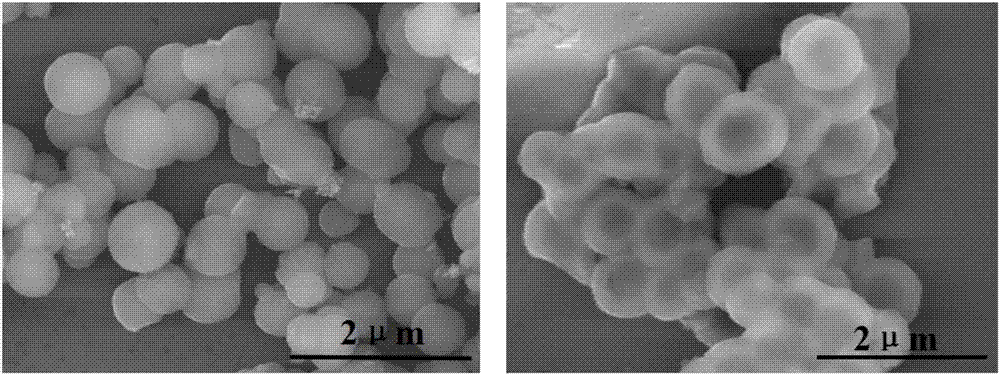

[0040] Add template uridine to the above phenylboronic acid structure in an amount of 0.25mmol, and let stand at 0°C for 4h; add 5.00mmol of cross-linking agent ethylene glycol dimethacrylate, and then add initiator azobisisobutyronitrile 0.457mmol, through N2 10min, stirred at 40°C for 1h; then, added 200mg of mesoporous molecular sieve MCM-48 to the system, ultrasonicated for 15min, and passed through N 2 Seal, stir at 40°C for 2h, at 65°C for 18h, and at 80°C for 6h to prepare polymer microspheres;

[0041] After the polymer microspheres prepared ...

Embodiment 2

[0054] Preparation of a Boron Affinity Hollow Molecularly Imprinted Solid Phase Extraction Column

[0055] Weigh 1.00mmol of monomeric methacrylic acid and 2.00mmol of 3-aminophenylboronic acid, mix the two evenly, and then dissolve them in 50mL of acetonitrile, stir at room temperature for 16h, and obtain methacrylic acid surface-modified with nucleoside Phenylboronic acid structure with boron affinity;

[0056] Add template uridine to the above phenylboronic acid structure, the addition amount is 0.4mmol, and stand at 20°C for 4h; add 4mmol of crosslinking agent ethylene glycol dimethacrylate, and then add initiator azobisisobutyronitrile 0.061 mmol, thru N 2 20min, stirring at 60°C for 2h; after that, add 400mg of mesoporous molecular sieve MCM-48 to the system, sonicate for 20min, pass N 2 Seal, stir at 60°C for 3h, at 80°C for 20h, and at 100°C for 6h to prepare polymer microspheres;

[0057] After the polymer microspheres prepared above were washed with ethanol by suc...

Embodiment 3

[0070] Preparation of a Boron Affinity Hollow Molecularly Imprinted Solid Phase Extraction Column

[0071] Weigh 1.00mmol of monomeric methacrylic acid and 3.00mmol of 3-aminophenylboronic acid, mix the two evenly, and then dissolve them in 60mL of acetonitrile, stir at room temperature for 18h, and obtain methacrylic acid surface-modified with nucleoside Phenylboronic acid structure with boron affinity;

[0072] Add template uridine to the above phenylboronic acid structure in an amount of 0.25 mmol, and let it stand at 30°C for 6 hours; add 10 mmol of crosslinking agent ethylene glycol dimethacrylate, and then add 0.12 mmol of initiator azobisisobutyronitrile , through N 2 30min, stirring at 80°C for 1h; after that, add 600mg of mesoporous molecular sieve MCM-48 to the system, ultrasonic for 30min, pass N 2 Seal, stir at 70°C for 4h, at 80°C for 20h, and at 90°C for 8h to prepare polymer microspheres;

[0073] After the polymer microspheres prepared above were washed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com