Preparation method, product and application of phthalate molecularly imprinted polymer

A technology of phthalic acid and phthalic acid di, which is applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., and can solve problems such as irregular imprinted polymer particles and template leakage , achieve the effect of shortening the detection time, regular shape and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

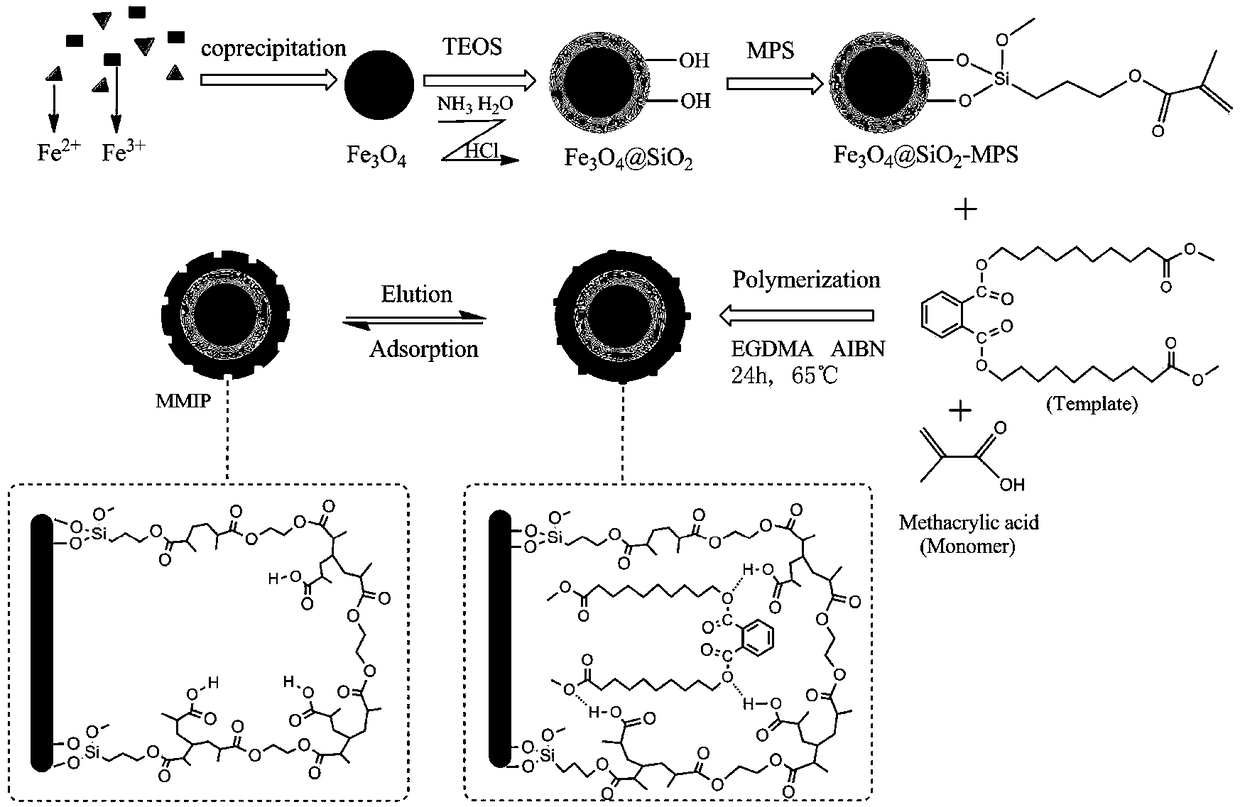

[0045] Embodiment 1 (see figure 1 )

[0046] 1. Simulation of molecularly imprinted polymer pre-assembly system

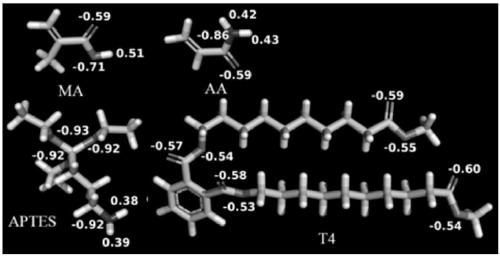

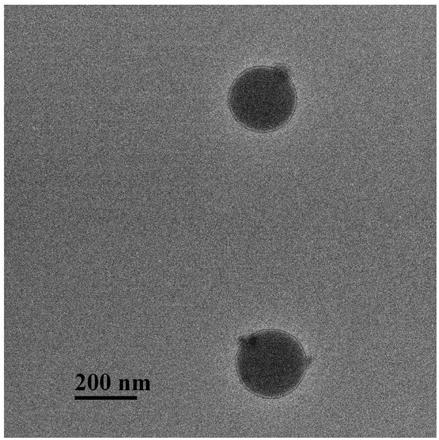

[0047] 1. Using Gaussian software, geometrically optimize all template molecules and functional monomer molecules at the B97D3 / 6-31+g* level, and calculate the NBO charge distribution of the molecules to analyze the possible combination of templates and functional monomers site. The optimized structure and charge distribution of template molecules and functional monomers are as follows: figure 2 shown.

[0048] 2. Optimize the structure of the composite system composed of the interaction between the template and the functional monomer at the B97D3 / 6-31+g* level and calculate its energy, compare the strength of the interaction between the template and the functional monomer through the binding energy ΔE, and select the function Monomer; the calculation of binding energy ΔE is shown in formula (1):

[0049] ΔE=E complex –E template –nE monomer (1)

[0050]...

Embodiment 2

[0074] 1. The simulation of the molecularly imprinted polymer pre-assembly system is the same as that in Example 1;

[0075] 2. The preparation of magnetic nanoparticles (Fe3O4@SiO2-MPS) is the same as in Example 1;

[0076] 3. The preparation of the virtual template is the same as in Example 1;

[0077] 4. Preparation of Magnetic Molecularly Imprinted Polymers

[0078] Dissolve 0.2mmol of bis(10-methoxy-10-oxodecanyl)phthalate and 0.8mmol of MAA in 25mL of toluene to fully mix the template molecules and monomers, then let stand at room temperature for 4h to obtain the prepared polymer; adding magnetic nanoparticles (Fe 3 o 4 @SiO 2 - MPS) 0.15 mg, cross-linking agent EGDMA 4.0 mmol and initiator AIBN 17.2 mg, mix uniformly, pass nitrogen gas for 5 min, seal, polymerize at 65° C. for 24 h, and magnetically separate to obtain an imprinted polymer. The preparation method of non-magnetic molecularly imprinted polymer (M-NIP) is the same as that of M-MIP except that no templa...

Embodiment 3

[0083] 1. The simulation of the molecularly imprinted polymer pre-assembly system is the same as that in Example 1;

[0084] 2. Magnetic nanoparticles (Fe 3 o 4 @SiO 2 -MPS) is prepared with embodiment 1;

[0085] 3. The preparation of the virtual template is the same as in Example 1;

[0086] 4. Preparation of Magnetic Molecularly Imprinted Polymers

[0087] Dissolve 0.2mmol of bis(10-methoxy-10-oxodecanyl)phthalate and 0.8mmol of MAA in 30mL of toluene to fully mix the template molecules and monomers, then let stand at room temperature for 4h to obtain the prepared polymer; adding magnetic nanoparticles (Fe 3 o 4 @SiO 2- MPS) 0.2mg, cross-linking agent EGDMA 4.0mmol and initiator AIBN 21.5mg, mix well, pass nitrogen gas for 5min, seal, and polymerize at 65°C for 24h to obtain imprinted polymer. The non-magnetic molecularly imprinted polymer (M-NIP) was prepared according to the above method except that no template was added. The elution of the template molecule was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com