Colorable and high-conductivity PET (Polyethylene Terephthalate) master batch and preparation method thereof

A masterbatch, high temperature technology, applied in the field of PET masterbatch preparation, can solve the problems of poor mechanical properties, high price, and high amount of conductive carbon black added, and achieve the effects of excellent conductivity, strong spinnability, and easy spinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

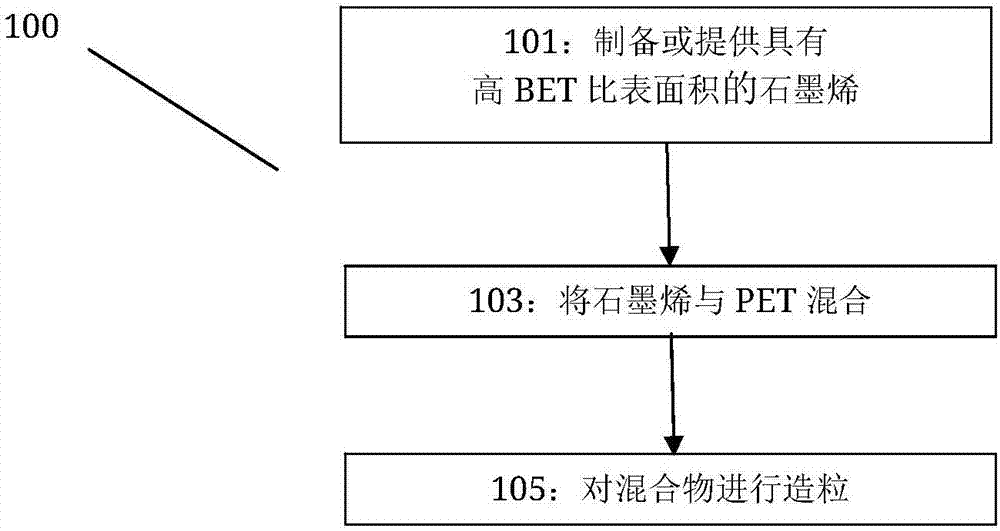

[0026] The first embodiment of the present invention provides a method 100 for preparing a graphene-containing PET masterbatch. like figure 1 As shown, the preparation method 100 of the PET master batch of the present invention includes: 101, prepare or provide graphene with a high BET specific surface area; 103, mix the graphene with PET to obtain a PET / graphene mixture; 105, for The PET / graphene mixture is granulated to obtain the PET masterbatch.

[0027] In the present invention, the graphene preferably has a high BET specific surface area. In the present invention, the high BET specific surface area is at 400m 2 / g or more, preferably at 450m 2 / g or more.

[0028] According to a preferred embodiment of the present invention, the graphene is in the form of powder and is prepared by a redox method. For example, use 1 part of graphite and 20 parts of sulfuric acid with a concentration of 65wt%, add 3 parts of potassium permanganate at 8°C, then raise the temperature to...

example 1

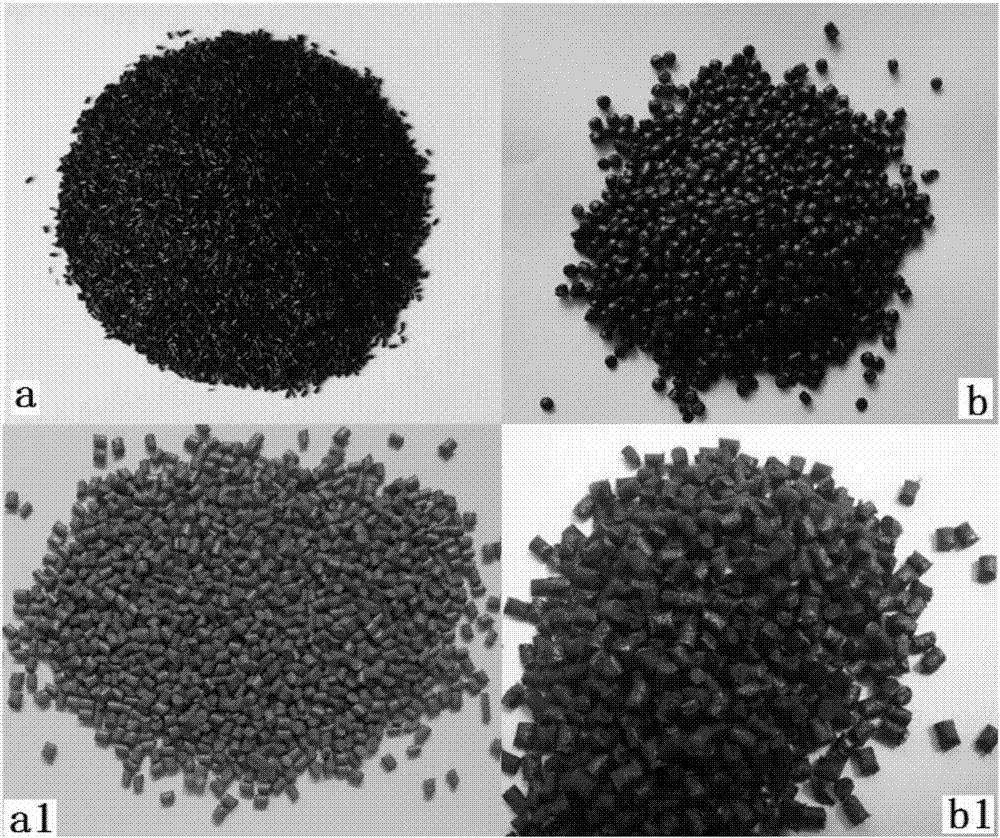

[0040] (1) The temperature of the internal mixer is raised to 270°C, and the temperature is kept constant. Weigh 2000g of PET raw material, 100g of BET is 400m 2 / g graphene, join in the banbury mixer with constant temperature and carry out mixing, mixing 15min standby.

[0041] (2) Set the temperature of the forced feeding granulator to 265°C, add the mixed materials in (1) into the granulator with constant temperature, and then start extrusion granulation, and finally obtain a colorable graphene PET conductive mother grain.

example 2

[0043] (1) The temperature of the internal mixer is raised to 270°C, and the temperature is kept constant. Weigh 2000g of PET raw material, 60g of BET is 450m 2 / g graphene, join in the banbury mixer with constant temperature and carry out mixing, mixing 15min standby.

[0044] (2) Set the temperature of the forced feeding granulator to 265°C, add the mixed materials in (1) into the granulator with constant temperature, and then start extrusion granulation, and finally obtain a colorable graphene PET conductive mother grain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com