A waterborne polyurethane leather finish with anti-biofouling properties

A water-based polyurethane and leather finishing agent technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, leather surface treatment, etc., can solve problems such as poor water resistance of polyurethane films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

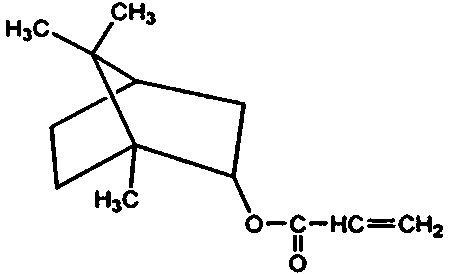

[0020] Example 1: Preparation of isobornyl molecular chain extender containing dihydroxy; the specific operation method is as follows: add 15.61 g of isobornyl acrylate, 2.16 g of 1-thio-2,3-propanediol and 0.3290 g of Photocatalyst 2-hydroxy-2-methylpropiophenone, 65 mL tetrahydrofuran; put nitrogen into the weighing bottle for 20 min, seal it, stir it with a magnetic stirrer for 5 min, then put the weighing bottle into the ultraviolet radiation box, React for 2 h under the irradiation of ultraviolet light, remove most of the solvent by rotary evaporation, and then precipitate the concentrated reaction product in water twice, 4 h each time, pour off most of the water, and dry in vacuum for 24 h to obtain The isoborneol molecular chain extender;

[0021] After adding 20 g of polytetrahydrofuran ether (Mn=2000), 13.345 g of diphenylmethane diisocyanate and 350 ml of tetrahydrofuran solvent into a 500 mL three-neck flask, mechanically stirred under nitrogen protection, 60 o C f...

Embodiment 2

[0022] Example 2: Preparation of isobornyl molecular chain extender containing dihydroxy; the specific operation method is as follows: add 16.87 g of isobornyl acrylate, 2.16 g of 1-thio-2,3-propanediol and 0.1290 g of Photocatalyst 2-hydroxy-2-methylpropiophenone, 70 mL tetrahydrofuran; nitrogen was introduced into the weighing bottle for 20 min, sealed, stirred with a magnetic stirrer for 5 min, and then the weighing bottle was placed in an ultraviolet irradiation box. React for 2 h under the irradiation of ultraviolet light, remove most of the solvent by rotary evaporation, and then precipitate the concentrated reaction product in water twice, 4 h each time, pour off most of the water, and dry in vacuum for 24 h to obtain The isoborneol molecular chain extender;

[0023] After adding 20 g of polycarbonate diol (Mn=1000), 13 g of isophorone diisocyanate and 350 ml of tetrahydrofuran solvent into a 500 mL three-neck flask, mechanically stirred under nitrogen protection, 60 o...

Embodiment 3

[0024] Example 3: Preparation of isobornyl molecular chain extender containing dihydroxy; the specific operation method is as follows: add 10.40 g of isobornyl acrylate, 1.08 g of 1-thio-2,3-propanediol and 0.2342 g of Photocatalyst 2-hydroxy-2-methylpropiophenone, 60 mL tetrahydrofuran; put nitrogen into the weighing bottle for 20 min, seal it, stir it with a magnetic stirrer for 5 min, then put the weighing bottle into the ultraviolet radiation box, React for 2 h under the irradiation of ultraviolet light, remove most of the solvent by rotary evaporation, and then precipitate the concentrated reaction product in water twice, 4 h each time, pour off most of the water, and dry in vacuum for 24 h to obtain The isoborneol molecular chain extender;

[0025] After adding 20 g of polytetrahydrofuran ether (Mn=2000), 9.285 g of hexamethylene diisocyanate and 350 ml of tetrahydrofuran solvent into a 500 mL three-neck flask, mechanically stirred under nitrogen protection, 60 o C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com