A kind of corrosion-resistant and anti-fouling copper-based amorphous/carbon nanotube composite material and preparation method thereof

A technology of carbon nanotube composite and carbon nanotube, which is applied in the direction of nanotechnology, nanotechnology, metal material coating technology, etc., can solve the problems of insufficient corrosion resistance and anti-biofouling performance of copper-based materials, and achieve the improvement of anti-biofouling Fouling performance, improved corrosion resistance, low porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

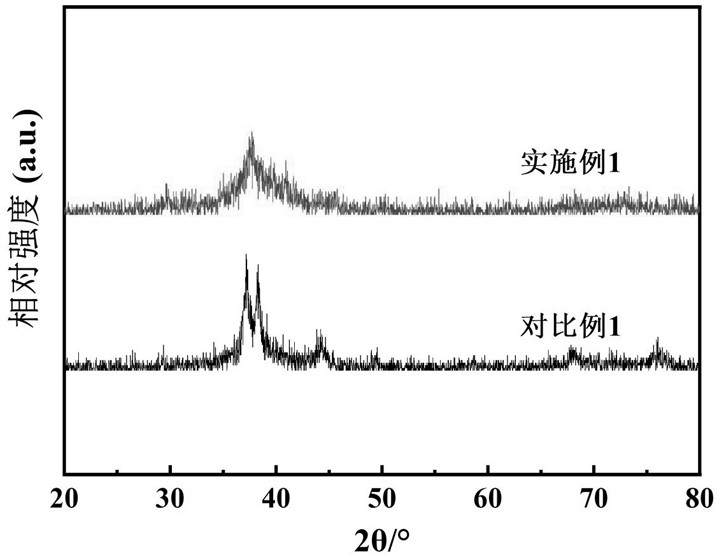

Embodiment 1

[0028] A corrosion-resistant and antifouling copper-based amorphous / carbon nanotube composite material is formed by compounding 97wt% copper-based amorphous and 3wt% carbon nanotubes; the weight percentage of the copper-based amorphous composition is as follows: 16wt% Al , 15wt% Ti, 14wt% Zr, 5wt% Si, 4wt% Mo, and the balance is Cu; the carbon nanotubes are silver-doped single-armed carbon nanotubes.

[0029] The above-mentioned copper-based amorphous / carbon nanotube composite material is prepared by the following steps:

[0030] The first step: according to the above-mentioned copper-based amorphous composition and weight ratio, weigh copper-titanium alloy, aluminum-titanium alloy, pure zirconium, pure molybdenum block and single crystal silicon, and sequentially mix the pure molybdenum with the principle of high melting point and then low melting point. , pure zirconium, single crystal silicon, copper-titanium alloy and aluminum-titanium alloy are added to the vacuum inducti...

Embodiment 2

[0037] A corrosion-resistant and antifouling copper-based amorphous / carbon nanotube composite material is formed by compounding 96wt% copper-based amorphous and 4wt% carbon nanotubes; the weight percentage of the copper-based amorphous composition is as follows: 16wt% Al , 15wt% Ti, 14wt% Zr, 5wt% Si, 4wt% Mo, and the balance is Cu; the carbon nanotubes are silver-doped single-armed carbon nanotubes.

[0038] The preparation method of the copper-based amorphous / carbon nanotube composite material in this example, the application and construction method of the composite material in the preparation of corrosion-resistant and anti-biofouling coatings are all the same as in Example 1.

Embodiment 3

[0040]A corrosion-resistant and antifouling copper-based amorphous / carbon nanotube composite material is formed by compounding 98wt% copper-based amorphous and 2wt% carbon nanotubes; the weight percentage of the copper-based amorphous composition is as follows: 16wt% Al , 15wt% Ti, 14wt% Zr, 5wt% Si, 4wt% Mo, and the balance is Cu; the carbon nanotubes are silver-doped single-armed carbon nanotubes.

[0041] The preparation method of the copper-based amorphous / carbon nanotube composite material in this example, the application and construction method of the composite material in the preparation of corrosion-resistant and anti-biofouling coatings are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com