High-mobility transistor based on PMMA doped micro-molecule and preparation method thereof

A high-mobility, transistor-based technology, applied in the field of organic electronics, can solve problems such as hindering the further use of devices, large surface roughness, and reduced mobility, and achieve the effects of easy industrialization, simple preparation methods, and improved device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

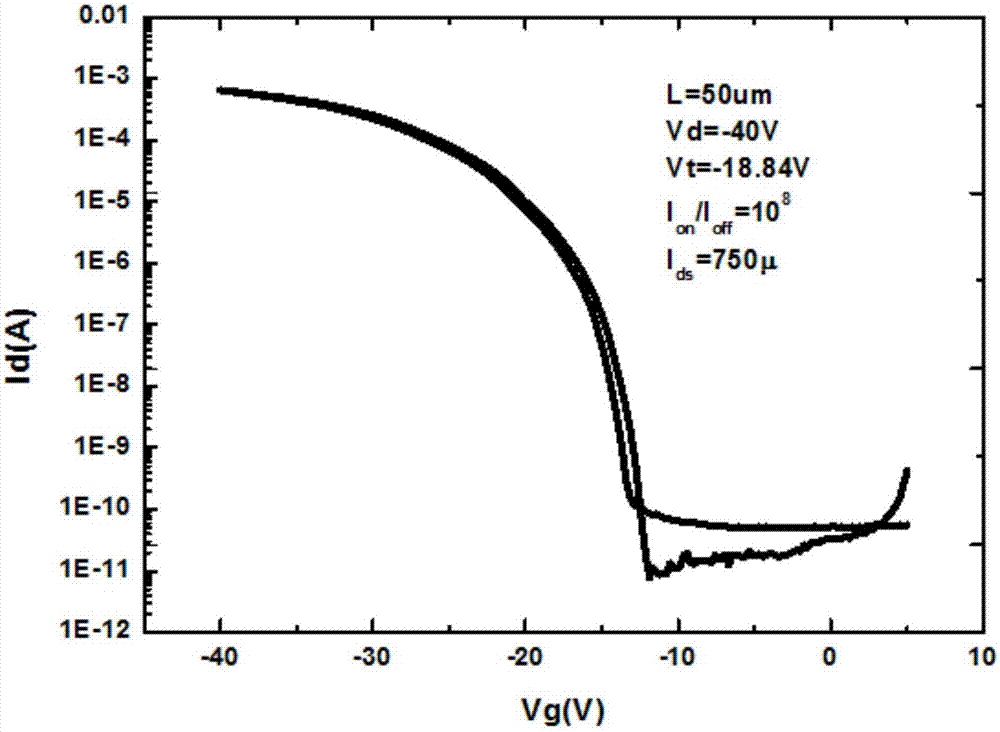

Embodiment 1

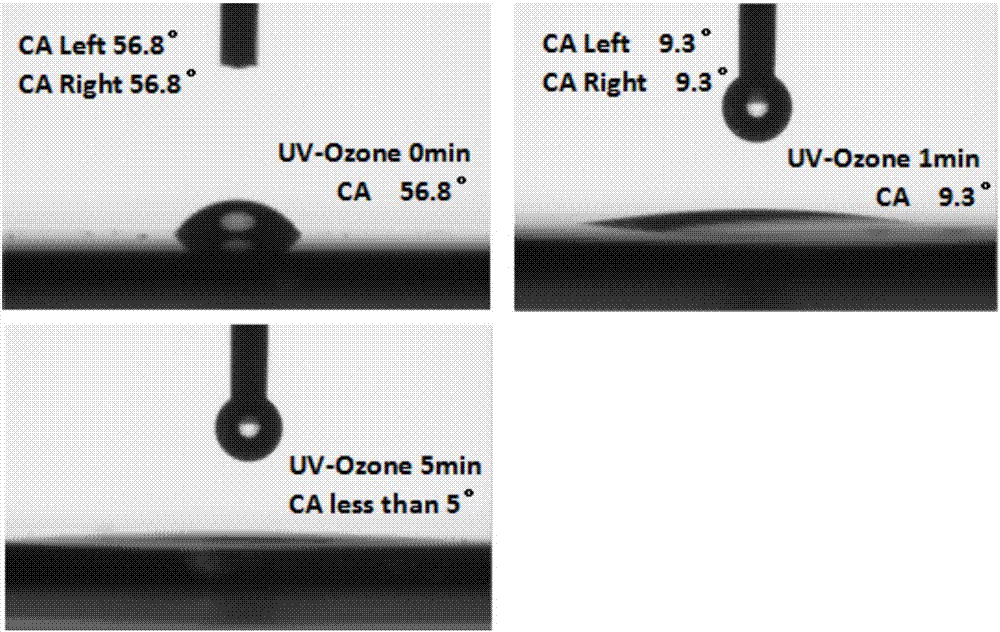

[0036] A method for preparing a high-mobility transistor based on PMMA-doped small molecules described in this embodiment comprises the following steps:

[0037] S1: Preparation of C8-BTBT and PMMA mixed solution: use C8-BTBT and PMMA as solute and chlorobenzene as solvent to prepare a mixed solution of 0.5% mass ratio of C8-BTBT and 0.5% mass ratio of PMMA, and the prepared solution is sonicated for 10 minutes use, ready-to-use;

[0038] S2: Substrate cleaning: Select a P-type heavily doped silicon wafer containing silicon dioxide, cut it into a square with a side length of 1.5 cm with a silicon wafer knife, and clean it by ultrasonic: put acetone, isopropanol, and Deionized water, acetone, isopropanol, deionized water, and then rinse it with deionized water for two minutes to remove impurities such as organic matter on the surface, spray nitrogen with a nitrogen gun to dry the surface of the silicon wafer with deionized water, and then It is dried in an oven;

[0039] S3: ...

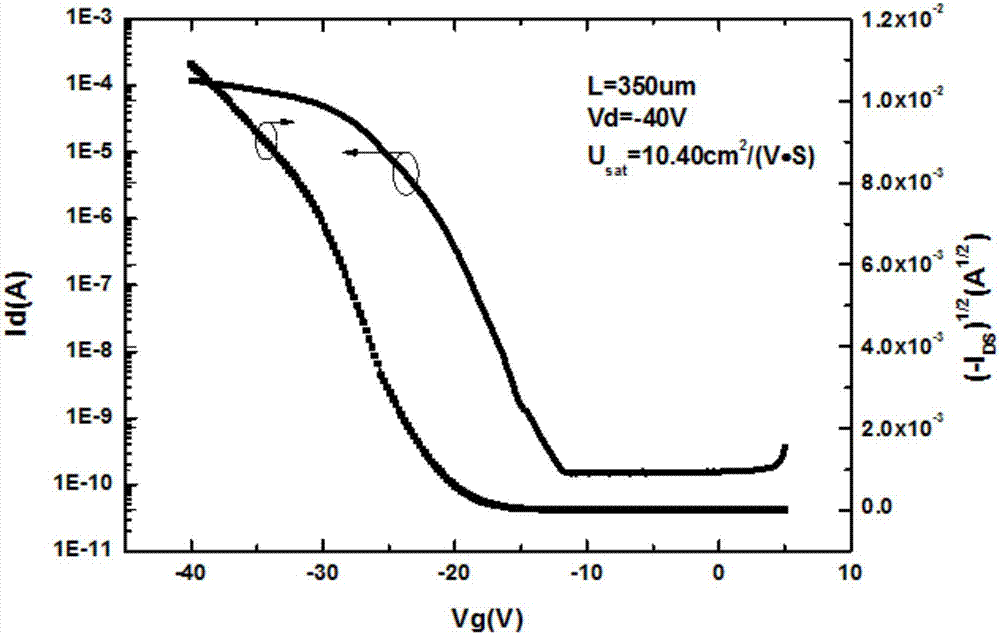

Embodiment 2

[0046] A method for preparing a high-mobility transistor based on PMMA-doped small molecules described in this embodiment comprises the following steps:

[0047] S1: Preparation of C8-BTBT and PMMA mixed solution: use C8-BTBT and PMMA as solute and chlorobenzene as solvent to prepare a mixed solution of 0.5% mass ratio of C8-BTBT and 0.5% mass ratio of PMMA, and the prepared solution is sonicated for 10 minutes use, ready-to-use;

[0048] S2: Substrate cleaning: Select a P-type heavily doped silicon wafer containing silicon dioxide, cut it into a square with a side length of 1.5 cm with a silicon wafer knife, and clean it by ultrasonic: put acetone, isopropanol, and Deionized water, acetone, isopropanol, deionized water, and then rinse it with deionized water for two minutes to remove impurities such as organic matter on the surface, spray nitrogen with a nitrogen gun to dry the surface of the silicon wafer with deionized water, and then It is dried in an oven;

[0049] S3: ...

Embodiment 3

[0055] A method for preparing a high-mobility transistor based on PMMA-doped small molecules described in this embodiment comprises the following steps:

[0056] S1: Preparation of C8-BTBT and PMMA mixed solution: use C8-BTBT and PMMA as solute and chlorobenzene as solvent to prepare a mixed solution of 0.5% mass ratio of C8-BTBT and 0.5% mass ratio of PMMA, and the prepared solution is sonicated for 10 minutes use, ready-to-use;

[0057] S2: Substrate cleaning: Select a P-type heavily doped silicon wafer containing silicon dioxide, cut it into a square with a side length of 1.5 cm with a silicon wafer knife, and clean it by ultrasonic: put acetone, isopropanol, and Deionized water, acetone, isopropanol, deionized water, and then rinse it with deionized water for two minutes to remove impurities such as organic matter on the surface, spray nitrogen with a nitrogen gun to dry the surface of the silicon wafer with deionized water, and then It is dried in an oven;

[0058] S3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com