Making method of dried turnip

A production method and technology of dried radish, applied in food drying, food ingredients as antimicrobial preservation, food science, etc., can solve the problems of no longer pure flavor, lack of technological innovation, long processing time, etc., to prevent water from passing through the cell membrane Excessive penetration, prevent excessive water loss, and speed up fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

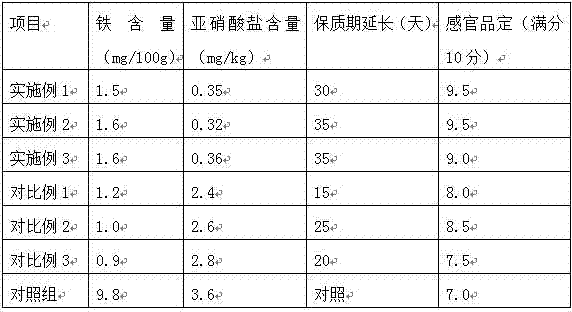

Embodiment 1

[0016] A method for preparing dried radish, which is made from the following raw materials in parts by weight: 100 parts of fresh radish, 5 parts of bean sprout juice, 4.5 parts of aloe vera powder, 3.5 parts of soybean powder, 3.0 parts of sea salt, 2.5 parts of white sugar, 1.5 parts of Chinese pepper, 1.5 parts of star anise, 1.3 parts of red pepper, 0.5 parts of cumin powder, 0.3 parts of pepper, 0.2 parts of lactic acid bacteria, including the following production steps:

[0017] (1) Clean the fresh radish, cut into strips 10-12 cm in length and 2-3 cm in width, and soak for 20 minutes in a soaking liquid. The soaking liquid is composed of honeysuckle, mangosteen, chrysanthemum, isatis root, and Mingjue. Rinse the soaked radish strips with clean water and put them in a 50℃ oven to dry the surface moisture;

[0018] (2) Grind the sea salt into 0.1-0.3 mm particles, and evenly spread on the dried radish strips. After marinating for 1 day, knead the radish strips, pour out the wa...

Embodiment 2

[0024] A method for preparing dried radish, which is made from the following raw materials in parts by weight: 110 parts of fresh radish, 6 parts of bean sprout juice, 5.0 parts of aloe vera powder, 3.7 parts of soybean powder, 3.5 parts of sea salt, 3.0 parts of white sugar, 2.0 parts of Chinese pepper, 1.7 parts star anise, 1.4 parts red pepper, 0.55 parts cumin powder, 0.4 parts pepper, 0.25 parts lactic acid bacteria, including the following production steps:

[0025] (1) Clean the fresh radish, cut into strips with a length of 10-12 cm and a width of 2-3 cm, and soak for 25 minutes in a soaking liquid consisting of honeysuckle, mangosteen, chrysanthemum, Radix isatidis, and Mingjue Rinse the soaked radish strips with clean water and put them in a 55℃ oven to dry the surface moisture;

[0026] (2) Grind the sea salt into 0.1-0.3 mm particles, and evenly spread on the dried radish strips. After marinating for 1 day, knead the radish strips, pour out the water from the pickling, ...

Embodiment 3

[0032] A method for making dried radish, which is made from the following raw materials in parts by weight: 120 parts of fresh radish, 7 parts of bean sprout juice, 5.5 parts of aloe vera powder, 4.0 parts of soybean powder, 4.0 parts of sea salt, 3.5 parts of white sugar, 2.5 parts of Chinese pepper, 2.0 parts star anise, 1.5 parts red pepper, 0.6 parts cumin powder, 0.5 parts pepper, 0.3 parts lactic acid bacteria, including the following production steps:

[0033] (1) Wash the fresh radishes, cut them into strips 10-12 cm in length and 2-3 cm in width, and soak them for 30 minutes in a soaking solution consisting of honeysuckle, mangosteen, chrysanthemum, isatis root, and Mingjue Rinse the soaked radish strips with clean water and put them in a 60℃ oven to dry the surface moisture;

[0034] (2) Grind the sea salt into 0.1-0.3 mm particles, and evenly spread on the dried radish strips. After marinating for 2 days, knead the radish strips, pour out the water from the pickling, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com