High-quality nonmetallic sand-blasting abrasive circulating device

A circulation device, non-metallic technology, applied in the field of high-quality non-metallic sandblasting abrasive circulation device, can solve the problems of easy agglomeration of abrasives, affect the quality of sandblasting, damage the substrate, etc., to prolong the continuous sandblasting time and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

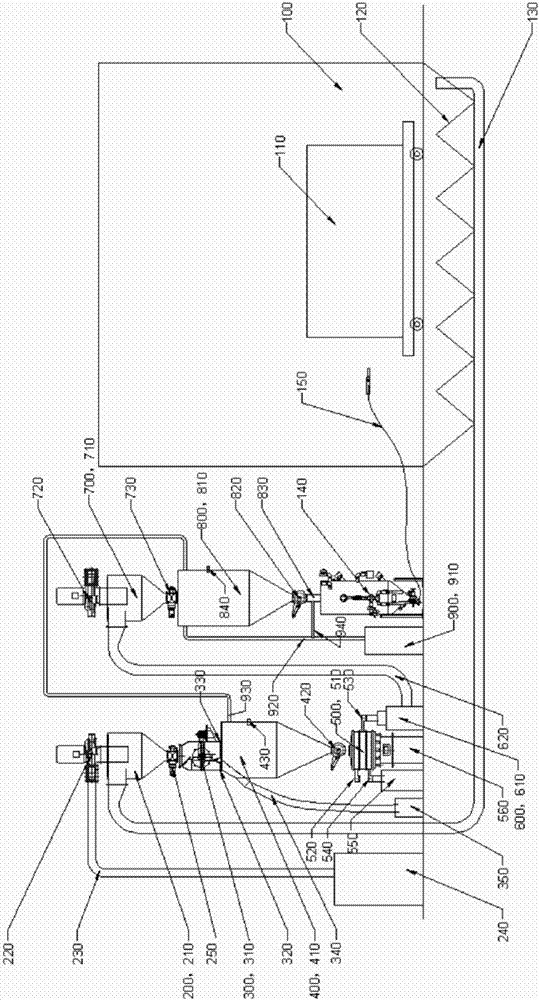

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] Carbon fiber surfaces and circuit boards have high requirements for sandblasting. In order to obtain an appropriate surface roughness, it is necessary to choose a suitable abrasive. Factors such as the type, hardness, size and impurities of the abrasive will affect the sandblasting effect.

[0037] Such as figure 1 As shown, the high-quality non-metallic sandblasting abrasive circulation device includes a sandblasting chamber 100 for sandblasting the workpiece surface 110. The bottom of the sandblasting chamber 100 is connected with the sand return device 200, the impurity removal device, and the The sand lifting device 700, the material storage device 2 800 and the sandblasting main machine 140 are connected in series. The impurity removal device includes the iron removal device 300, the material storage device 1 400, the particle size separation device 500 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com