High-doped industrial waste residue cement and preparation method thereof

A technology of industrial waste slag and cement, applied in the direction of cement production, etc., can solve the problems of small waste slag utilization, unstable quality, high cost, etc., and achieve the effects of avoiding resource waste and environmental pollution, easy promotion and application, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The method for preparing high-mixed industrial waste slag cement of the present invention includes the following steps:

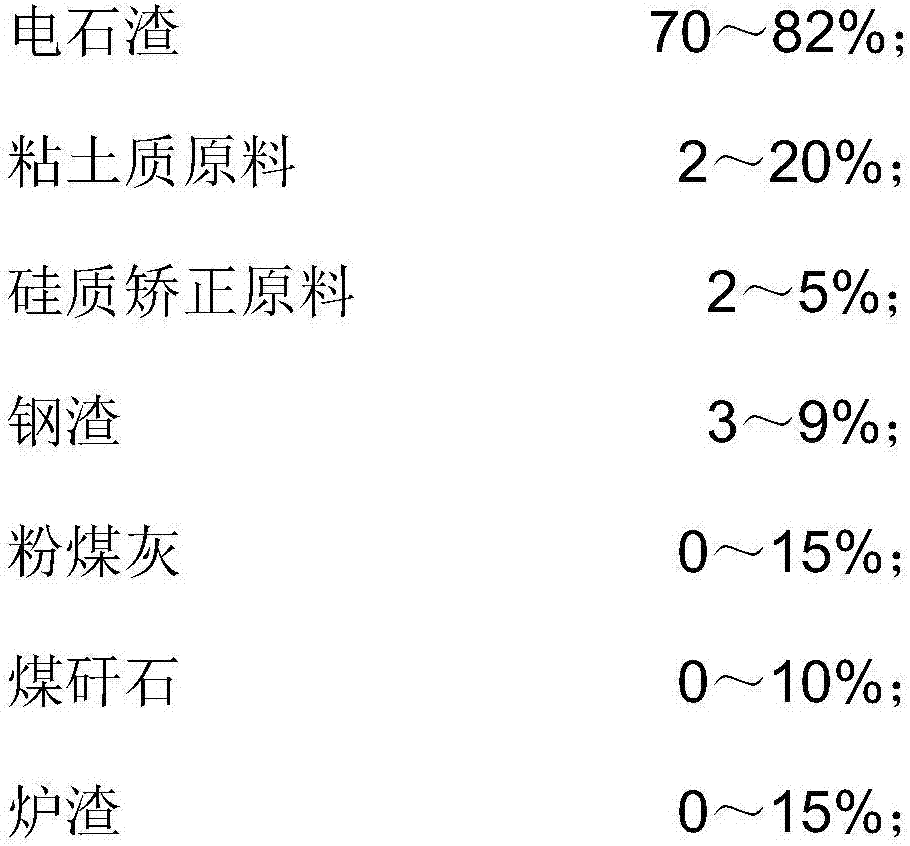

[0039] ① Preparation of raw meal: the mass ratio of 70-82% calcium carbide slag, 2-20% clay raw material (clay or clay ore), 2 to 5% siliceous correction raw material (silica or sandstone), 3-9 % Steel slag, 0-15% fly ash, 0-10% coal gangue and 0-15% slag are used to grind each component raw material through the raw meal grinding system and homogenize;

[0040] Among them, the water mass ratio of the raw meal is: calcium carbide slag ≤ 10%, clay raw material ≤ 10%, siliceous correction raw material ≤ 8%, steel slag ≤ 8%, fly ash ≤ 3%, coal gangue ≤ 8%, slag ≤ 6%.

[0041] ②Clinker calcination: Put the homogenized raw meal in step ① into the kiln, and use the mature new dry production process to calcine the mature meal;

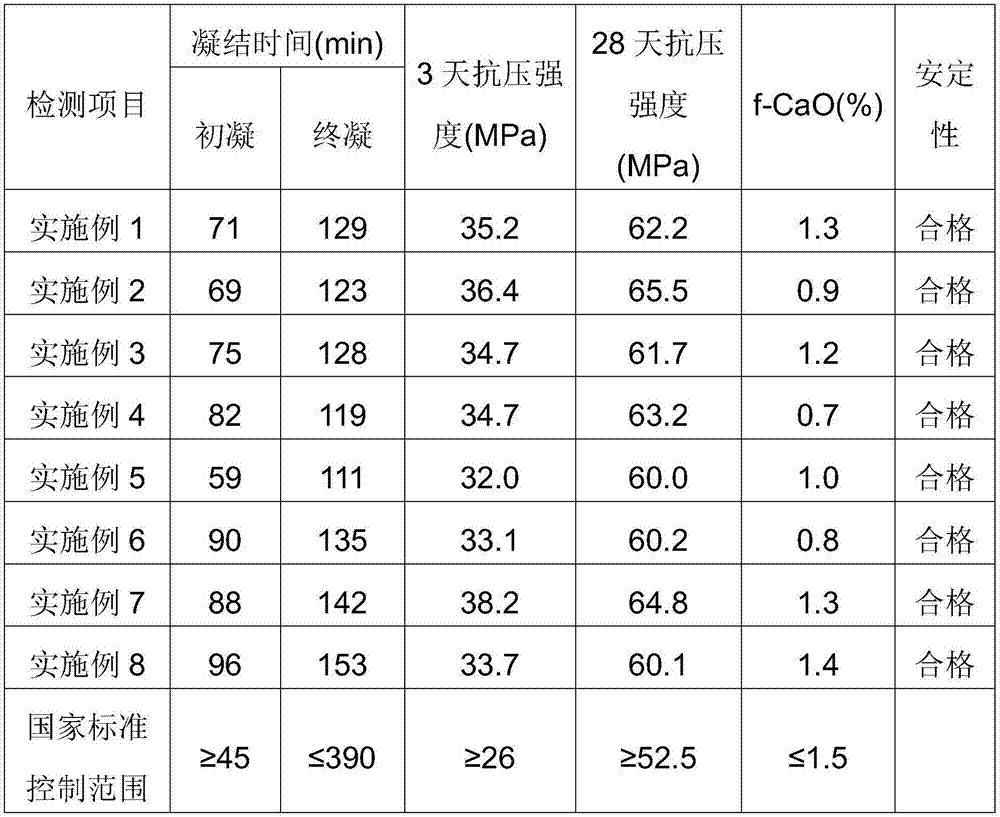

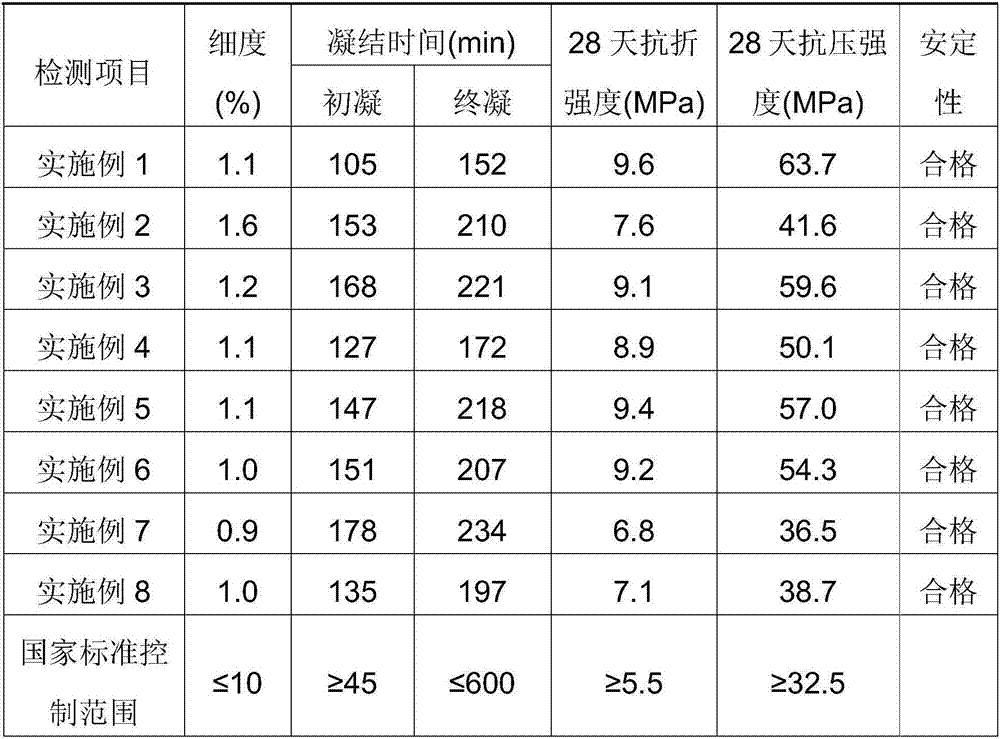

[0042] To prepare high-mixed industrial waste slag cement, in step ②, the clinker uses the following quality control indicators to control...

Embodiment 1

[0052] The raw materials of each component are proportioned and ground, and the mass parts of each component are: 74% of calcium carbide slag, 6.6% of steel slag, 16% of clay raw materials, and 3.4% of siliceous raw materials.

[0053] Put the homogenized raw meal into the kiln, and use the new dry production process to calcinate the mature meal;

[0054] The sintered clinker with a mass ratio of 99.2 parts was mixed with 0.8 parts of desulfurized gypsum for cement grinding to produce cement.

Embodiment 2

[0056] The raw materials of each component are proportioned and ground, and the mass parts of each component are: 82% calcium carbide slag, 3% steel slag, 2% clay raw material, 3.5% siliceous raw material, and 9.5% slag.

[0057] Put the homogenized raw meal into the kiln, and use the new dry production process to calcinate the mature meal;

[0058] The sintered clinker with a mass ratio of 51.5 parts was mixed with 3.5 parts of desulfurized gypsum and 45 parts of slag, and cement was milled to produce cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial setting time | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com