Haze-removal interior wall latex paint and preparation method thereof

A technology of interior wall latex paint and oil emulsion, applied in the field of coatings, can solve the problems of inability to absorb air dust, small particles, limited indoor air purification effect, and failure to meet low VOC standards, so as to improve indoor air environment and high contrast ratio , Low VOC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned haze removal interior wall latex paint comprises the following steps:

[0035] 1) Premixing: Add water and dispersant to the disperser, mix evenly, then add modified hydroxyethyl cellulose, mix evenly, then add wetting agent, filler, rutile titanium dioxide and nano tourmaline powder, then add pH Regulator, mix well;

[0036] 2) Thinning: Sampling and testing, when the particle size is less than 50 μm, add film-forming aids, bactericides, preservatives and thickeners, mix well, then add hydrophobic and oil-repellent emulsion, functional additives and defoamers, mix Uniformly, get the interior wall latex paint that removes haze.

[0037] Preferably, the preparation method of the above-mentioned haze removal interior wall latex paint may further comprise the steps:

[0038] 1) Premixing stage: add water and dispersant to the disperser, adjust the speed to 400-600r / min, stir for 1-3min, then add modified hydroxyethyl cellulose, s...

Embodiment 1

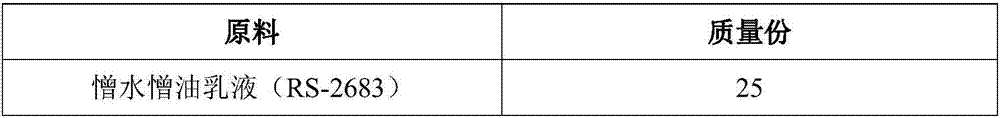

[0042] A kind of haze removal interior wall latex paint, its raw material composition is as follows:

[0043] Table 1 Raw material composition table of haze removal interior wall latex paint

[0044]

[0045]

Embodiment 2

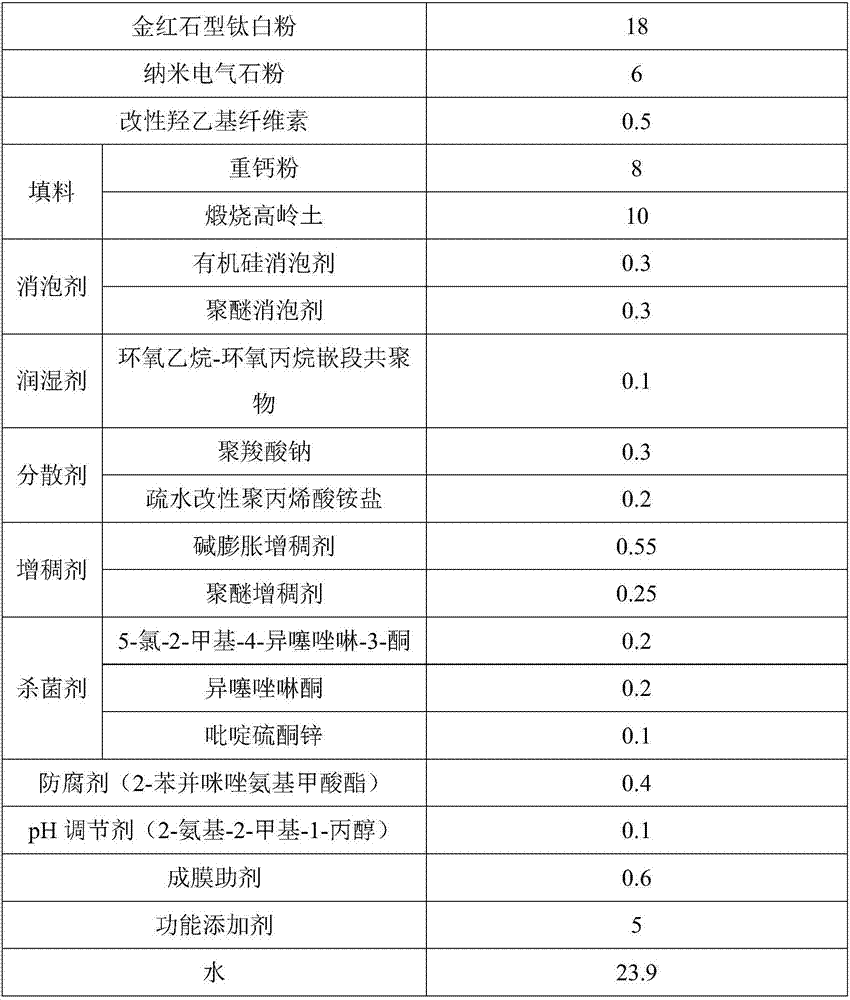

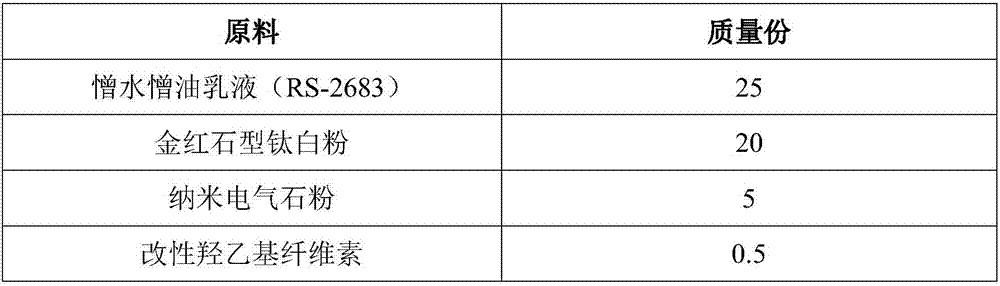

[0047] A kind of haze removal interior wall latex paint, its raw material composition is as follows:

[0048] Table 2 Raw material composition table of haze removal interior wall latex paint

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com