Transmission electron microscope in-situ nanomechanical tensile testing sample bonding method

A technology of transmission electron microscopy and tensile testing, which is applied in the preparation of test samples, testing the strength of materials by applying stable tension/pressure, and analyzing materials by measuring secondary emissions. The device cannot be reused and the cost is high, so as to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

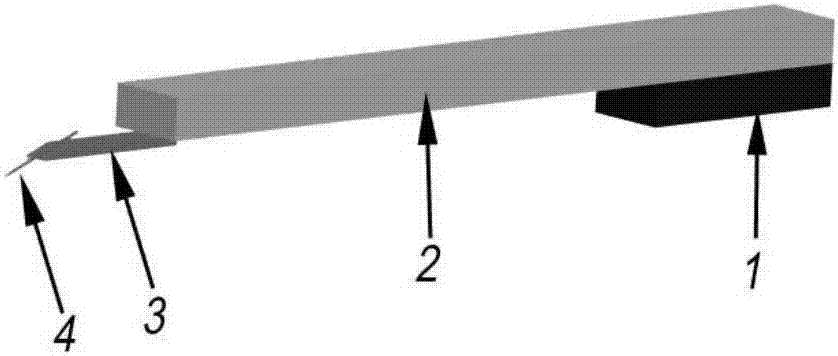

[0035] Fabricate micromechanical manipulation devices capable of micro-movement under an optical microscope, such as figure 1 As shown, the micro-mechanical moving device uses the three-coordinate micro-moving platform of another optical microscope, and the cantilever beam is made of plastic. The length of the cantilever beam is 2-2.5cm, the width is 9-10mm, and the height is 3.5-4mm. The counterweight is made of glass block, and the weight is 30-35g. The first-level operation tool is a stainless steel needle or toothpick, and the tip curvature radius is 0.1-0.2mm; the second-level operation tool is hair, and the tip curvature radius is 10-15μm. Fix with epoxy glue.

[0036] Put the 300-mesh micro-grid used in the preparation of the transmission electron microscope sample into alcohol for ultrasonic cleaning for 20-30 minutes, so that the supporting film of the micro-grid or ultra-thin micro-grid is removed, and the copper grid remains.

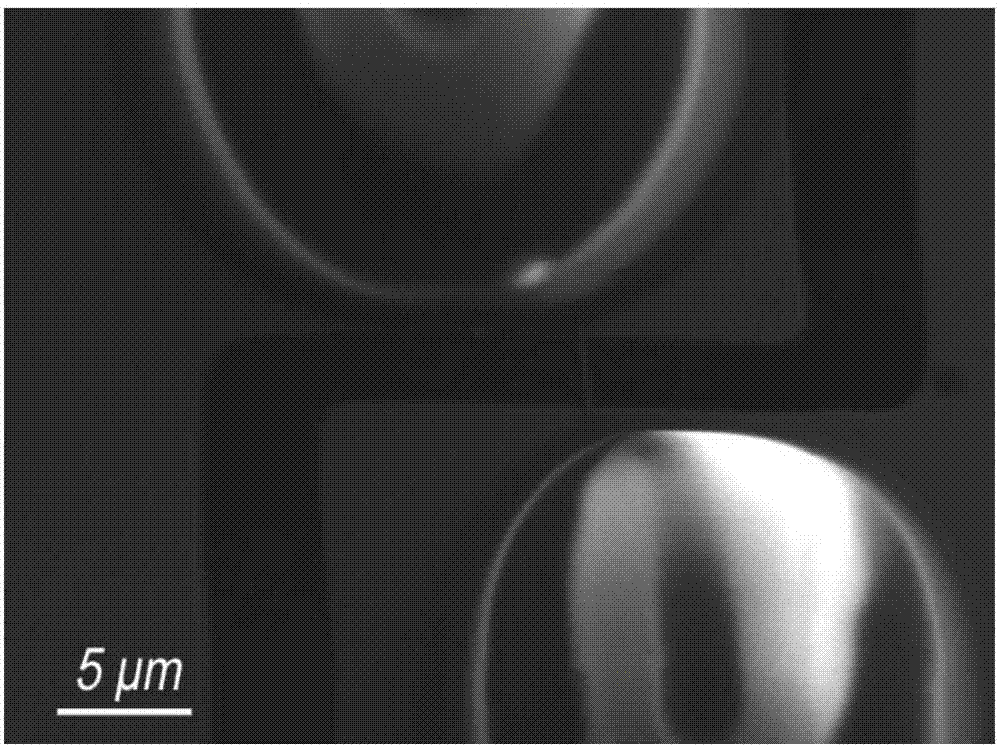

[0037] The sample is a Beta-type SiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com