Composite graphite anode material for lithium-ion battery and preparation method of composite graphite cathode material

A lithium-ion battery and composite graphite technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of small specific surface area, easy to cause pollution, and increased specific surface area of materials, and achieve simple processing procedures and low synthesis costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

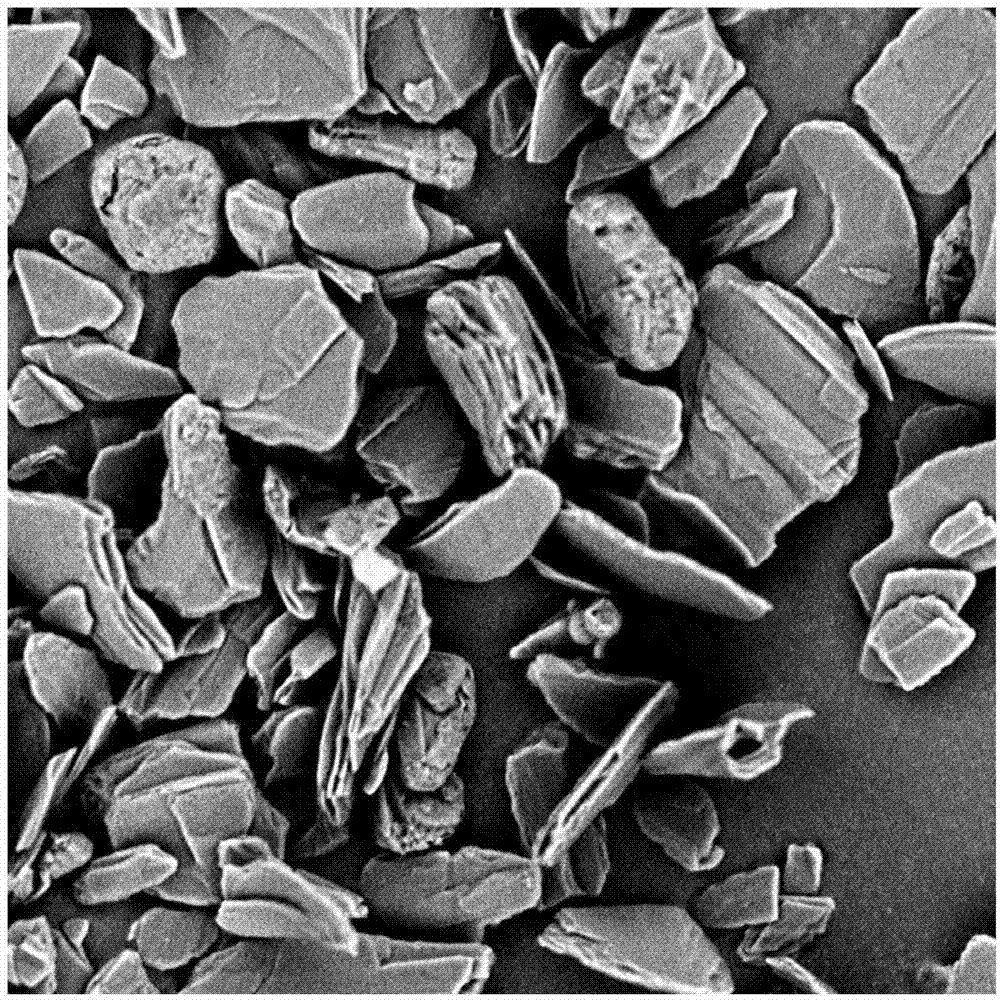

Image

Examples

Embodiment 1

[0026] A composite graphite negative electrode material for a lithium ion battery, comprising an inner core and a shell, the inner core is artificial graphite formed after coke graphitization and uncoated natural graphite, and the shell is the volatile matter in the coke during the graphitization process Formed carbon layer, the preparation steps of the lithium electronic battery composite graphite negative electrode material are as follows:

[0027] 1) Take the needle coke and petroleum coke according to the mass ratio of 0.68:1, and then crush, shape and classify them respectively; <0.3%, sulfur content <0.5%, the average particle size D50 of the needle coke and petroleum coke is 10-40 μm;

[0028] 2) Mixing classified needle coke, petroleum coke and uncoated spherical natural graphite to obtain a mixture; wherein, the added weight of spherical natural graphite is 2.5% of the total amount of needle coke and petroleum coke;

[0029] 3) Send the mixture into the Acheson graph...

Embodiment 2

[0032] A composite graphite negative electrode material for a lithium ion battery, comprising an inner core and a shell, the inner core is artificial graphite formed by graphitization of coke and uncoated natural graphite, and the shell is formed by volatile matter in the process of graphitization of coke Carbon layer, the preparation steps of the lithium electronic battery composite graphite negative electrode material are as follows:

[0033] 1) Take the needle coke and petroleum coke according to the mass ratio of 0.90:1, and then crush, shape and classify them respectively; <0.3%, sulfur content <0.5%, the average particle size D50 of the needle coke and petroleum coke is 10-40 μm;

[0034] 2) Mixing classified needle coke, petroleum coke and uncoated spherical natural graphite to obtain a mixture; wherein, the added weight of spherical natural graphite is 3.5% of the total amount of needle coke and petroleum coke;

[0035] 3) Send the mixture into the Acheson graphitizat...

Embodiment 3

[0038] A composite graphite negative electrode material for a lithium ion battery, comprising an inner core and a shell, the inner core is artificial graphite formed after coke graphitization and uncoated natural graphite, and the shell is formed by volatile matter in the coke graphitization process The carbon layer, the preparation steps of the lithium electronic battery composite graphite negative electrode material are as follows:

[0039] 1) Take the needle coke and petroleum coke according to the mass ratio of 0.3:1, and then crush, shape and classify them respectively; 0.3%, sulfur content <0.5%, the average particle size D50 of the needle coke and petroleum coke is 10-40 μm;

[0040] 2) mixing classified needle coke, petroleum coke and uncoated spherical natural graphite to obtain a mixture; wherein, the added weight of spherical natural graphite is 1% of the total amount of needle coke and petroleum coke;

[0041] 3) Send the mixture into the Acheson graphitization fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com