Method for recovering lithium from waste lithium batteries

A waste lithium battery, lithium recycling technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of high processing cost, only about 50%, lithium recycling, etc., and achieve considerable economic benefits and separation effects good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

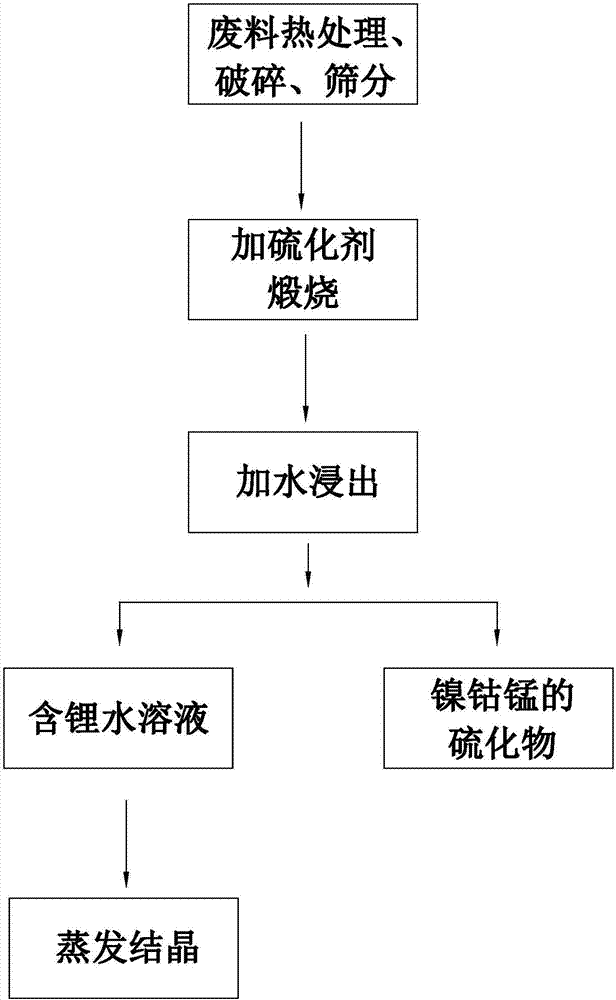

Method used

Image

Examples

Embodiment 1

[0018] A method for reclaiming lithium from waste lithium batteries, comprising the following process steps:

[0019] 1) Heat-treat the positive electrode sheet of lithium cobaltate waste battery or the positive electrode sheet of leftover material to remove the binder, and then obtain the waste lithium cobaltate powder after physical crushing and screening process, and the content of main metal elements is shown in Table 1 below;

[0020] 2) Take 100g of waste lithium cobaltate powder, add 30g of elemental sulfur, mix evenly and place it at 500°C for anaerobic calcination to obtain metal sulfide and lithium compound;

[0021] 3) Cool the calcined material, add 400ml of pure water and stir evenly, so that the lithium compound reacts with water and dissolves in water, while the metal sulfide remains in the solid, and after being fully washed, filter to obtain a filter residue containing metal sulfide and a Lithium aqueous solution, drying the filter residue after washing, its p...

Embodiment 2

[0025] A method for reclaiming lithium from waste lithium batteries, comprising the following process steps:

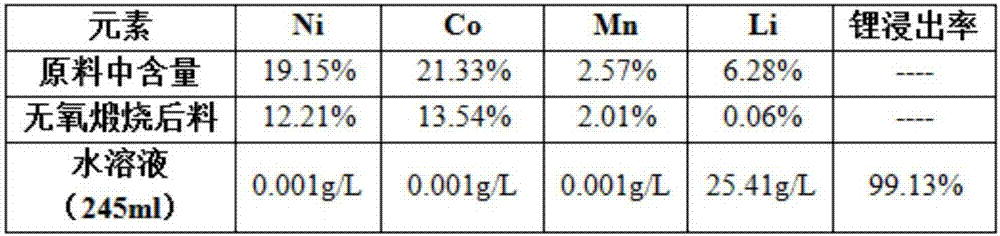

[0026] 1) Heat-treat the positive electrode sheet of nickel-cobalt lithium manganese oxide waste battery (type 111) or scrap positive electrode sheet to remove the binder, and then undergo physical crushing and screening to obtain waste nickel-cobalt lithium manganese oxide powder, in which the main metal elements The content is shown in Table 2 below;

[0027] 2) Take 100g of waste nickel-cobalt-lithium manganese oxide powder, add 100g of sodium sulfide, mix well, place it at 300°C for anaerobic calcination, and obtain metal sulfide and lithium compound;

[0028] 3) Cool the calcined material, add 300ml of pure water and stir evenly, so that the lithium compound reacts with water and dissolves in water, while the metal sulfide remains in the solid, and after being fully washed, filter to obtain the filter residue containing metal sulfide and containing Lithium aqueo...

Embodiment 3

[0032] A method for reclaiming lithium from waste lithium batteries, comprising the following process steps:

[0033] 1) Heat-treat the positive electrode sheet of nickel-cobalt lithium manganese oxide waste battery (high nickel type) or scrap positive electrode sheet to remove the binder, and then obtain waste nickel-cobalt lithium manganese oxide powder after physical crushing and screening process, in which the main metal The element content is shown in Table 3 below;

[0034] 2) Take 100g of waste nickel-cobalt-lithium manganese oxide powder, add 120g of pyrite powder, mix evenly and place it at 700°C for anaerobic calcination to obtain metal sulfide and lithium compound;

[0035] 3) Cool the calcined material, add 250ml of pure water and stir evenly, so that the lithium compound reacts with water and dissolves in water, while the metal sulfide remains in the solid, and after being fully washed, filter to obtain a filter residue containing metal sulfide and a Lithium aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com