Waste gas photolysis treatment device

A treatment device and photolysis technology, applied in gas treatment, separation methods, and separation of dispersed particles, can solve the problems of inability to process long molecular chain organic matter and benzene series, low efficiency of organic waste gas treatment, and low removal rate of organic matter. Achieve long-term stable treatment effect, high waste gas conversion efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

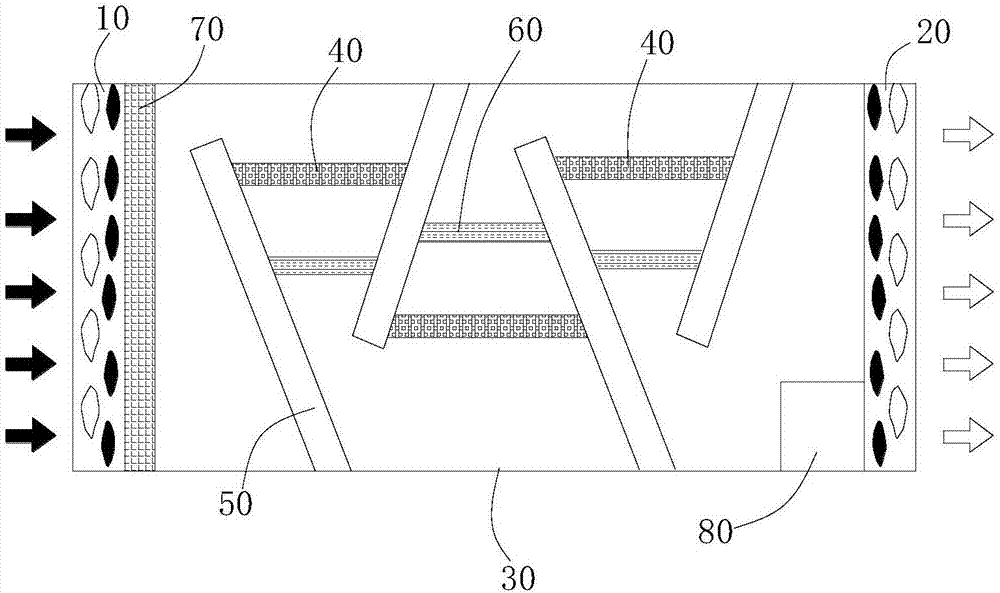

[0018] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

[0019] Such as figure 1 As shown, it is a schematic structural diagram of a waste gas photolysis treatment device in a preferred embodiment of the present invention. The chemical organic substances treated by photolysis in the present invention include benzenes, alkanes, aromatic hydrocarbons, olefins, alcohols, ketones, Aldehydes, esters, etc. At the same time, the invention has deodorizing and sterilizing functions, and can be used for biological odor and bacterial disinfection treatment. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com