Gel propellant adopted as aerospace fuel, preparation method and uses thereof

A gel propellant, aerospace technology, used in non-explosive fillers/gelling agents/thickeners, offensive equipment, compressed gas generation, etc. Leakage and other problems, to achieve the effect of improving rheological properties and high instantaneous recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Raw material 2,4-(3,4-dichlorobenzylidene)-D-methyl gluconate (II) used in the present invention is made by following method:

[0037]

[0038] Add 215.8 g of 50 wt % D-gluconic acid aqueous solution (0.55 mol of D-gluconic acid), 100 mL of methanol, and 200 mL of concentrated hydrochloric acid into a 1L four-necked flask equipped with mechanical stirring and a thermometer at room temperature, and stir at 200 rpm. Add a methanol solution of 3,4-dichlorobenzaldehyde (dissolve 87.5g (0.50mol) of 3,4-dichlorobenzaldehyde in 300mL of methanol), and the system becomes viscous after 4 hours of reaction. Minute speed stirring reaction for 20h, after the reaction is completed, add 100mL water to the system, stir for 2h and then filter with suction, wash the filter cake with a large amount of water until the pH is 6-7, then wash twice with 200mL of hot dichloromethane, and drain to obtain Product II, dried to 140g. The yield was 76%, and the melting point was 188.6-189.2°C. ...

Embodiment 2

[0040] The preparation method of acetal substituted glucamide, comprises the steps:

[0041] With 4-dimethylaminopyridine (DMAP) as catalyst, 2,4-(3,4-dichlorobenzylidene)-D-gluconic acid methyl ester (II) and aliphatic monoamine (C n h 2n+1 NH 2 , n=5, 6, 7, 8, 9, 10, 12, 14, 16 or 18) are raw materials, pyridine is the glucamide molecule (I) that acetal is substituted under the condition of solvent, and reaction equation is as follows .

[0042]

[0043] Said n=5, 6, 7, 8, 9, 10, 12, 14, 16 or 18.

[0044] Embodiment 1, embodiment 2 refer to Chinese patent CN104478847A

Embodiment 3

[0046] A preparation method of a gel propellant as aerospace fuel, comprising the following steps: adding acetal-substituted glucosamide to JP-10 so that the content of acetal-substituted glucosamide is 20 mg / mL, and heating to 165 ℃, stop stirring, cool to room temperature, see gel figure 1 .

[0047] Acetal substituted glucamide as shown in formula (I):

[0048]

[0049] Where n=8, it is named G8 (the products prepared in the following examples are all named according to this, such as n=5, named G5, etc.).

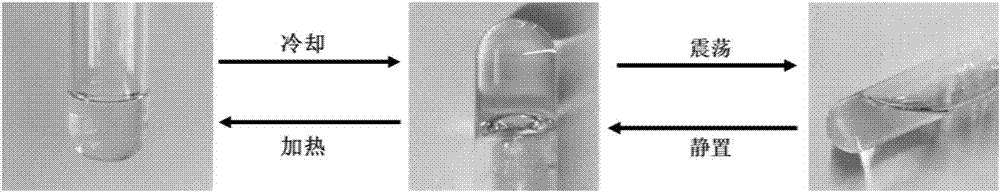

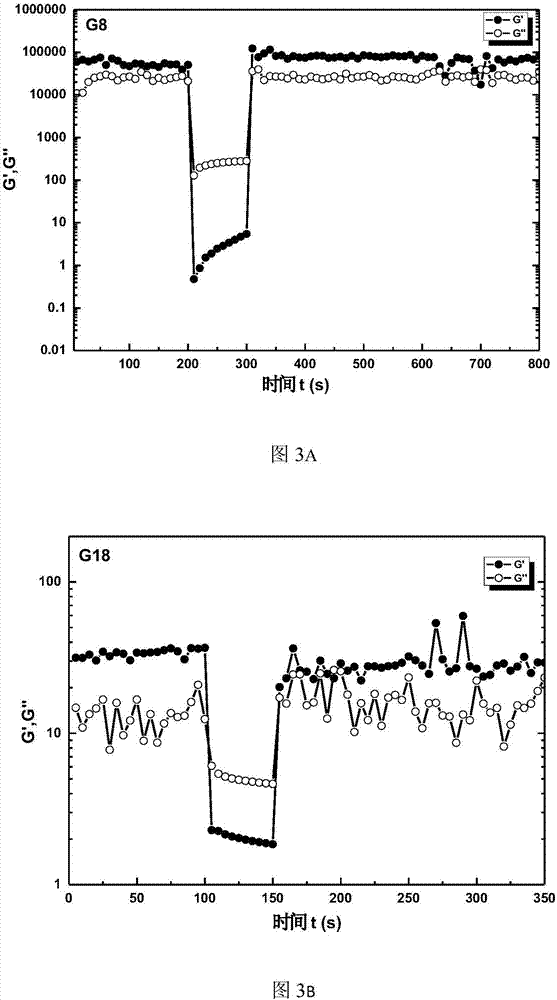

[0050] The gel is thermally reversible, that is, it is completely dissolved after heating, and then cooled to room temperature to form a transparent gel. This process can be repeated many times; the gel is thixotropic, that is, it can Destroy the gel into a solution, and partially or completely recover to a gel after standing for a period of time (see figure 2 ).

[0051] The acetal-substituted glucamide with n=18 is substituted for the acetal-substituted glucami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com