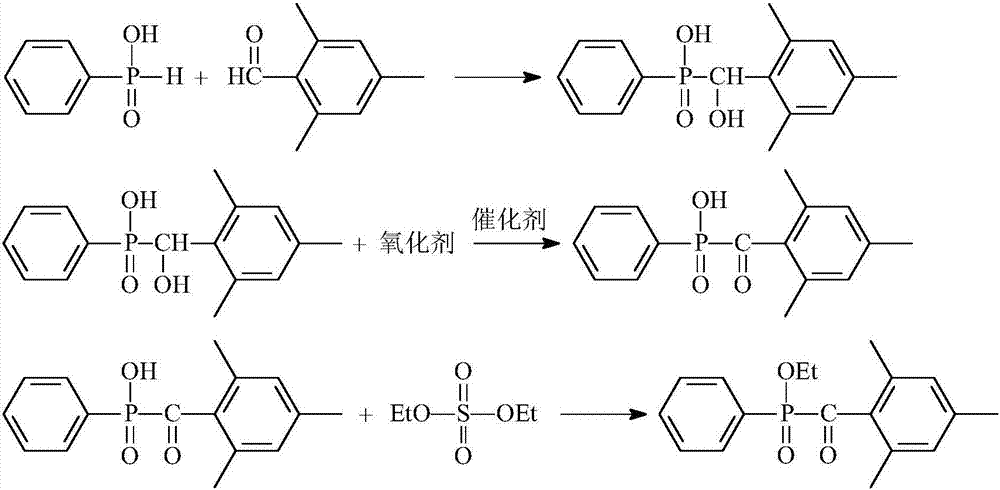

Preparation method for high-purity ethyl (2,4,6-trimethylbenzoyl)phenylphosphinate

A technology of ethyl trimethylbenzoyl and phenylphosphinate, which is applied in the field of preparation of high-purity ethyl phenylphosphinate, can solve the problem of low purity, and achieve the effect of ensuring product purity and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 0.1mol of phenylphosphinic acid and 100mL of toluene into the reaction kettle, control the temperature at 100-120°C and add 0.11mol of 2,4,6-trimethylbenzaldehyde dropwise, after the addition is completed, at this temperature (100-120°C) The reaction was carried out under heat preservation for 2 hours to prepare the intermediate. Cool down to room temperature, add a small amount of hydrochloric acid to adjust the pH to 4-6, add 0.13 g of vanadium diacetylacetonate as a catalyst, add 0.12 mol of tert-butanol peroxide dropwise at 5-10 °C, and keep warm at 5-10 °C after the addition is completed. It was observed by TLC that all the intermediates were completely reacted, and a reaction mixture 1 was obtained. Add 100mL of water to the reaction mixture 1, adjust the pH to neutral with saturated aqueous sodium bicarbonate solution, separate the aqueous layer, wash it twice with water, reduce the excess oxidant with an appropriate amount of aqueous sodium sulfite solution,...

Embodiment 2

[0022] Add 0.1mol of phenylphosphinic acid and 100mL of chlorobenzene into the reaction kettle, control the temperature at 100-120°C, add 0.11mol of 2,4,6-trimethylbenzaldehyde dropwise, and keep the temperature at 100-120°C for reaction After 2 hours, the intermediate was prepared. Cool down to room temperature, add a small amount of hydrochloric acid to adjust the pH to 4-6, add 0.13 g of vanadium diacetylacetonate as a catalyst, add 0.15 mol of tert-butanol peroxide dropwise at 5-10 °C, and keep warm at 5-10 °C after the addition is completed. It was observed by TLC that all the intermediates were completely reacted, and a reaction mixture 1 was obtained. Add 100mL of water to the reaction mixture 1, adjust the pH to neutral with saturated aqueous sodium bicarbonate solution, separate the aqueous layer, wash it twice with water, reduce the excess oxidant with an appropriate amount of aqueous sodium sulfite solution, separate the organic layer, and wash it twice with water. ...

Embodiment 3

[0024] Add 0.1mol of phenylphosphinic acid and 100mL of chlorobenzene into the reaction kettle, control the temperature at 100-120°C, add 0.11mol of 2,4,6-trimethylbenzaldehyde dropwise, and keep the temperature at 100-120°C for reaction After 2 hours, the intermediate was prepared. Then cool down to room temperature, add a small amount of hydrochloric acid to adjust the pH to 4-6, add catalyst V 2 o 5 0.1 g, 0.15 mol of tert-butanol peroxide was added dropwise under control of 5-10°C, and kept warm at 5-10°C after the addition was completed. It was observed by TLC that all intermediates were completely reacted, and reaction mixture 1 was obtained. Add 100mL of water to the reaction mixture 1, adjust the pH to neutral with saturated aqueous sodium bicarbonate solution, separate the aqueous layer, wash it twice with water, reduce the excess oxidant with an appropriate amount of aqueous sodium sulfite solution, separate the organic layer, and wash it twice with water. Once ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com