Preparation method of organic silicon pouring sealant for LED (light emitting diode) encapsulation

A technology of silicone potting glue and LED packaging, which is applied in the direction of adhesives, adhesive additives, electrical components, etc., can solve the problems of not having good fluidity and excellent adhesion, and achieve reduced migration resistance and good compatibility , Improve the effect of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

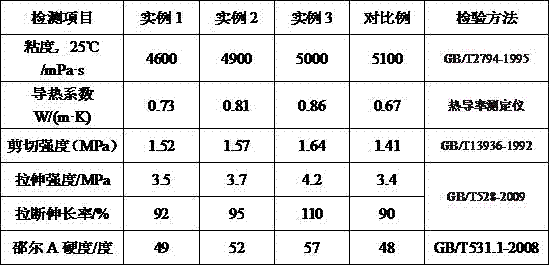

Examples

example 1

[0022] Take 100g of vinyl silicone oil, 350g of silicon micropowder, 10g of spherical alumina and 5g of silane coupling agent A-171 into a kneader, heat to 120°C and mix for 1 hour, then heat to 160°C for 1 hour, cool to room temperature and discharge To obtain the base material, take 360g of hydroxyl silicone oil, 200g of silane coupling agent KH-560, and 70g of tetramethyltetravinylcyclotetrasiloxane into a reaction kettle, heat to 50°C, and stir at 200r / min for 20min, Then add 0.15g of dibutyltin dilaurate, continue to stir and heat to 60°C, keep warm for 3 hours, then vacuumize to 100Pa, continue for 30min, keep warm for 1h, cool to room temperature, and discharge to obtain a tackifier, in parts by weight In total, take 200 parts of base material, 50 parts of vinyl silicone oil, 20 parts of tackifier, and 0.1 part of platinum catalyst in a kneader and mix them evenly, then grind and disperse them with a three-roller mill for 20 minutes to obtain component A. In terms of pa...

example 2

[0024] Take 110g of vinyl silicone oil, 385g of silicon micropowder, 30g of spherical alumina and 5g of silane coupling agent A-171 into the kneader, heat to 140°C and mix for 1 hour, then heat to 170°C for 1 hour, cool to room temperature and discharge To obtain the base material, take 380g of hydroxyl silicone oil, 220g of silane coupling agent KH-560, and 75g of tetramethyltetravinylcyclotetrasiloxane into a reactor, heat to 53°C, and stir at 250r / min for 25min, Then add 0.18g of dibutyltin dilaurate, continue to stir and heat to 63°C, vacuumize to 550Pa after heat preservation for 3 hours, continue for 35 minutes, heat heat for 1 hour, cool to room temperature, and discharge to obtain a tackifier, in parts by weight In total, take 225 parts of base material, 55 parts of vinyl silicone oil, 25 parts of tackifier, and 0.2 parts of platinum catalyst, put them into a kneader and mix them evenly, then grind and disperse them with a three-roller mill for 25 minutes to obtain comp...

example 3

[0026]Take 120g of vinyl silicone oil, 420g of silicon micropowder, 50g of spherical alumina and 6g of silane coupling agent A-171 into the kneader, heat to 160°C and mix for 2 hours, then heat to 180°C for 2 hours, cool to room temperature and discharge To obtain the base material, take 400g of hydroxyl silicone oil, 240g of silane coupling agent KH-560, and 80g of tetramethyltetravinylcyclotetrasiloxane into a reaction kettle, heat to 55°C, and stir at 300r / min for 30min, Then add 0.20g of dibutyltin dilaurate, continue to stir and heat to 65°C, keep warm for 4 hours, then vacuumize to 1000Pa, continue for 40 minutes, keep warm for 2 hours, cool to room temperature, and discharge to obtain a tackifier, in parts by weight In total, take 250 parts of base material, 60 parts of vinyl silicone oil, 30 parts of tackifier, and 0.3 parts of platinum catalyst in a kneader and mix them evenly, then grind and disperse them with a three-roller mill for 30 minutes to obtain component A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com