Two-section type catalyst for diesel vehicle exhaust treatment and preparation method of catalyst

A tail gas treatment and catalyst technology, applied in physical/chemical process catalysts, gas treatment, molecular sieve catalysts, etc., can solve the problems of unable to eliminate particulate matter, poisoning can withstand space velocity, and reduced catalytic activity, achieving excellent N2 selectivity, urea The effect of decomposing and eliminating escaped NH3 and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a method for preparing the two-stage catalyst described in the above technical solution, comprising the following steps:

[0057] a) Hydrothermal reaction of cerium source, X' source and triethylamine in the first solvent to obtain CeO 2 -X nanoparticles; the X' source is selected from a copper source, an iron source or a manganese source;

[0058] b) Co-precipitate M' source, cerium source and ammonia water in the second solvent to obtain M@CeO 2 Core-shell nanoparticle; The M' source is selected from a rhodium source, a platinum source or a palladium source;

[0059] c) the CeO obtained in step a) 2 -X nanoparticles and M@CeO obtained from step b) 2 Nanoparticles with core-shell structure are respectively loaded with molecular sieves to obtain Catalyst A and Catalyst B respectively;

[0060] d) Catalyst A is arranged at the intake end, and catalyst B is arranged at the outlet end to obtain a two-stage catalyst for diesel vehicle...

Embodiment 1

[0078] (1) Preparation of CeO 2 -Fe 2 o 3 Nanoparticles:

[0079] Weigh 5.4g of polyvinylpyrrolidone (PVP-K30) and dissolve it in 360mL of absolute ethanol; after the PVP is completely dissolved, add 0.7422g of cerium nitrate and 0.0218g of ferric nitrate into the solution, stir until completely dissolved, then add 1.82g of triethylamine dropwise , stirred for another 10 minutes, then transferred to the reactor, and reacted hydrothermally at 180° C. for 24 hours. After the reaction, the solution was taken out to a constant volume (0.0008 g / mL) for use.

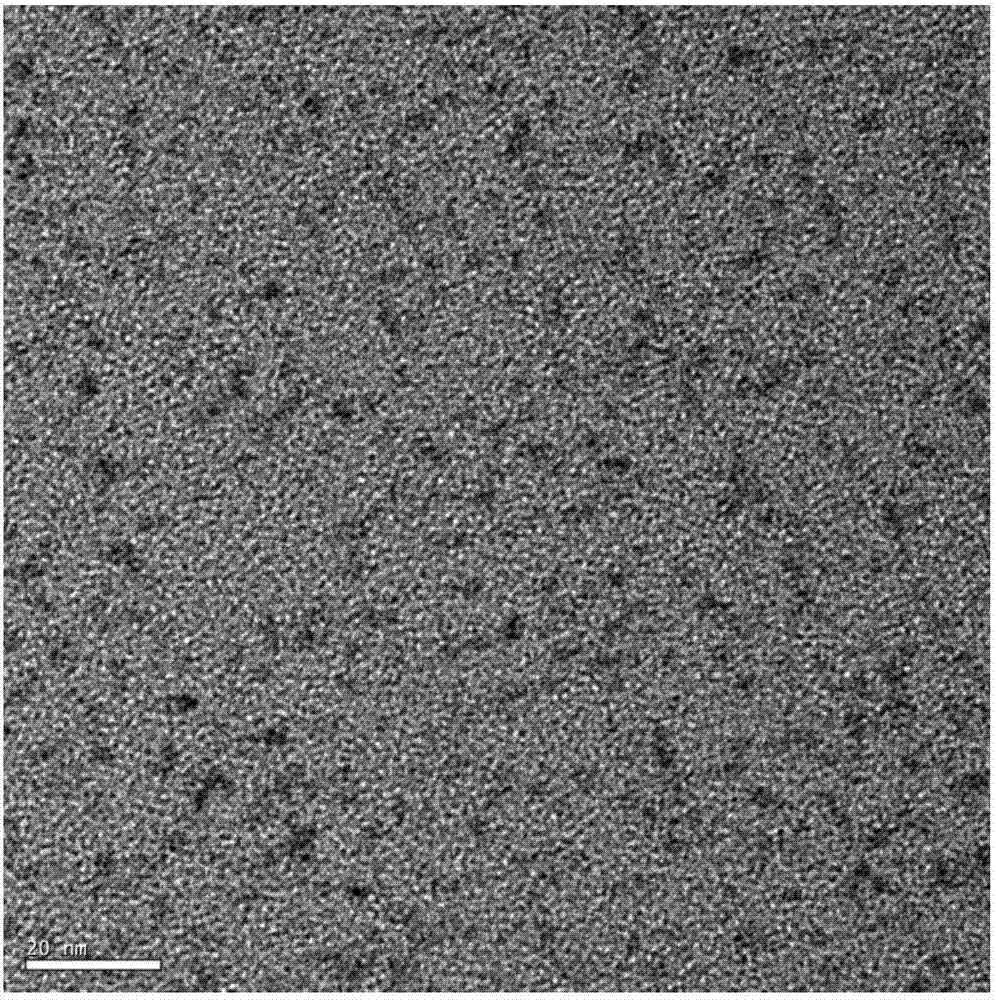

[0080] The CeO 2 -Fe 2 o 3 TEM images of the nanoparticles as figure 1 shown by figure 1 It can be seen that CeO 2 -Fe 2 o 3 The average particle diameter of the nanoparticles is 3nm-5nm.

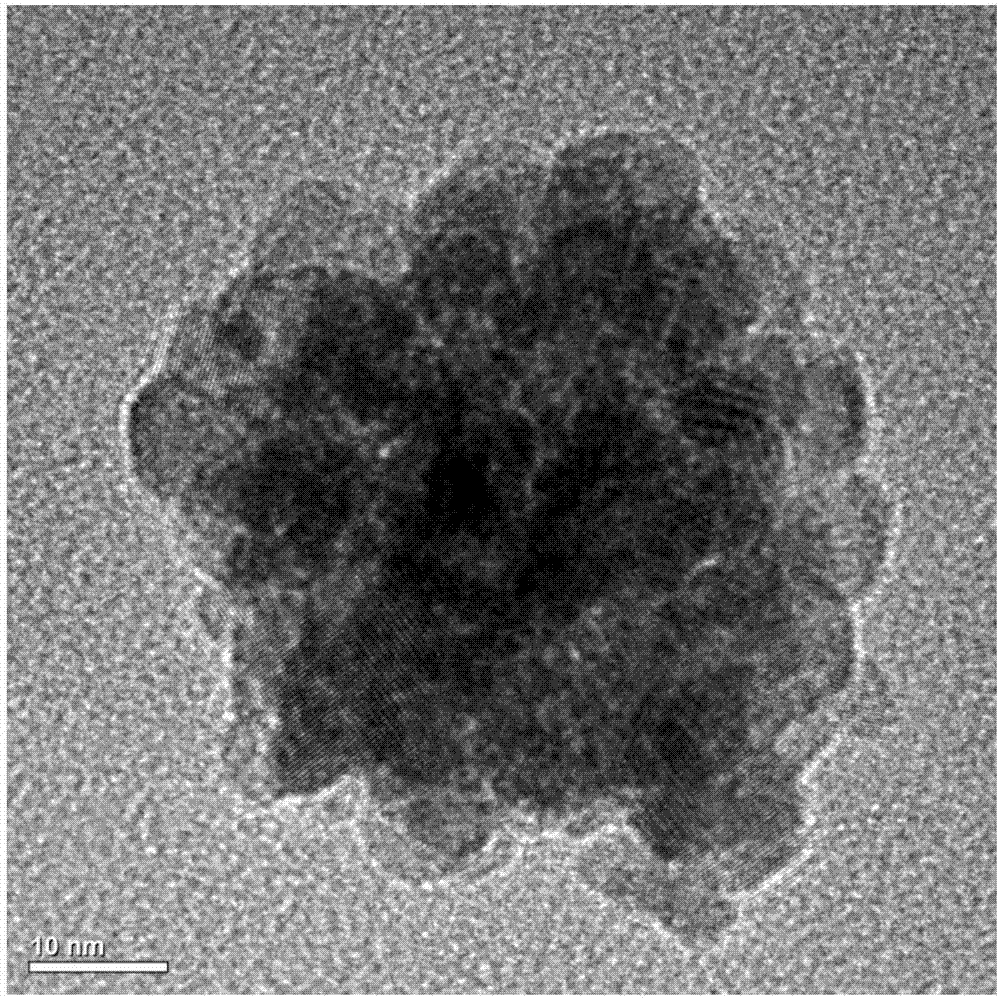

[0081] (2) Preparation of Rh@CeO 2 Core-shell nanoparticles:

[0082] Add 7.5mg of potassium bromide to a beaker with 20mL of deionized water, stir and dissolve in a water bath at 60°C, then add 0.417mL of 0.03M rhodium nitrate...

Embodiment 2

[0090] (1) Preparation of CeO 2 -Fe 2 o 3 Nanoparticles:

[0091] Weigh 5.4g of polyvinylpyrrolidone (PVP-K30) and dissolve it in 360mL of absolute ethanol; after the PVP is completely dissolved, add 0.4661g of cerium nitrate and 0.0186g of ferric nitrate into the solution, stir until completely dissolved, and then dropwise add 1.22g of triethylamine , stirred for another 10 minutes, then transferred to the reactor, and reacted hydrothermally at 180° C. for 24 hours. After the reaction, the solution was taken out to a constant volume (0.0008 g / mL) for use.

[0092] (2) Preparation of Rh@CeO 2 Nanoparticles with core-shell structure: the same as in Example 1.

[0093] (3) Preparation of CeO 2 -Fe 2 o 3 / ZSM-5: Same as Example 1.

[0094] (4) Preparation of Rh@CeO 2 / ZSM-5: Same as Example 1.

[0095] (5) 25mg catalyst A is arranged at the inlet end of the tubular fixed bed reactor, and 25mg catalyst B is arranged at the gas outlet end of the tubular fixed bed reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com