Preparing method of AuSn20 brazing filler metal for improving braze performance

A performance and brazing technology, which is applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve problems such as uneven composition of alloy solder, high brittleness of alloy solder, and complex process, etc., to improve brazing Welding performance, lower vacuum brazing temperature, uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

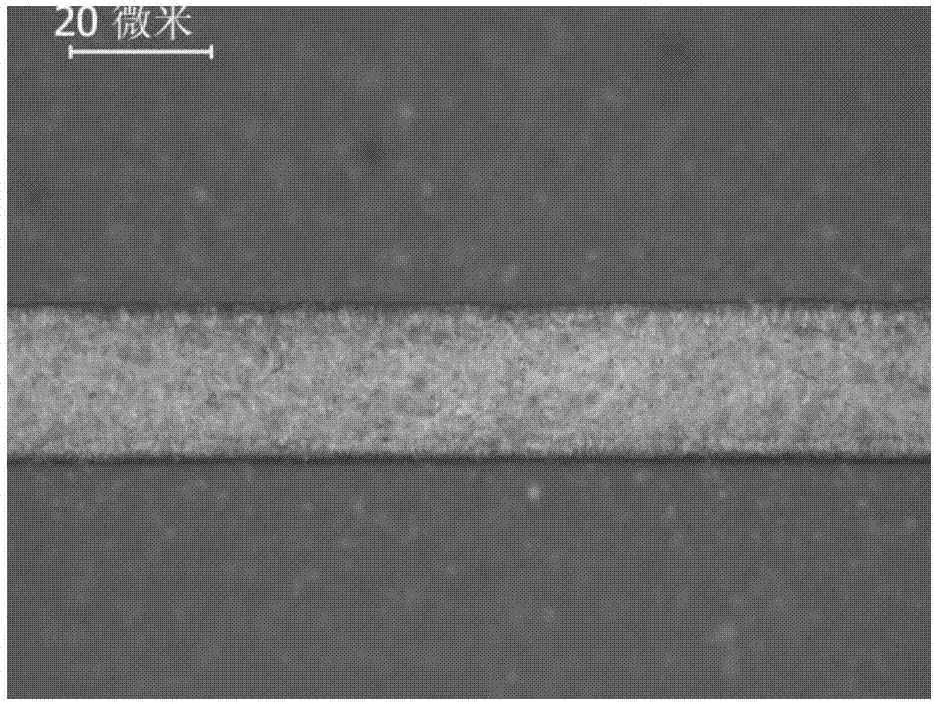

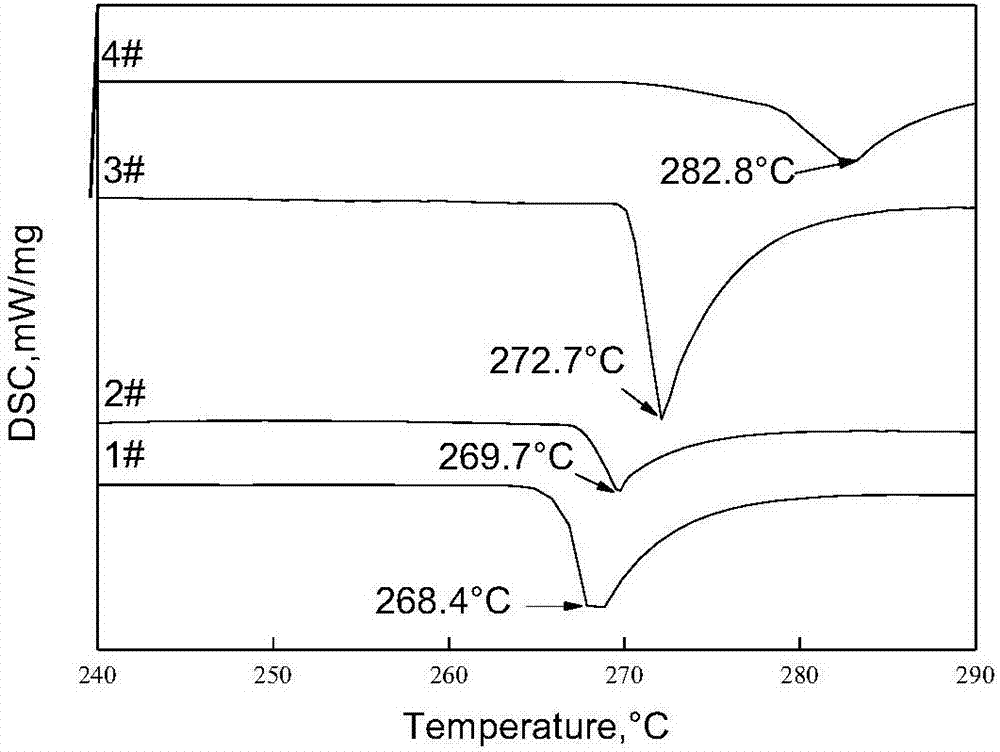

Embodiment 1

[0018] Prepare the gold-tin raw material, the mass percentage of tin and gold is 1:4, put the weighed gold-tin raw material into a graphite crucible, heat it in a vacuum induction furnace, take it out after the melt is cooled, and cast the obtained gold-tin alloy The ingot was put into the graphite crucible again, and heated in a vacuum induction furnace. After repeating this three times, the gold-tin alloy ingot was obtained. Smash the massive gold-tin alloy ingot and put it into a quartz tube with a rectangular opening at the bottom. The distance between the bottom of the quartz tube and the copper roller is 2mm. Turn on the single roller stripping device, adjust the roller speed to 3000r / min, and then adjust the nitrogen gas flow pressure to 0.2Mpa. The gold-tin alloy ingot in the quartz tube is heated by induction heating. After heating for 4 minutes, it is directly sprayed onto the copper roller and moves with the roller surface to finally obtain the gold-tin alloy foil w...

Embodiment 2

[0020] Prepare the gold-tin alloy raw material, weigh it according to the mass percentage of gold and tin at 4:1, put the weighed gold-tin raw material into a graphite crucible, heat it in a vacuum induction furnace, take it out after the melt is cooled, and put the obtained gold-tin The alloy ingot was put into the graphite crucible again, and heated in a vacuum induction furnace. After repeating this for three times, the gold-tin alloy ingot was obtained. Smash the massive gold-tin alloy ingot and put it into a quartz tube with a rectangular opening at the bottom. The distance between the bottom of the quartz tube and the copper roller is 4mm. Turn on the single-roller stripping device, adjust the roll speed to 2800r / min, and then adjust the nitrogen gas flow pressure to 0.3Mpa. The gold-tin alloy ingot in the quartz tube is heated by induction heating. After heating for 5 minutes, it is directly sprayed onto the copper roller and moves with the roller surface, and finally t...

Embodiment 3

[0022] Prepare the gold-tin alloy raw material, weigh it according to the mass percentage of gold and tin at 4:1, put the weighed gold-tin raw material into a graphite crucible, heat it in a vacuum induction furnace, take it out after the melt is cooled, and put the obtained gold-tin The alloy ingot was put into the graphite crucible again, and heated in a vacuum induction furnace. After repeating this for three times, the gold-tin alloy ingot was obtained. Smash the massive gold-tin alloy ingot and put it into a quartz tube with a rectangular opening at the bottom. The distance between the bottom of the quartz tube and the copper roller is 5mm. Turn on the single-roller stripping device, adjust the roll speed to 2000r / min, and then adjust the nitrogen gas flow pressure to 0.3Mpa. The gold-tin alloy ingot in the quartz tube is heated by induction heating. After heating for 4 minutes, it is directly sprayed onto the copper roller and moves with the roller surface, and finally t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com