Imitation stone matte rock flake paint for building exterior wall coating and preparation method thereof

A technology of architectural exterior wall and rock flake paint, applied in the field of decorative paint, which can solve the problems of complicated preparation process, strong mirror effect, and accelerated paint aging rate, and achieve the effect of simple construction process, obvious construction effect and superior product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

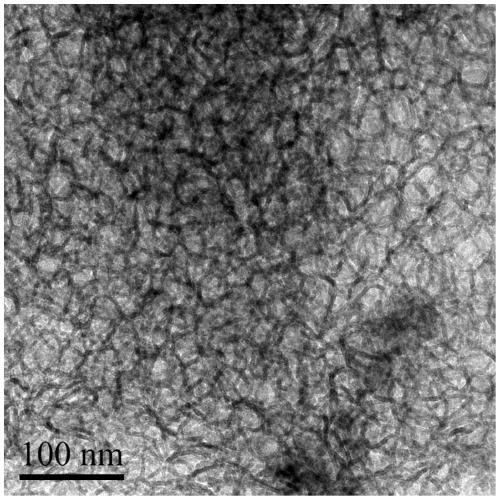

[0042] First, under the acidic condition of pH = 2, add a mixture with a mass ratio of triblock copolymer P123:cyclohexane:tetraethyl silicate at a mass ratio of 1:0.5:2.1, and the temperature in the reactor is 100 The three-dimensional porous nano-SiO can be prepared by reacting at ℃ for 24h, filtering, washing, drying and calcination at 550℃. 2 ,Such as figure 1 shown. Secondly, by weight, add 24.8% of tap water, 0.1% of wetting agent, 0.3% of defoamer, 0.1% of multifunctional auxiliary agent, 2% of film-forming auxiliary agent in the agitator, and the stirring speed is 800 rpm , and then add emulsion 36%, three-dimensional porous nano-SiO 2 5%, natural rock flakes of different sizes and specifications 30%, add thickening agent 1.5%, bactericidal preservative 0.2% after stirring evenly, and after stirring for 30 minutes, stone-like matte rock flake paint can be obtained, and can be packaged after passing the inspection.

Embodiment 2

[0044] First, under the acidic condition of pH = 2, add a mixture with a mass ratio of triblock copolymer P123:cyclohexane:tetraethyl silicate at a mass ratio of 1:1:2.1, and the temperature in the reactor is 120 The three-dimensional porous nano-SiO can be prepared by reacting at ℃ for 24 hours, filtering, washing, drying and calcination at 650℃. 2 . Secondly, by weight, add 29.8% of tap water, 0.1% of wetting agent, 0.3% of defoamer, 0.1% of multifunctional auxiliary agent, 2% of film-forming auxiliary agent in the agitator, and the stirring speed is 800 rpm , and then add emulsion 36%, three-dimensional porous nano-SiO 2 5%, natural rock flakes of different sizes and specifications 25%, add thickening agent 1.5%, bactericidal preservative 0.2% after stirring evenly, and after stirring for 30 minutes, stone-like matte rock flake paint can be obtained, and can be packaged after passing the inspection.

Embodiment 3

[0046] First, under the acidic condition of pH = 2, add a mixture with a mass ratio of triblock copolymer P123:cyclohexane:tetraethyl silicate at a mass ratio of 1:0.5:2.1, and the temperature in the reactor is 100 The three-dimensional porous nano-SiO can be prepared by reacting at ℃ for 24h, filtering, washing, drying and calcination at 550℃. 2 . Secondly, by weight, add 30% of tap water, 0.1% of wetting agent, 0.4% of defoamer, 0.2% of multifunctional auxiliary agent, 6% of film-forming auxiliary agent in the mixer, and the stirring speed is 800 rpm , and then add 30% emulsion, three-dimensional porous nano-SiO 2 8%, natural rock flakes of different sizes and specifications 23.5%, add thickening agent 1.5%, bactericidal preservative 0.3% after stirring evenly, and after stirring for 30 minutes, stone-like matte rock flake paint can be obtained, and can be packaged after passing the inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com