Method for producing food calling agent from fish soluble pulp

A technology of fish soluble slurry and food attractant, applied in the direction of bacteria used in food preparation, application, food science, etc., can solve the problems of ineffective enzymatic hydrolysis of protein, inconvenient storage and transportation, unsuitable for digestion and absorption, etc., to improve feed Conversion rate, improvement of resource utilization rate and added value, and the effect of reducing environmental harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

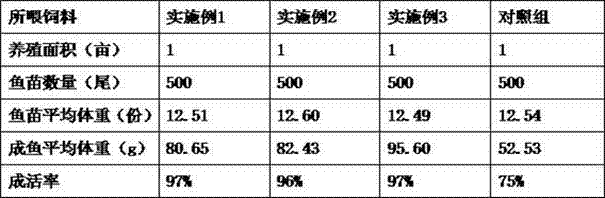

Examples

Embodiment 1

[0020] A method for producing an attractant by utilizing fish-dissolved pulp, specifically comprising the following steps:

[0021] 1) Add 0.2 parts of lipase to 500 parts of sterilized fish lysate, stir and ventilate at 35°C, let it react for 1.5 hours, complete lipolysis and fatty acid oxidation, and obtain defatted fish lysate, Lipase hydrolysis and fatty acid oxidation can effectively prevent the metabolites of fatty acids from causing acidosis in fish; 2) Test the pH value of the fish soluble pulp. In an alkaline environment, add 1.2 parts of trypsin, 1.2 parts of elastase and 1.2 parts of Bromelain; in an acidic environment, add 2.5 parts of pepsin, 0.6 parts of papain and 0.6 parts of bromelain to the container, and react for 2 hours under a vacuum of 0.02 MPa to reduce the proportion of amino acid oxidation after hydrolysis , the reaction temperature should be controlled between 35°C to maximize the activity of the enzyme. The products of protein enzymolysis are oligop...

Embodiment 2

[0023] A method for producing an attractant by utilizing fish-dissolved pulp, specifically comprising the following steps:

[0024] 1) Sterilization: Pour 500 parts of fish soluble slurry into a sealed stainless steel container, and cook for 30 minutes at a pressure of 80 MPa and a temperature of 140°C. The basic principle of the sterilization is the lethal effect of high temperature and high pressure on microorganisms, mainly through It is achieved by destroying the cell membrane, inhibiting the activity of enzymes and affecting the replication of genetic material such as DNA;

[0025] 2) Degreasing: add 0.25% lipase to the fish soluble slurry obtained in step 1, stir and ventilate at 36°C, let it react for 1.5 hours, complete lipolysis and fatty acid oxidation, and obtain defatted fish soluble slurry, fat Enzymatic hydrolysis and fatty acid oxidation can effectively prevent the metabolites of fatty acids from causing acidosis in fish;

[0026] 3) Enzymatic hydrolysis: test ...

Embodiment 3

[0031] A method for producing an attractant by utilizing fish-dissolved pulp, specifically comprising the following steps:

[0032] Sterilization: Pour 500 parts of fish soluble slurry into a sealed stainless steel container and cook for 20 minutes at a pressure of 50 MPa and a temperature of 120°C. The basic principle of the sterilization is the lethal effect of high temperature and high pressure on microorganisms, mainly through the destruction of cell membranes Enzyme activity and affect the replication of genetic material such as DNA;

[0033]Degreasing: add 0.2 parts of lipase to the fish soluble slurry obtained after the sterilization step, stir and ventilate at 37°C, let it react for 1.5 hours, complete lipolysis and fatty acid oxidation, and obtain defatted fish soluble slurry, Lipase hydrolysis and fatty acid oxidation can effectively prevent fatty acid metabolites from causing acidosis in fish;

[0034] Enzymolysis: Test the pH value of the fish soluble slurry obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com