Compound filter pad, and preparation method and application thereof

A composite, filter pad technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of lack of data support for fat volume retention, no in vivo experimental data, low oil absorption and water removal efficiency, etc., and achieve good results. Biocompatibility and fluid-conducting ability, reducing reverse osmosis, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Firstly, the polypropylene particles are spunbonded-meltblown, and the solution is prepared with sulfonate surfactants, and then the polypropylene particles are soaked at 50-60°C to be hydrophilically modified for 20-30 minutes, and then dried to obtain polypropylene SMS Non-woven fabric surface layer, the pore size is below 16μm;

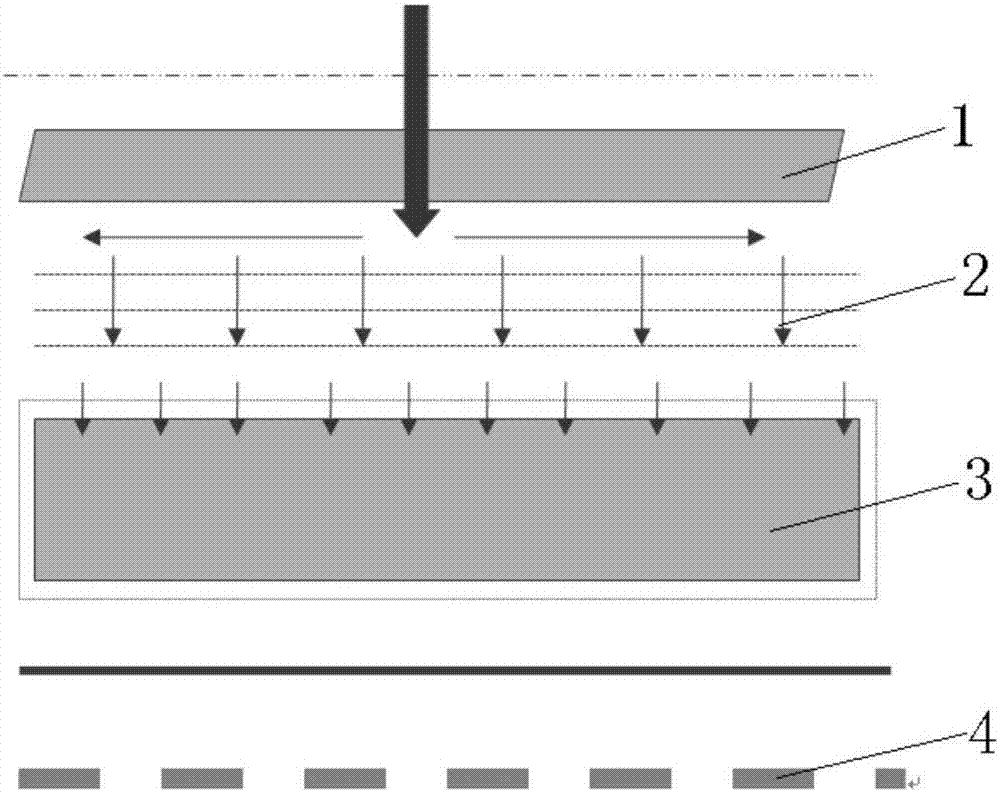

[0045] 2) Then the polypropylene SMS non-woven fabric surface layer 1, the hot air guide layer 2 (composed of synthetic fibers and cellulose), the absorbent fiber layer 3 (SAF super absorbent fiber), and the back adhesive layer 4 (polypropylene fiber material) Arrange from top to bottom and then squeeze and compound to form a composite filter pad. See attached for specific structure figure 1 .

Embodiment 2

[0047] 1) First, the polypropylene particles are spun-bonded-melt-blown, and the solution is prepared with sodium bis(2-ethylhexyl) succinate sulfonate, and then the polypropylene particles are soaked at 50-60°C for hydrophilic modification 20- 30min, dry to obtain polypropylene SMS non-woven fabric surface layer, the pore diameter of which is below 15.5μm;

[0048] 2) Then the polypropylene SMS non-woven fabric surface layer, hot air guide layer (composed of synthetic fibers and cellulose), water-absorbent fiber layer (SAF super absorbent fiber), and back glue bottom layer (polypropylene fiber material) from top to bottom After arranging, it is extruded and compounded at 245-320℃, and shaped at 65℃ to obtain a composite filter pad.

Embodiment 3

[0050] 1) First, the polypropylene particles are spun-bonded-melt-blown, and the solution is prepared with sodium bis(2-ethylhexyl) succinate sulfonate, and then the polypropylene particles are soaked at 50-60°C for hydrophilic modification 20- 30min, dry to obtain a polypropylene SMS non-woven surface layer with a pore size of 15μm and an areal density of 11g / m 2 Below, the thickness is below 95μm, and the air permeability is below 14m / s;

[0051] 2) Then the polypropylene SMS non-woven fabric surface layer, hot air guide layer (composed of synthetic fibers and cellulose), water-absorbent fiber layer (SAF super absorbent fiber), and back glue bottom layer (polypropylene fiber material) from top to bottom After arranging, it is extruded and compounded at 250°C and shaped at 80°C to obtain a composite filter pad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com