Barrel-shaped non-running-on spring and mixed density medium side-placed type vibromill

A technology of mixed density and vibration grinding, applied in grain processing and other directions, can solve the problems of high noise and low efficiency, and achieve the effects of high energy consumption, reduced energy consumption and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

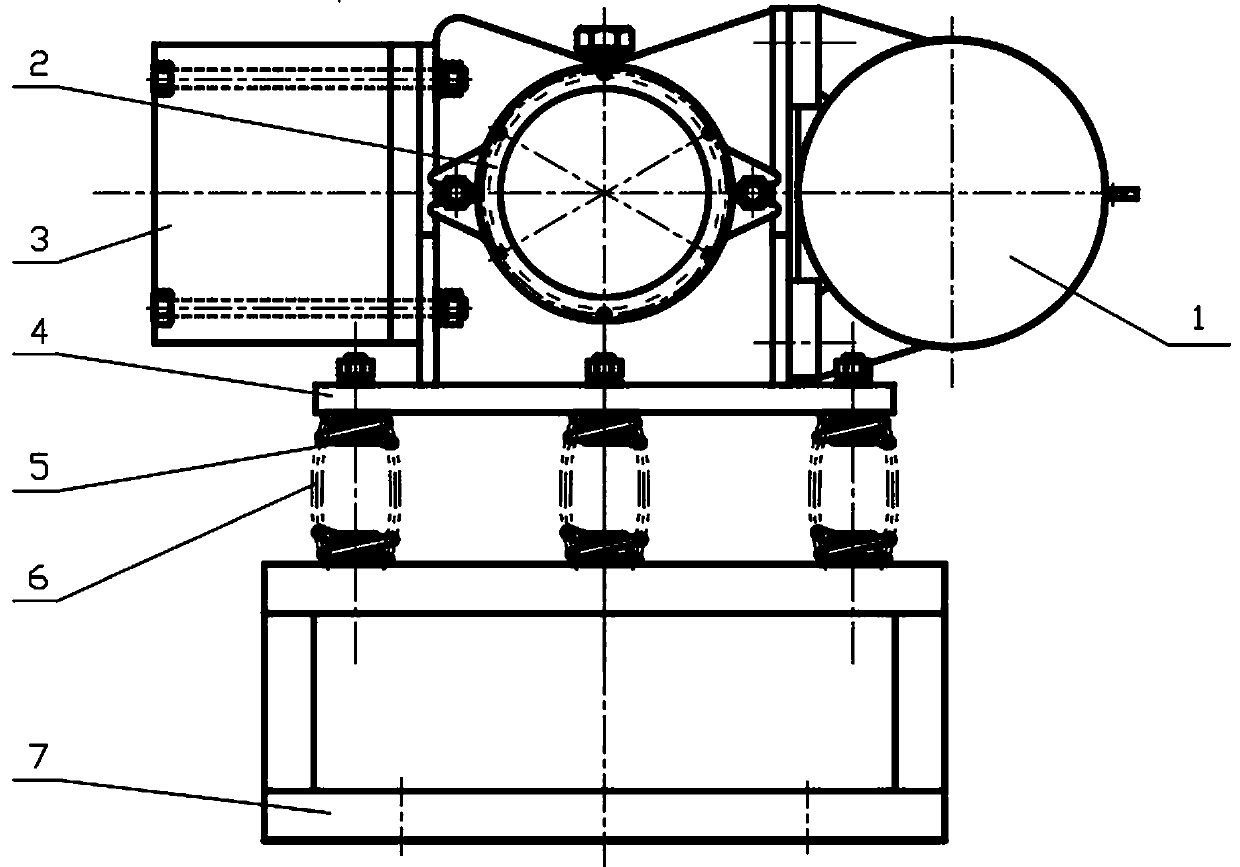

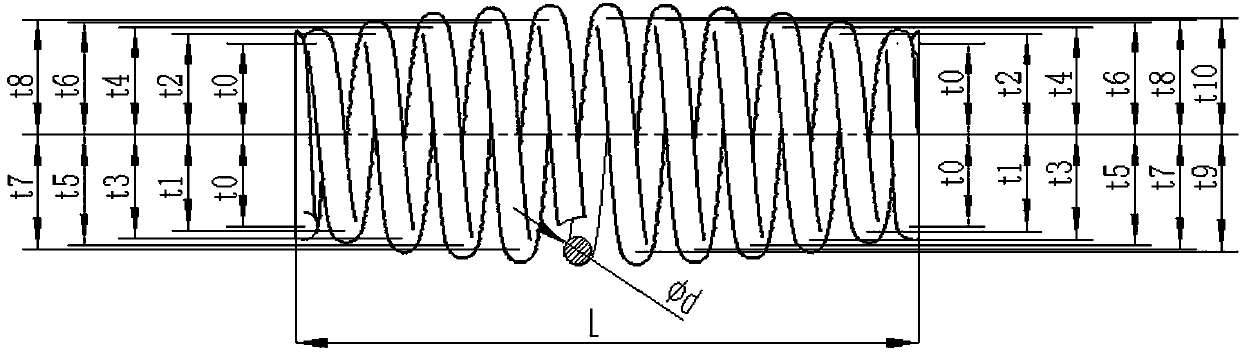

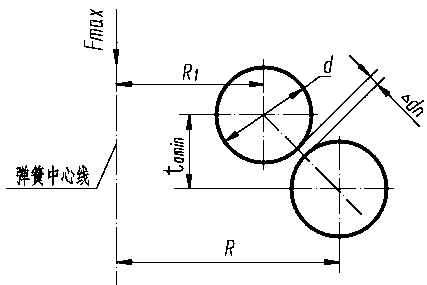

[0028] figure 1Shown is a schematic structural diagram of the vibration mill of the present invention. The mill mainly consists of a vibration motor 1 , a grinding cylinder 2 , a counterweight 3 , an upper body frame 4 , a spring guide post 5 , a spring group 6 and a base 7 . The filling factor of the grinding media in the cylinder can be set to 70%. The grinding media are wear-resistant steel balls and tungsten steel balls. The ratio of the two types of grinding media is 6:4. mm, the material is ultra-hard fine powder, the vibration frequency of the mill is 1450 rpm, the measured amplitude is <22mm, and the vibration intensity is <20.

[0029] like figure 1 As sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap