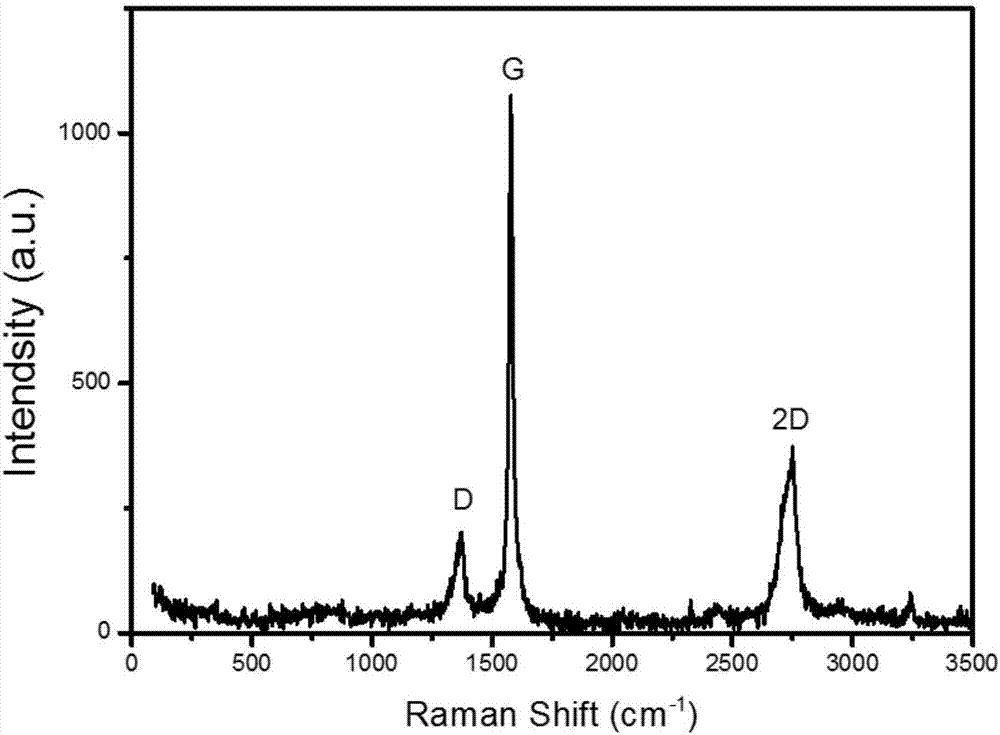

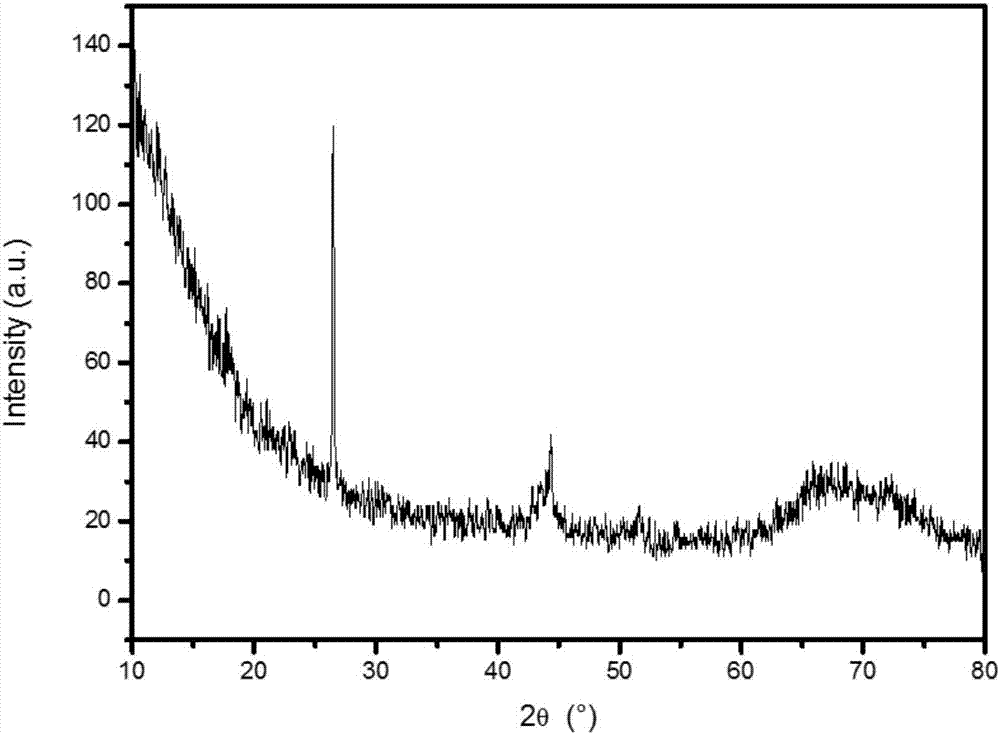

Preparation method and application of graphene-like structured carbon electrode material

A technology of graphene and carbon electrodes, which is applied in the direction of carbon preparation/purification, hybrid capacitor electrodes, etc., can solve the problems of difficult conversion of achievements, and achieve the effects of low cost, abundant raw materials, and good hierarchical pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

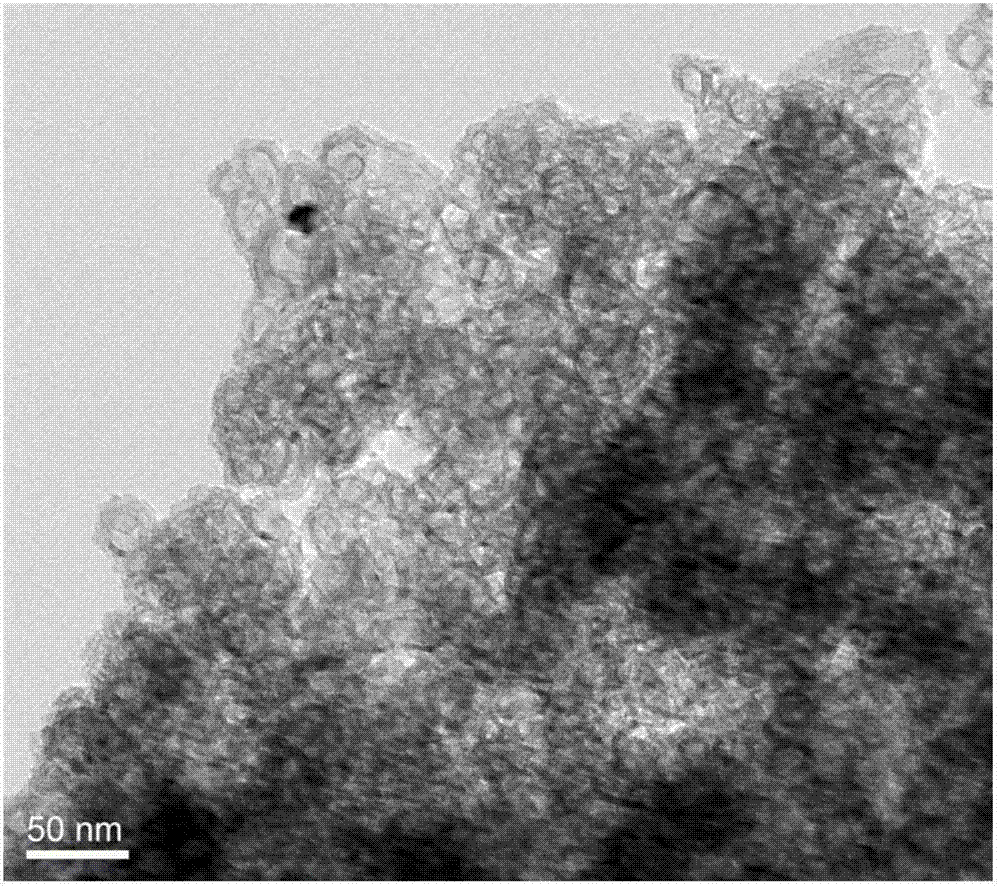

[0038] A method for preparing a graphene-like structure carbon electrode material using biomass rice husk as a raw material includes the following steps:

[0039] Step 1: Dry the rice husks at 60°C.

[0040] Step 2: Stir and mix the dried rice husk in an aqueous solution of nickel nitrate, soak in it for 12 hours and bake it at 60°C for 24 hours. At this time, there is no obvious moisture on the surface of the rice husk; the quality of nickel nitrate is the quality of the dried rice husk Of 5%.

[0041] Step 3: Put the treated material in step 2 in a tube furnace, heat it up to 700°C at a temperature increase rate of 10°C / min in a nitrogen atmosphere for 1 hour, perform carbonization and catalysis, to obtain a preliminary carbonized product.

[0042] Step 4: Place the preliminary carbonized product in Step 3 in a 1mol / L nitric acid solution, soak and stir for 24 hours, filter with suction, wash with water, and dry at 80°C for 12 hours to obtain a carbonized product.

[0043] Step 5: Mi...

Embodiment 2

[0051] A method for preparing a graphene-like structure carbon electrode material using biomass rice husk as a raw material includes the following steps:

[0052] Step 1: Dry the rice husks at 70°C.

[0053] Step 2: Stir and mix the dried rice husk in an aqueous solution of nickel chloride, soak it in it for 12 hours and bake it at 55°C for 36 hours. At this time, there is no obvious moisture on the surface of the rice husk; the quality of the nickel chloride is that of dried rice. 5% of shell mass.

[0054] Step 3: Put the processed material in step 2 in a tube furnace, heat it up to 650°C at a heating rate of 8°C / min in a nitrogen atmosphere and hold for 1.5h, perform carbonization and catalysis, to obtain a preliminary carbonized product.

[0055] Step 4: Place the preliminary carbonized product in Step 3 in a 0.5mol / L hydrochloric acid solution, soak and stir for 24 hours, filter with suction, wash with water, and dry at 100° C. for 12 hours to obtain a carbonized product.

[0056]...

Embodiment 3

[0060] A method for preparing a graphene-like structure carbon electrode material using biomass rice husk as a raw material includes the following steps:

[0061] Step 1: Dry the rice husks at 80°C.

[0062] Step 2: Stir and mix the dried rice husk in an aqueous solution of nickel nitrate, soak in it for 12 hours and bake it at 65°C for 24 hours. At this time, the surface of the rice husk has no obvious moisture; the quality of nickel nitrate is the quality of the dried rice husk Of 5%.

[0063] Step 3: Put the processed material in step 2 in a tube furnace, heat it up to 750°C at a heating rate of 5°C / min in a nitrogen atmosphere, and hold for 1.5h, perform carbonization and catalysis, to obtain a preliminary carbonized product.

[0064] Step 4: Place the preliminary carbonized product in Step 3 in a 5mol / L nitric acid solution, soak and stir for 24 hours, filter with suction, wash with water, and dry at 120°C for 12 hours to obtain a carbonized product.

[0065] Step 5: Mix the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com