Preparation method for single-layer molybdenum disulfide nanosheets

A single-layer molybdenum disulfide, molybdenum disulfide technology, applied in the directions of molybdenum sulfide, nanotechnology, bulk chemical production, etc., can solve the problems of long time consumption, low yield, inability to prepare nanosheets on a large scale and high efficiency, etc. Achieve the effect of short time consumption, high yield, and weakening of interlayer van der Waals forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of single-layer molybdenum disulfide nanosheets, comprising the steps of:

[0033] (1) 250 mg of molybdenum disulfide powder with a particle size of less than 2 μm, 100 mg of chitosan powder, 1 g of 1-butyl-3-methylimidazolium hexafluorophosphate and 10 mL of N-methylpyrrolidone were uniformly mixed and transferred to a closed glass container, obtain the first dispersion;

[0034] (2) Place the glass container in an ultrasonic cleaner, and after processing for 2 hours under the condition of 120W power, centrifuge the treated liquid for 15 minutes at 12000 rpm to collect the precipitate;

[0035] (3) Disperse the precipitate in 0.5% acetic acid solution, centrifuge at 12000 rpm for 15 minutes and collect the precipitate, repeat twice;

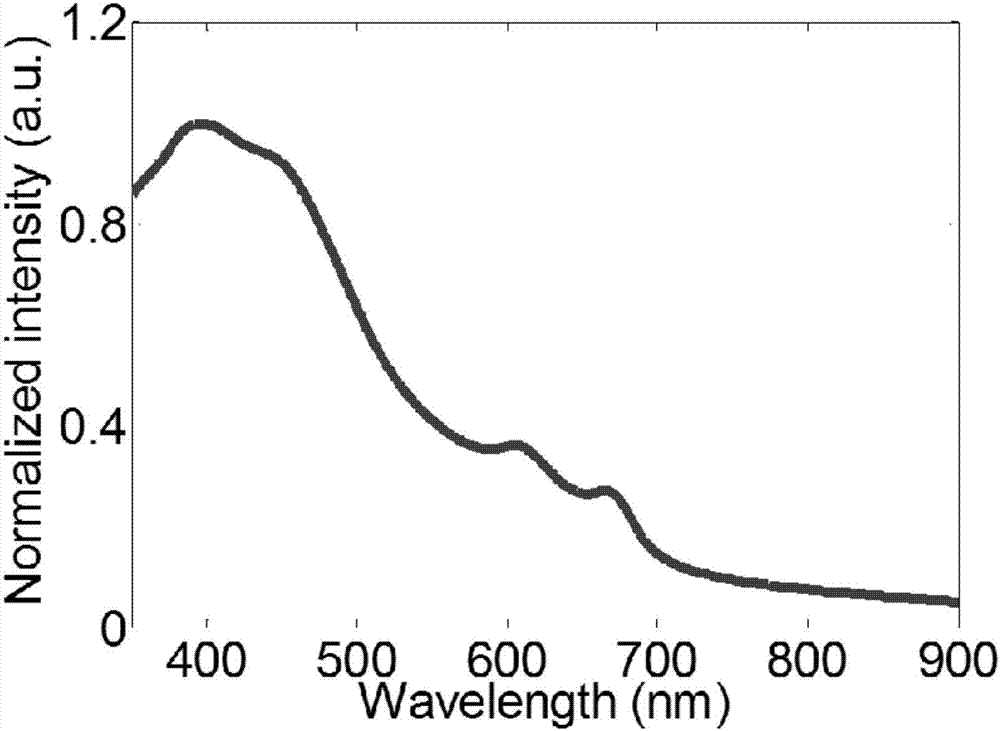

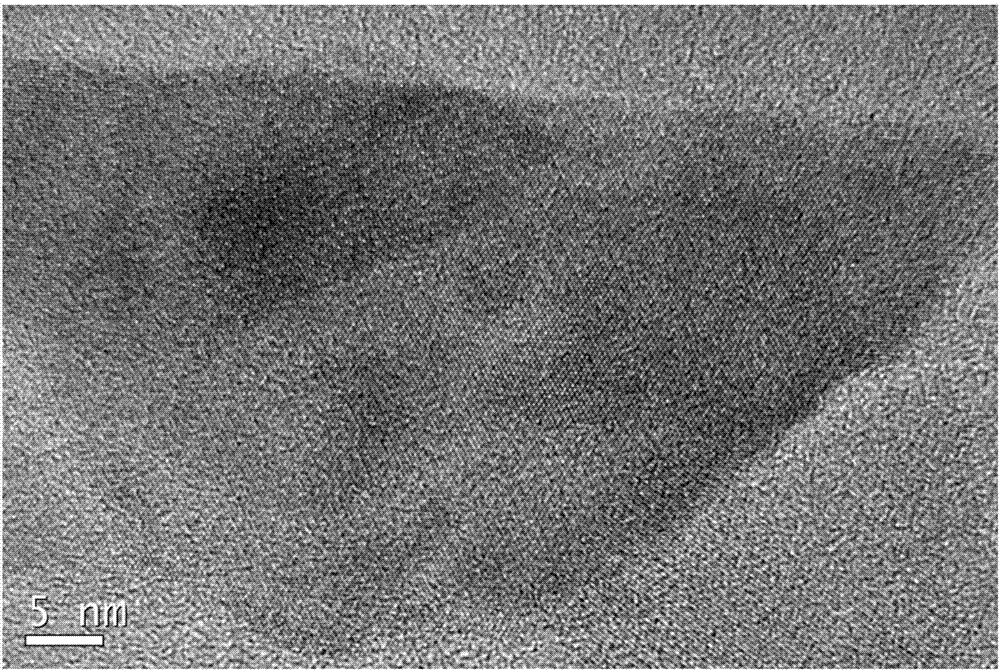

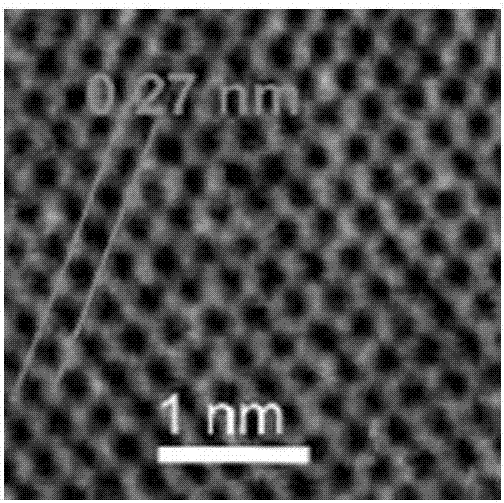

[0036] (4) Disperse the precipitate in deionized water, centrifuge at 4000 rpm for 30 minutes, collect 50 mL of the supernatant to obtain a single-layer molybdenum disulfide nanosheet solution, and disulfide disulfid...

Embodiment 2

[0039] A preparation method of single-layer molybdenum disulfide nanosheets, comprising the steps of:

[0040] (1) 200mg of molybdenum disulfide powder with a particle size of less than 2 μm, 90mg of chitosan powder, 1.1g of 1-butyl-3-methylimidazolium hexafluorophosphate and 12mL of N,N-dimethylformamide were uniformly mixed and Transfer to airtight glass container, obtain the first dispersion liquid;;

[0041] (2) Place the glass container in an ultrasonic cleaning machine, and after processing it for 2.5 hours at a power of 100W, centrifuge the treated liquid at 10,000 rpm for 20 minutes to collect the precipitate;

[0042](3) Disperse the precipitate in 0.5% acetic acid solution, centrifuge at 15000 rpm for 10 minutes and collect the precipitate, repeat twice;

[0043] (4) The precipitate was dispersed in deionized water, centrifuged at 4500 rpm for 20 minutes, and 50 mL of the supernatant was collected to obtain a single-layer molybdenum disulfide nanosheet solution.

...

Embodiment 3

[0046] A preparation method of single-layer molybdenum disulfide nanosheets, comprising the steps of:

[0047] (1) 250 mg of molybdenum disulfide powder with a particle size of less than 2 μm, 110 mg of chitosan powder, 1.2 g of 1-butyl-3-methylimidazolium hexafluorophosphate and 15 mL of ethanol were uniformly mixed and transferred to a closed glass container to obtain the first a dispersion;

[0048] (2) Place the glass container in an ultrasonic cleaning machine, and after processing it for 1.5 hours at a power of 150W, centrifuge the treated liquid at 15,000 rpm for 10 minutes to collect the precipitate;

[0049] (3) Disperse the precipitate in 0.5% acetic acid solution, centrifuge at 10,000 rpm for 20 minutes and collect the precipitate, repeat twice;

[0050] (4) The precipitate was dispersed in deionized water, centrifuged at 3500 rpm for 40 minutes, and 50 mL of the supernatant was collected to obtain a single-layer molybdenum disulfide nanosheet solution.

[0051] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com