A kind of polycarbonate polyol and its preparation method and application

A polycarbonate and polyol technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of lowering the glass transition temperature, reducing the chemical resistance of finished products, and the polyurethane film is too soft, achieving excellent mechanical strength, good Effects of mechanical properties and widening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

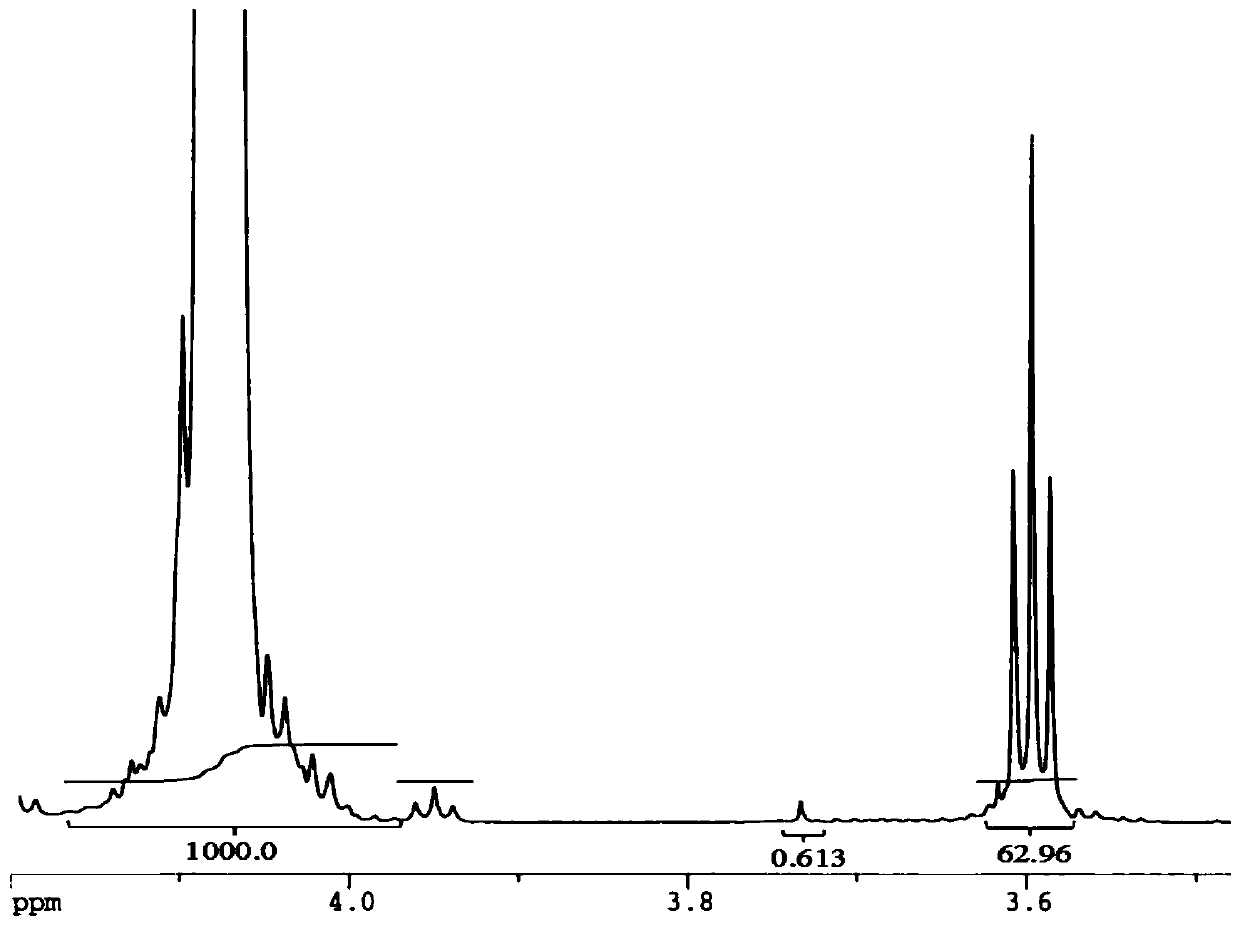

[0102] Firstly, the four-neck reaction flask was connected to the condensing device and set up, and the air-nitrogen replacement was performed back and forth three times. At this time, the nitrogen gas was turned on, and 1 mole (118 g) of 1,6-hexanediol was added into the reactor, the temperature of the reactor was raised to 100° C., and water was removed under vacuum for 1 hour. Afterwards, fill up nitrogen again, lower the temperature to 60°C, add a small amount of catalyst sodium hydride and 1.285 moles (115.6 grams) of dimethyl carbonate into the reactor and mix evenly, adjust the reaction temperature to 80°C, and the temperature at the top of the tower can be observed to rise to 60-64°C, and remove methanol and dimethyl carbonate, and record the amount of liquid removed.

[0103] Then slowly increase the reaction temperature until 190°C, set up a vacuum system device, and depressurize to 20mmHg; then check the viscosity and hydroxyl value every hour until the hydroxyl val...

Embodiment 2

[0106] First, the reactor was set up, and the air-nitrogen replacement was performed back and forth three times. At this time, the nitrogen gas was turned on, and 1 mole (104 g) of 1,5-pentanediol was added into the reactor, and the temperature of the reactor was raised to 100° C., and water was removed under vacuum for 1 hour. Afterwards, fill up with nitrogen again, lower the temperature to 60°C, add a small amount of catalyst sodium hydride and 1.294 moles (116.46 grams) of dimethyl carbonate into the reactor and mix evenly, adjust the reaction temperature to 80°C, and the temperature at the top of the tower can be observed to rise to 60-64°C, and remove methanol and dimethyl carbonate, and record the amount of liquid removed.

[0107] Then slowly increase the reaction temperature until it reaches 190°C, put a vacuum system on it, and reduce the pressure to 20mmHg; then check the viscosity and hydroxyl value every hour until the hydroxyl value shows that the obtained polyca...

Embodiment 3

[0110] First, the reactor was set up, and the air-nitrogen replacement was performed back and forth three times. At this time, the nitrogen gas was turned on, and 1.5 moles (135 grams) of 1,4-butanediol was added into the reactor, and the temperature of the reactor was raised to 100° C., and water was removed under vacuum for 1 hour. Afterwards, fill up nitrogen again, lower the temperature to 60°C, add a small amount of catalyst sodium hydride and 1.955 moles (175.99 grams) of dimethyl carbonate into the reactor and mix evenly, adjust the reaction temperature to 80°C, and the temperature at the top of the tower can be observed to rise to 60°C, remove methanol and dimethyl carbonate, and record the amount of removed liquid.

[0111] Then slowly increase the reaction temperature until it reaches 190°C, put a vacuum system on it, and reduce the pressure to 20mmHg; then check the viscosity and hydroxyl value every hour until the hydroxyl value shows that the obtained polycarbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com