Polyester resin having good stone chip-resistant performance used for transparent powdery paint and preparation method thereof

A powder coating and anti-stone chip technology, which is applied in the direction of powder coatings, etc., can solve the problems of transparent powder coating film transparency and poor leveling, surface hardness and toughness of the coating film, etc., to achieve excellent leveling, good stone resistance Impact performance, enhance the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

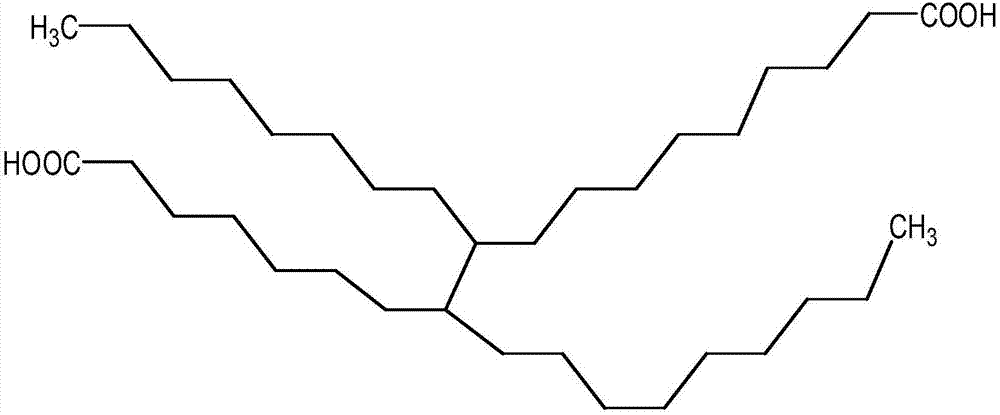

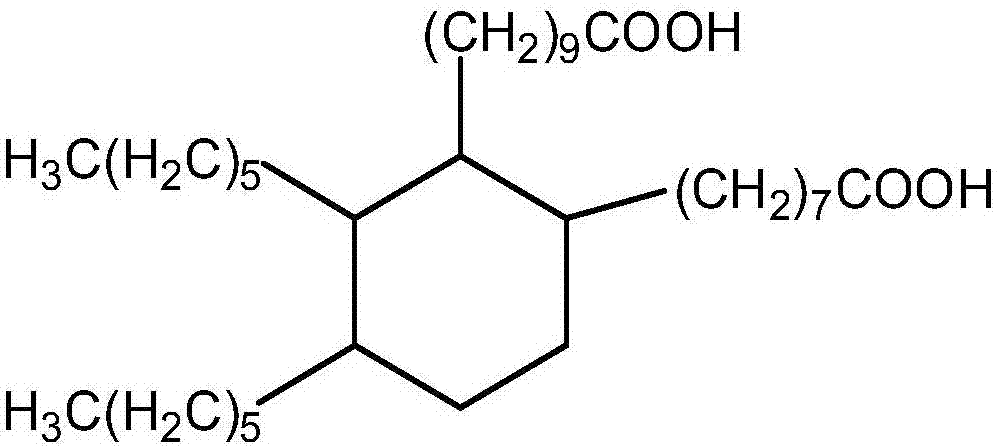

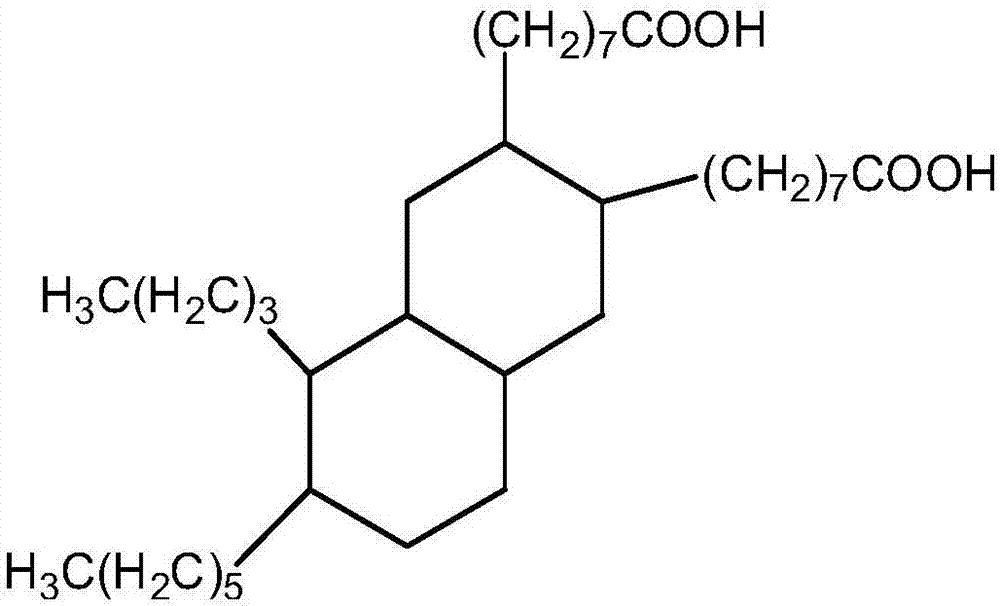

Method used

Image

Examples

Embodiment A

[0043] The specific implementation of the synthesis process is: (1) in a 3000ml reactor equipped with a heating device, agitator and a distillation column, the polyol component A (wherein 775 parts of neopentyl glycol ), heated to 110-130°C under normal pressure; 1165 parts by mass of the proportioning amount was added to be polyacid component B (990 parts of terephthalic acid, 100 parts of isophthalic acid, 75 parts of adipic acid) and 2.5 parts by mass of esterification catalyst component D (including 2.5 parts of monobutyltin oxide), the temperature was gradually raised while stirring. (2) The temperature of the material rises to 165-175°C, the esterification reaction begins, and the esterification water begins to be generated and steamed out through the distillation column. The steam temperature at the top of the distillation column is controlled at 99°C ± 2°C; Esterification water is distilled out, and when the temperature of the material rises to 245°C ± 2°C, heat preser...

Embodiment B

[0045] The specific implementation of the synthesis process is: (1) in a 3000ml reactor equipped with a heating device, agitator and a distillation column, the polyol component A (wherein 695 parts of neopentyl glycol , 60 parts of 1,4-cyclohexanedimethanol), and the temperature is raised to 110-130°C under normal pressure; then 1090 parts by mass of the proportioning amount are put into polyacid component B (990 parts of terephthalic acid, 100 parts isophthalic acid), 60 parts by mass of hydrogenated dimer acid component C (60 parts of hydrogenated dimer soybean oil fatty acid) and 2.5 parts by mass of esterification catalyst component D (2.5 parts of single Butyltin oxide), gradually heating up while stirring. (2) The temperature of the material rises to 165-175°C, the esterification reaction begins, and the esterification water begins to be generated and steamed out through the distillation column. The steam temperature at the top of the distillation column is controlled at...

Embodiment C

[0047] The concrete implementation synthesis process is: (1) in the 3000ml reactor that is equipped with heating device, agitator and distillation column, the polyol component A (wherein 660 parts of neopentyl glycol , 60 parts of 2-methyl-1,3-propanediol, 60 parts of 1,4-cyclohexanedimethanol), and the temperature is raised to 110-130°C under normal pressure; Component B (990 parts of terephthalic acid, 80 parts of isophthalic acid, 60 parts of 1,4-cyclohexanedicarboxylic acid), 90 parts by mass of hydrogenated dimer acid component C (90 parts of Hydrogenated dimerized tall oil fatty acid) and the esterification catalyst component D (wherein 2.5 parts of monobutyltin oxide) that mass fraction is 2.5 parts, while stirring, gradually heat up. (2) The temperature of the material rises to 165-175°C, the esterification reaction begins, and the esterification water begins to be generated and steamed out through the distillation column. The steam temperature at the top of the distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com