Direct reduction roasting-magnetic separation red mud comprehensive using method based on rotary kiln

A technology of rotary kiln and red mud, which is applied in the field of comprehensive resource utilization, can solve the problems of environmental pollution, large manpower and material resources for stockpiling red mud, waste of resources, etc., and achieves the advantages of convenient operation and management, comprehensive utilization and high recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

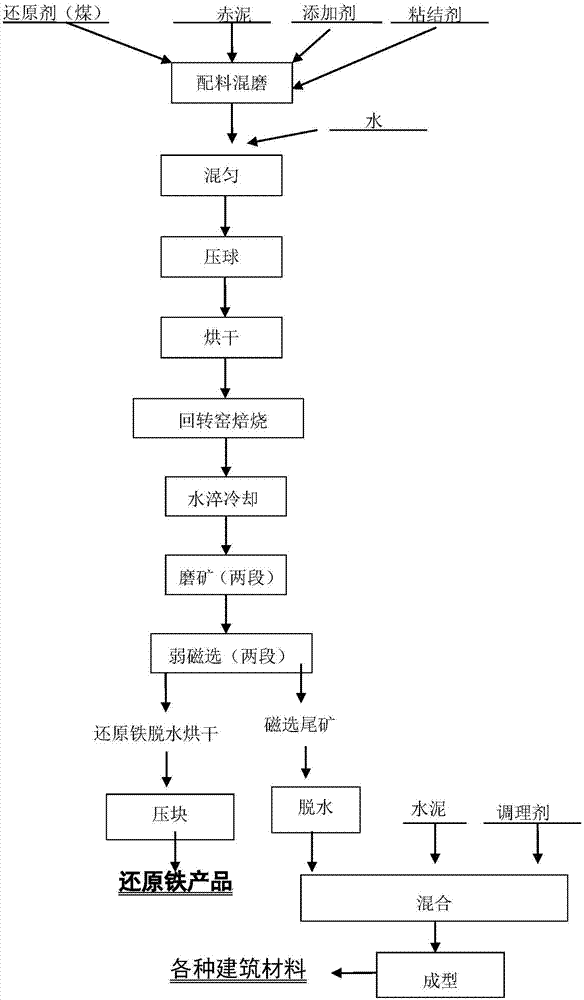

Image

Examples

Embodiment 1

[0024] The chemical composition of the red mud used is shown in Table 1.

[0025] Table 1 Main chemical components of red mud used

[0026] Element

Fe

Ai 2 o 3

SiO 2

Na 2 o

CaO

MgO

Cr

content

33.20

18.20

12.20

8.19

15.70

0.69

0.29

12.50

[0027] Firstly, batching is carried out, and the mass ratio of batching is: red mud: coal powder: seaside titanium magnetite: modified starch: bentonite: water=100:25:8.5:2.5:4.5:7.5. Among them, the iron grade of seaside titanium magnetite is 54.21%, TiO 2 Content of 9.5%, coal powder is bituminous coal with fixed carbon mass fraction of 57.5%, volatile matter of 26.5%, and ash content of 15.2%. After all the materials are mixed evenly, they are pressed into balls on a ball pressing machine under a pressure of 11.5MPa, and the balls are dried at 230°C for 60 minutes.

[0028] The dried balls were calcined at 1290° C. for 4.5 hours, and the calcine...

Embodiment 2

[0031] The chemical composition of the red mud used is shown in Table 2.

[0032] Table 2 Main chemical components of red mud used

[0033] Element

Fe

Ai 2 o 3

SiO 2

Na 2 o

CaO

MgO

Cr

S

content(%)

46.91

7.90

5.01

1.82

0.35

0.09

0.29

0.095

15.80

[0034] Firstly, batching is carried out, and the batching mass ratio is: red mud: coal powder: seaside titanium magnetite: modified starch: bentonite: water = 100:30:9.5:2.5:3.5:8.5. Among them, the iron grade of seaside titanium magnetite is 55.45%, TiO 2 The content is 8.7%, the pulverized coal is bituminous coal with a fixed carbon mass fraction of 57.5%, a volatile matter of 12.3%, and an ash content of 21.2%. After all the materials are mixed evenly, they are pressed into balls on a ball pressing machine under a pressure of 11.5MPa, and the balls are dried at 230°C for 60 minutes.

[0035] The dried balls were calcined at 1285° C...

Embodiment 3

[0038] The chemical composition of the red mud used is shown in Table 3.

[0039] Table 3 Main chemical components of red mud used

[0040] Element

Fe

Ai 2 o 3

SiO 2

Na 2 o

CaO

MgO

Cr

S

content(%)

35.28

12.54

11.15

5.60

7.56

1.56

0.29

0.095

10.80

[0041] Firstly, batching is carried out, and the batching mass ratio is: red mud: coal powder: seaside titanium magnetite: modified starch: bentonite: water = 100:27:10.0:2.5:3.5:9. Among them, the iron grade of seashore titanium magnetite is 54.87%, TiO 2 Content of 9.0%, coal powder is bituminous coal with fixed carbon mass fraction of 55.7%, volatile matter of 18.3%, and ash content of 24.8%. After all the materials are mixed evenly, they are pressed into balls on a ball pressing machine under a pressure of 11.5MPa, and the balls are dried at 230°C for 60 minutes.

[0042] The dried balls were calcined at 1300° C. for 4.8 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com