Sol-gel method for preparing water treatment metal oxide film

A technology of water treatment membrane and gel method, which is applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, membrane technology, etc. It can solve problems such as difficult to control operation and high temperature exceeding 1000°C, and achieve low synthesis temperature, The effect of low preparation cost and easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

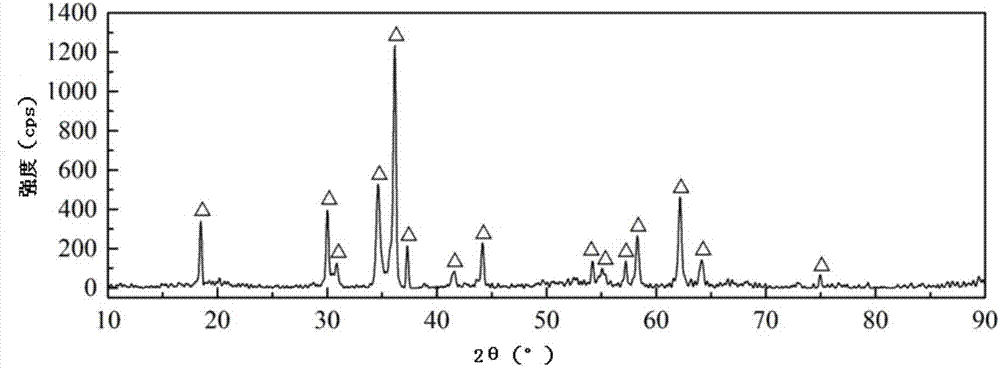

[0020] Specific embodiment one: In this embodiment, a method for preparing a metal oxide water treatment membrane by a sol-gel method is specifically carried out according to the following steps:

[0021] 1. Add metal nitrate to deionized water, then add citric acid, heat and stir evenly with magnetic force, then add ethylene glycol, heat and stir evenly with magnetic force, control the temperature at 95°C, heat and stir in an oil bath to obtain a sol;

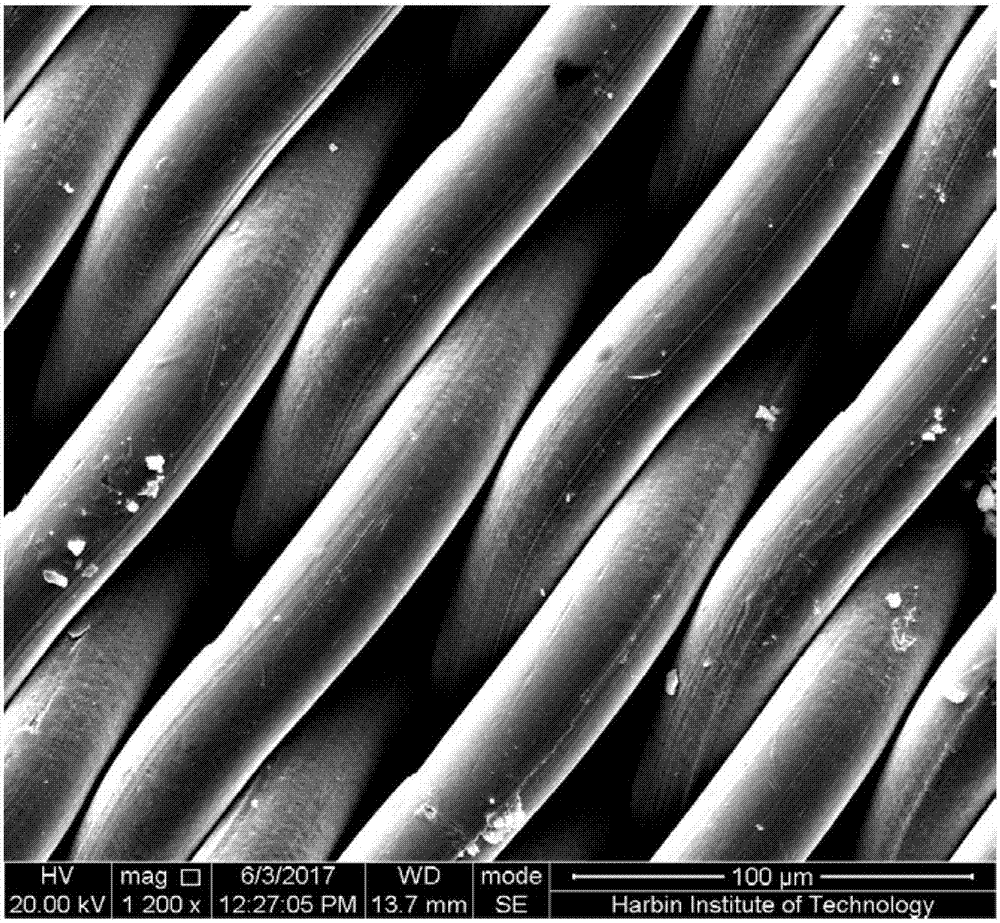

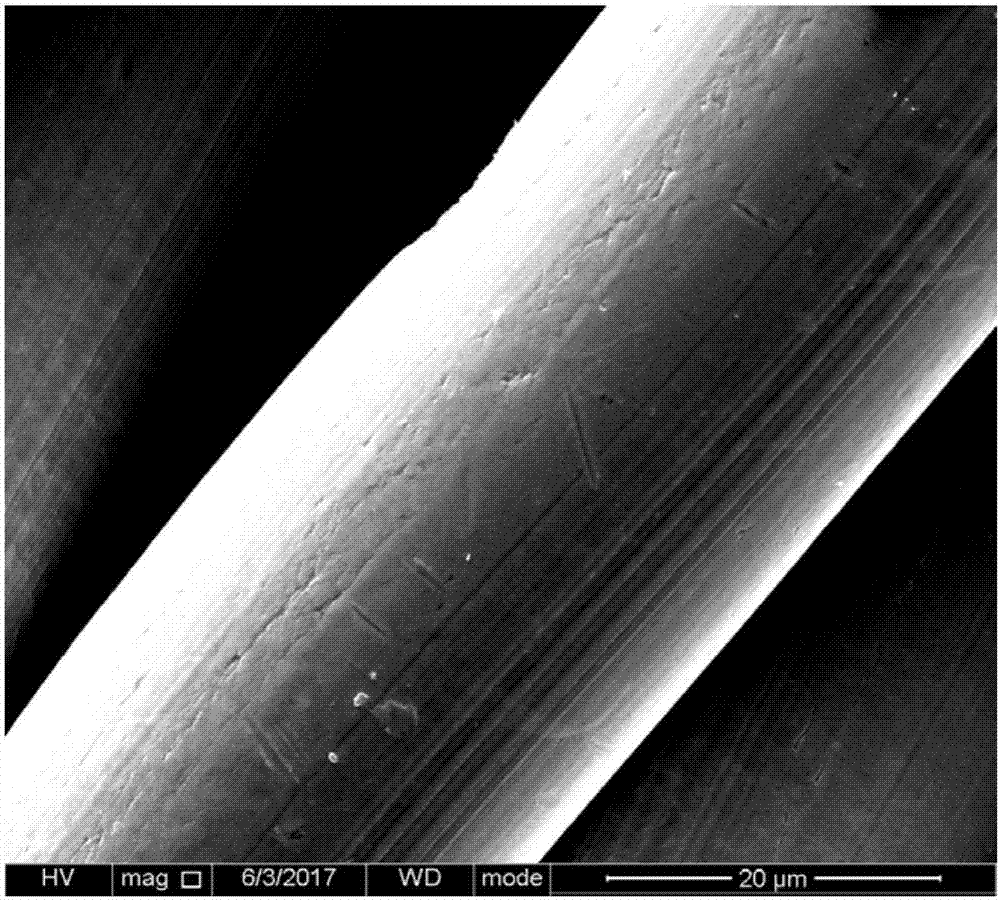

[0022] 2. Clean and dry the stainless steel mesh; the pore size of the stainless steel mesh is 3 μm;

[0023] 3. Put the stainless steel mesh processed in step 2 into a glue homogenizer, spin-coat the sol obtained in step 1, then dry, and repeat the spin-coating and drying for 3 to 5 times to obtain a coated stainless steel mesh;

[0024] 4. Put the stainless steel mesh coated in step 3 into a muffle furnace, heat it to 700-900°C by means of temperature programming, keep it warm for 0.5h-2h, and cool it to room temperature wit...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the metal nitrate in step 1 is one or a mixture of any two of iron nitrate, copper nitrate, manganese nitrate, aluminum nitrate and calcium nitrate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: metal nitrate is the mixing of ferric nitrate and copper nitrate in step one, wherein Cu(NO 3 ) 2 ·3H 2 O and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 1:2. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com