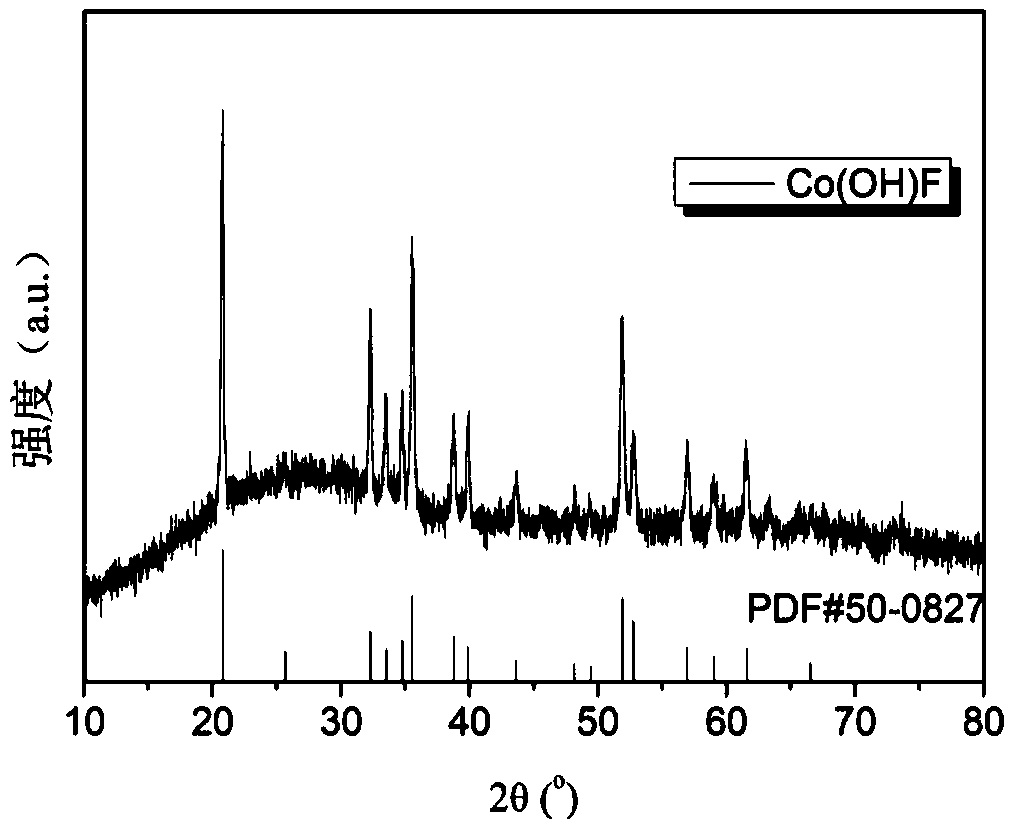

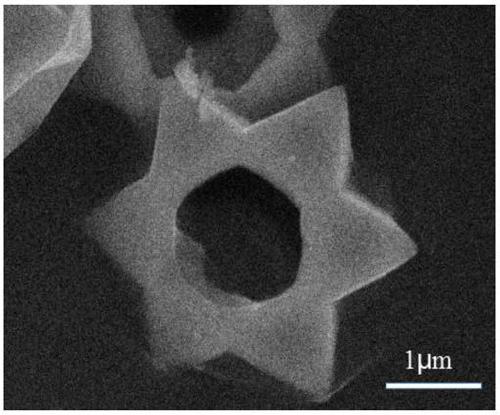

A lithium-ion battery negative electrode material co(oh)f with hexagonal star structure and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, structural parts, etc., can solve problems such as unfavorable large-scale production synthesis, harsh experimental environment requirements, single morphology, etc., and achieve good cycle stability. Beneficial for infiltration and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step (1): 0.074g NH 4 Dissolve F in 40ml of deionized water, stir evenly, add 1g of polyvinylpyrrolidone, and continue stirring until the solution becomes clear;

[0038] Step (2): 0.291g Co(NO 3 ) 2·6H 2 O was dissolved in 20ml alcohol and stirred evenly;

[0039] Step (3): under stirring conditions, the Co(NO 3 ) 2 ·6H 2 O alcohol solution was added dropwise to the NH in step (1) 4 F and polyvinylpyrrolidone mixed solution;

[0040] Step (4): Place the mixed solution obtained in step (3) in a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven with a temperature of 200°C, keep it warm for 2 hours, and then cool it naturally to room temperature;

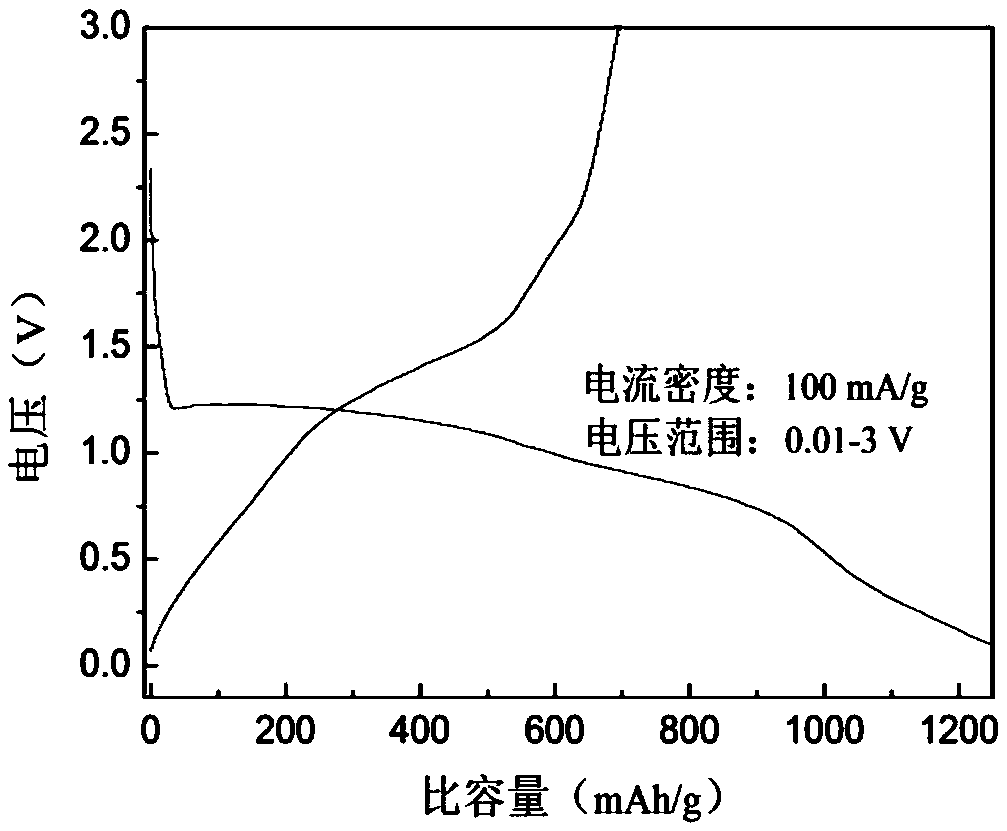

[0041] Step (5): The pink precipitate obtained in step (4) was centrifuged and washed 3 times with ethanol, and dried in a vacuum oven at 80° C. for 4 hours to obtain a lithium-ion battery negative electrode material. As a lithium-ion battery negative electrode material for electro...

Embodiment 2

[0043] Step (1): 0.30g NH 4 Dissolve F in 40ml deionized water, stir well, add 0.5g cetyltrimethylammonium bromide, and continue stirring until the solution is clear;

[0044] Step (2); 0.714g CoCl 2 ·6H 2 O was dissolved in 20ml alcohol and stirred evenly;

[0045] Step (3): under stirring condition, the CoCl in the step (2) 2 ·6H 2 O alcohol solution was added dropwise to the NH in step (1) 4 F and cetyltrimethylammonium bromide mixed solution;

[0046] Step (4): Place the mixed solution obtained in step (3) in a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven with a temperature of 150° C., keep it warm for 24 hours, and then cool it naturally to room temperature;

[0047] Step (5): The pink precipitate obtained in step (4) was centrifuged and washed 3 times with ethanol, and dried in a vacuum oven at 80° C. for 4 hours to obtain a lithium-ion battery negative electrode material. As a lithium-ion battery negative electrode mater...

Embodiment 3

[0049] Step (1): Dissolve 0.168g of NaF in 40ml of deionized water at room temperature, stir well, add 0.8g of polyethylene glycol, and continue stirring until the solution becomes clear;

[0050] Step (2); 0.374g Co(CH 3 COO) 2 4H 2 O was dissolved in 20ml alcohol and stirred evenly;

[0051] Step (3): under stirring conditions, the Co(CH 3 COO) 2 4H 2 O alcohol solution is added dropwise to the NaF and polyethylene glycol mixed solution in step (1);

[0052] Step (4): Place the mixed solution obtained in step (3) in a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven with a temperature of 80° C., keep it warm for 48 hours, and then cool it naturally to room temperature;

[0053] Step (5): The pink precipitate obtained in step (4) was centrifuged and washed 3 times with ethanol, and dried in a vacuum oven at 80° C. for 4 hours to obtain a lithium-ion battery negative electrode material. As a lithium-ion battery negative electrode m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com