Process method for treating oily sludge of oil field

A process method and technology for landing oil sludge, applied in the field of oil sludge treatment, can solve the problems of increasing the secondary pollution of oil sludge, failing to realize resource treatment and addition, etc., and achieve the effect of realizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

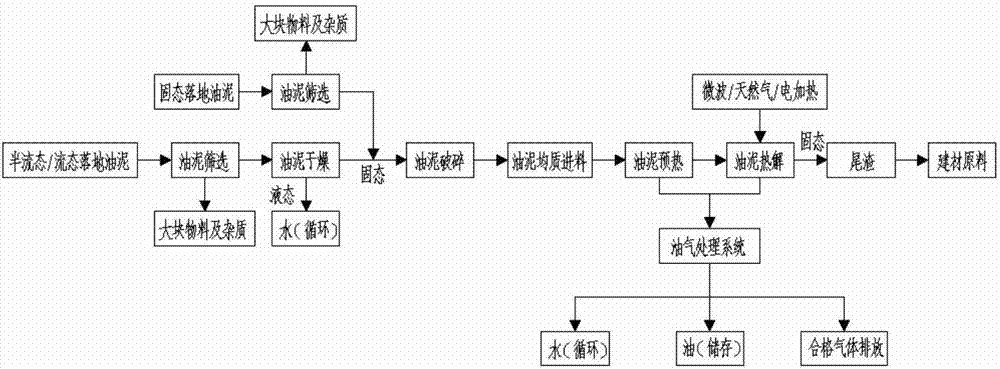

Embodiment 1

[0033] Taking the semi-fluid landed oil sludge as an example, firstly screen out large pieces and impurities, dry and crush to obtain oil sludge with a moisture content of less than 40% and a particle size of less than 20mm, which is evenly laid on the steel belt through a homogeneous feeding system , follow the assembly line for preheating and pyrolysis to generate tailings with an oil content of <3‰, which are used as raw materials for industrial land or building materials, and the tail gas generated enters the oil and gas treatment system, through condensation, oil-water separation, high-temperature incineration, desulfurization and denitrification, activated carbon adsorption, etc. Turned into oil, water, and exhaust gas up to standard.

Embodiment 2

[0035] Taking the solid ground oil sludge as an example, firstly, large pieces and impurities are screened out, and crushed to obtain oil sludge with a particle size of less than 20mm, which is evenly laid on the steel belt through a homogeneous feeding system, followed by preheating and pyrolysis along the assembly line, Tailings with an oil content of <3‰ are generated and used as raw materials for industrial land or building materials. The tail gas generated enters the oil and gas treatment system, and becomes oil, water, and emission standards through condensation, oil-water separation, high-temperature incineration, desulfurization and denitrification, and activated carbon adsorption. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com