Gradient pore silicon carbide ceramic filter plate and preparation method thereof

A technology of silicon carbide ceramics and filter plates, which is applied in ceramic products, other household utensils, applications, etc., can solve the problems of easy blockage of pores, easy peeling of ceramsite, and low strength of filter plates, so as to reduce grain loss and improve mechanical strength , The effect of high opening porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

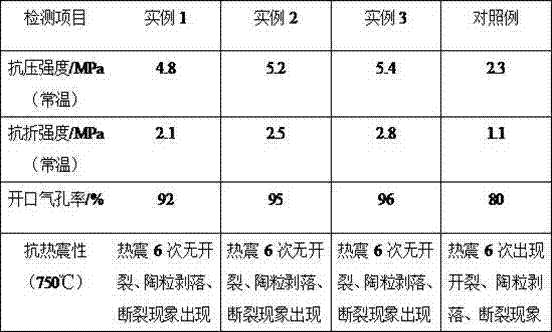

Examples

example 1

[0025]Cut the flexible polyurethane foam with coarse, medium and fine pores into discs of the same size, soak them in 10% sodium hydroxide solution at 60°C for 2 hours, take out the flexible polyurethane foam and use After washing with deionized water for 2 times, transfer to mass fraction and soak in 2% sodium carboxymethylcellulose solution for 1h, take out the pretreated soft polyurethane foam, then weigh 450g silicon carbide, 100g kaolin, 110g potassium feldspar, Put 50g of bentonite, 50g of alumina, 30g of white corundum, 10g of talc powder, and 50g of silicon micropowder into a ball mill for ball milling, and screen out composite powders with particle sizes of 25-100 μm, 15-25 μm, and 0.5-15 μm, respectively. Take 100g of composite powder with different particle sizes and mix with 50g of deionized water, stir and mix evenly, then add 15g of aluminum dihydrogen phosphate, stir evenly to obtain ceramic slurry with different particle sizes, and immerse the coarse-pore pretre...

example 2

[0027] Cut the flexible polyurethane foam with coarse, medium and fine pores into discs of the same size, soak in 10% sodium hydroxide solution at 65°C for 3 hours, take out the flexible polyurethane foam and use After washing with deionized water for 3 times, transfer to mass fraction and soak in 2% sodium carboxymethyl cellulose solution for 2h, take out the pretreated soft polyurethane foam, then take by weighing 520g silicon carbide, 110g kaolin, 120g potassium feldspar, Put 55g of bentonite, 55g of alumina, 40g of white corundum, 15g of talc powder, and 65g of silicon micropowder into a ball mill for ball milling, and screen out composite powders with particle sizes of 25-100 μm, 15-25 μm, and 0.5-15 μm, respectively. Take 110g of composite powders with various particle sizes and mix them with 53g of deionized water, stir and mix evenly, then add 16g of aluminum dihydrogen phosphate, stir evenly to obtain ceramic slurry with various particle sizes, and immerse the coarse-p...

example 3

[0029] Cut the soft polyurethane foam with coarse, medium and fine pores into discs of the same size, soak in 10% sodium hydroxide solution at 70°C for 3 hours, take out the flexible polyurethane foam and use After washing with deionized water for 3 times, transfer to mass fraction and soak in 2% sodium carboxymethylcellulose solution for 2h, take out the pretreated soft polyurethane foam, then take by weighing 600g silicon carbide, 120g kaolin, 130g potassium feldspar, 60g of bentonite, 60g of alumina, 50g of white corundum, 20g of talcum powder, and 80g of silicon micropowder were put into a ball mill for ball milling, and the composite powders with a particle size of 25-100μm, 15-25μm, and 0.5-15μm were screened out, and 120g each Mix the composite powder with different particle sizes with 55g deionized water, stir and mix evenly, then add 16g of aluminum dihydrogen phosphate, stir evenly to get ceramic slurry with different particle sizes, and immerse the coarse-pore pretre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com