A kind of water-based transfer direct-plating laser coating for cigarette packs and its preparation method

A water-based, direct-plating technology, applied in the field of coatings, can solve the problems of weak laser effect, difficult production quality control, and easy peeling of the aluminum layer, and achieve the effect of no risk of embossing adhesion, clear laser effect, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

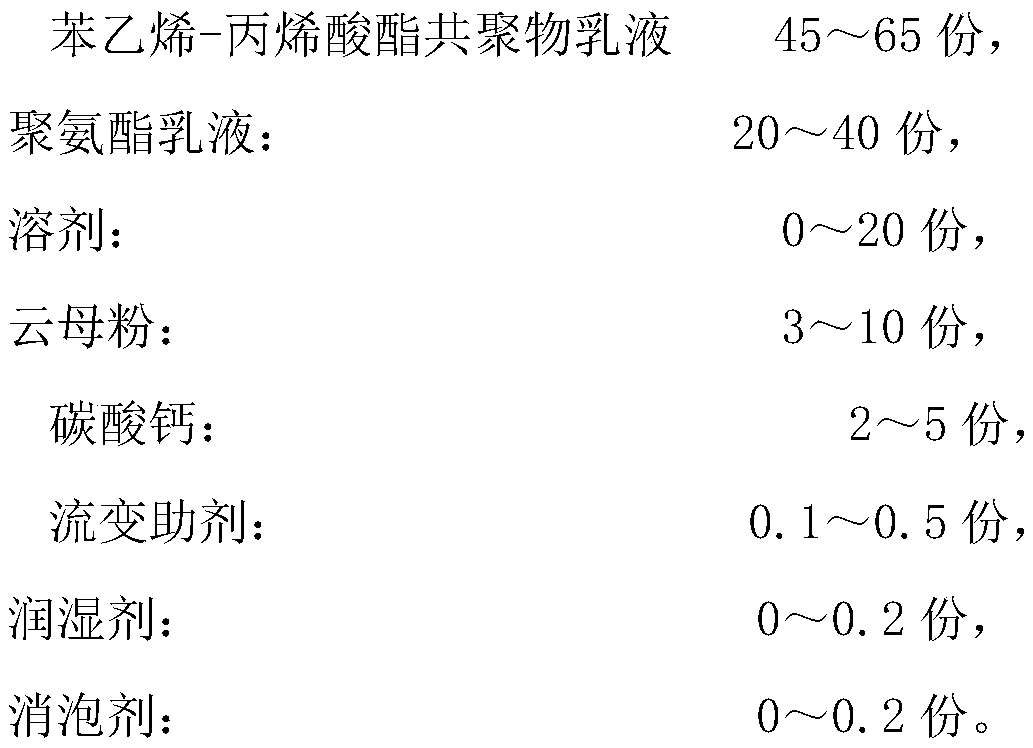

[0039] This embodiment provides a kind of water-based transfer direct-plating laser coating for lining paper of cigarette packs, and the parts by weight of its components are as shown in Table 1:

[0040] Table 1

[0041] Styrene-acrylate copolymer emulsion 45 polyurethane emulsion 40 calcium carbonate 5 Mica powder 10 solvent 0 Rheology Additives 0.5 D 0.2 Defoamer 0.2

[0042] The coating preparation method of the present embodiment comprises the following processing steps:

[0043] A. Mix evenly with styrene-acrylate copolymer emulsion and polyurethane emulsion.

[0044] B. Add the premix of water and ethanol.

[0045] C. Add mica powder and calcium carbonate in turn. .

[0046] D. Add rheological additives, wetting agents, and defoamers in turn, and stir at 1100-1300 rpm for 30 minutes.

[0047] E. The product is obtained after filtering with an 80-mesh filter.

Embodiment 2

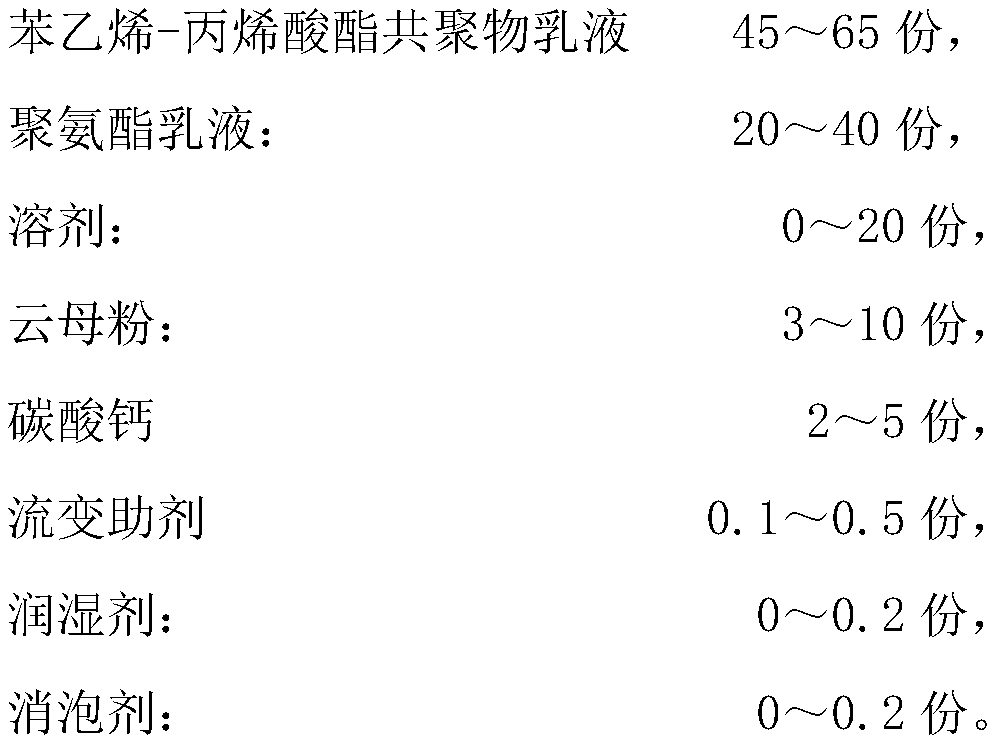

[0049] This embodiment provides a kind of water-based transfer direct-plating laser coating for lining paper of cigarette packs, and the parts by weight of its components are as shown in Table 2:

[0050] Table 2

[0051]

[0052]

[0053] The coating preparation method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0055] This embodiment provides a kind of water-based transfer direct-plating laser coating for lining paper of cigarette packs, and the parts by weight of its components are as shown in Table 3:

[0056] table 3

[0057] Styrene-acrylate copolymer emulsion 50 polyurethane emulsion 25 calcium carbonate 3 Mica powder 5 Water: ethanol = 2:1 17 Rheology Additives 0.5 D 0.1 Defoamer 0.2

[0058] The coating preparation method of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com