Load type perrhenate ionic liquid based cellulose degradation method

A technology of cellulose degradation and ionic liquid, which is applied in chemical instruments and methods, sugar production, sugar production, etc., can solve the problems of catalyst cost increase, unfavorable catalyst recovery and reuse, etc., and achieve high catalyst activity and chemical The effect of stable properties and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

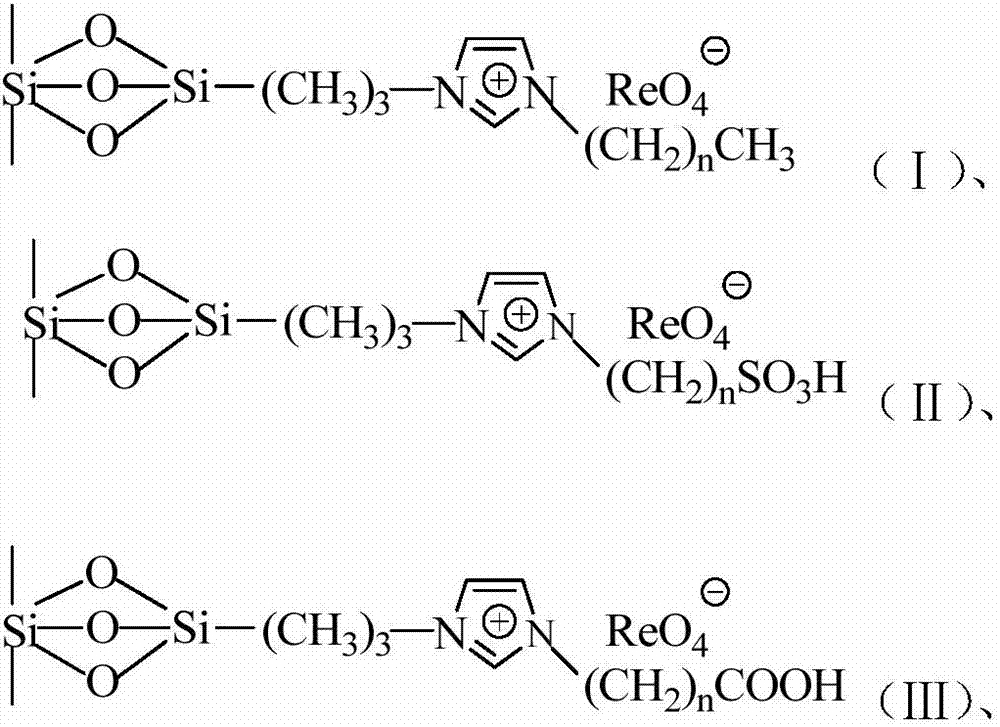

Image

Examples

Embodiment 1

[0025] Example 1 Catalytic degradation of microcrystalline cellulose by supported N-methylimidazolium perrhenate ionic liquid

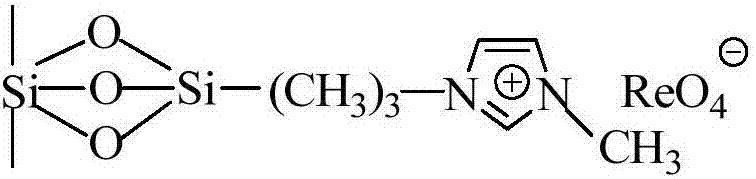

[0026] The structural formula of the loaded N-methylimidazolium perrhenate ionic liquid is shown in the following formula:

[0027]

[0028] Weigh 0.1g of microcrystalline cellulose and 2.0g of 1-allyl-3-methylimidazolium chloride ionic liquid in a 10mL reaction flask, stir well, dissolve at 100°C for 10min, add 0.05g of loaded N- Methylimidazolium perrhenate ionic liquid and 70 μL of water were heated at 150° C. for 30 minutes. After the reaction, the reaction solution was diluted with water and filtered, and the filtrate was settled to 100mL. The TRS was measured by the DNS method, and the reaction product was analyzed by high performance liquid chromatography. The TRS was 78.5.9%, and the glucose yield was 39.3%. %.

Embodiment 2

[0029] Example 2 Catalytic degradation of microcrystalline cellulose by supported 1-(3-sulfonic acid)propyl-3-methylimidazolium perrhenate ionic liquid

[0030] (1) Supported 1-(3-sulfonic acid) propyl-3-methylimidazolium perrhenate ionic liquid

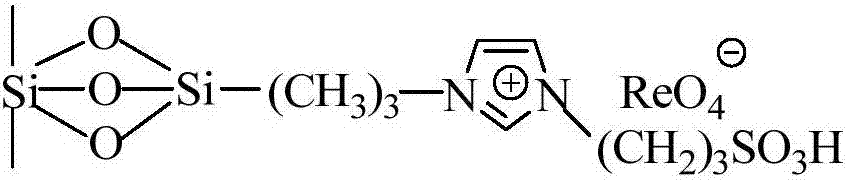

[0031] The structural formula is as follows:

[0032]

[0033] The preparation method is as follows:

[0034]Add 2.0g MCM-41 molecular sieve and 1.0g chloropropyltriethoxysilane to 25mL toluene, stir at 60°C for 12h, add 1.0g imidazole, continue stirring for 12h, filter and dry to obtain intermediate A; A and 1.0g of 1,3-propane sultone were placed in 25mL of toluene, refluxed at 70°C for 24h, cooled, filtered, washed with ether, and dried in vacuum at 50°C for 8h to obtain the ionic liquid intermediate B; in 25mL of toluene Add ionic liquid intermediate B and 5mL 37% concentrated hydrochloric acid to the mixture, react at 70°C for 12h, after the reaction is complete, filter to obtain intermediate C; add intermediate C and 0.5g ...

Embodiment 3

[0038] Example 3 Catalytic degradation of microcrystalline cellulose by supported 1-(α-carboxylic acid)methyl-3-methylimidazolium perrhenate ionic liquid

[0039] (1) Supported 1-(α-carboxylic acid)methyl-3-methylimidazolium perrhenate ionic liquid

[0040] The structural formula is as follows:

[0041]

[0042] The preparation method is as follows:

[0043] Add 2.0g MCM-41 molecular sieve and 1.0g chloropropyltriethoxysilane to 25mL toluene, stir at 60°C for 12h, add 1.0g imidazole, continue stirring for 12h, filter and dry to obtain intermediate A; A and 1.0 g of ethyl chloroacetate were placed in 25 mL of toluene, refluxed at 70 ° C for 24 h, cooled, filtered, washed with ether, and dried in vacuum at 50 ° C for 8 h to obtain ionic liquid intermediate B; ionic liquid was added to 25 mL of toluene Intermediate B and 5 mL of 37% concentrated hydrochloric acid were reacted at 70°C for 12 hours. After the reaction was complete, filtered to obtain Intermediate C; Intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com