Heating body structure for rectangle sapphire single crystal

A rectangular and sapphire technology is applied in the field of heating body structures for growing rectangular sapphire single crystals by the bubble growth method. Reasonable temperature gradient in the furnace and the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

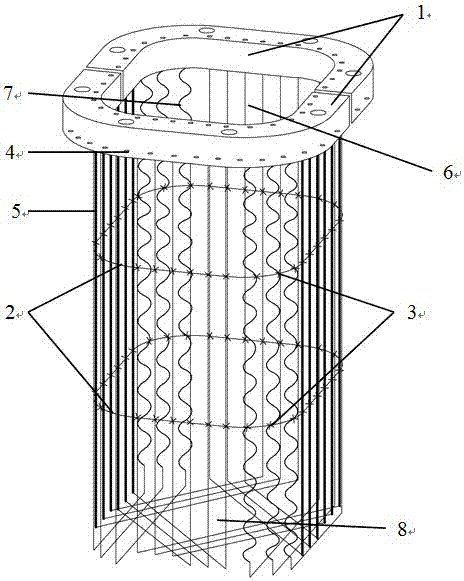

[0017] figure 1 It is a heating body structure for rectangular sapphire single crystal. The structure as a whole consists of a pair of rectangular copper electrode connecting plates 1, longitudinally variable diameter tungsten rods with different diameters, and multiple horizontal tungsten rods. The tungsten rod is composed of the tungsten wire 3 of the longitudinally variable diameter tungsten rod and the molybdenum top wire 4 for fixing the longitudinally variable diameter tungsten rod on the copper electrode connecting plate. Insert the thick end 5 of the variable diameter tungsten rod into the through hole on the long side of the rectangular electrode connecting plate, insert the thin end 6 of the longitudinally variable diameter tungsten rod into the through hole on the short side, and chamfer at the intersection. The tungsten rods at the four corners are bent into a wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com