PI& graphene oxide composite nanofiber film preparation method

A composite technology of nanofiber membrane and graphene, applied in the direction of graphene, chemical instruments and methods, nanocarbon, etc., can solve the problems of small pores and low tensile strength of PI nanofiber membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

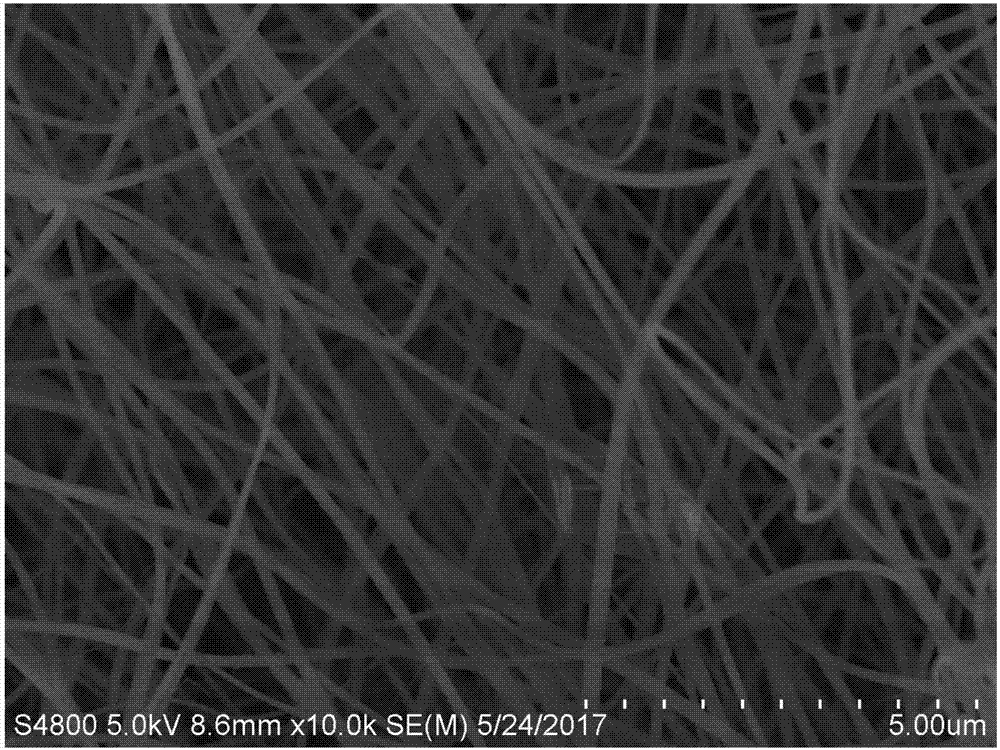

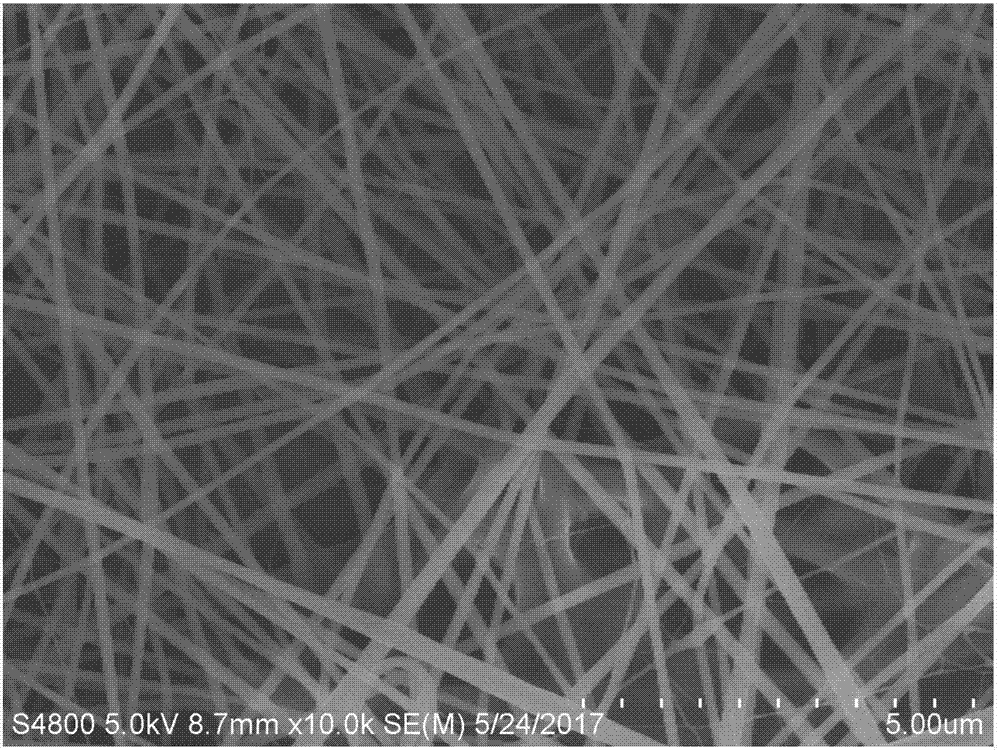

Image

Examples

Embodiment 1

[0023] (1) Preparation of PI spinning solution

[0024] Dissolve 1g of PI in DMF to make a 10ml solution, and adjust the pH of the solution to 6; make 0.2g of sodium lauryl sulfate into a 10ml solution; take 10ml of sodium lauryl sulfate solution and add it dropwise to the PI solution; After the addition, put it in an oil bath at 90°C for 1 hour.

[0025] (2) Preparation of small-sheet graphene oxide

[0026] Add 1g of expandable natural graphite powder with a particle size of 100nm to 100ml of concentrated sulfuric acid, then slowly add 50ml of fuming nitric acid, stir in an ice bath for 24 hours, then pour into 1000ml of deionized water to dilute, filter and wash with water, and store at 50°C Dry for 24 hours, then expand in microwave at 1000w for 1min to obtain expanded graphite; take the above-mentioned expanded graphite and add it to 300ml of concentrated sulfuric acid, then add 4.2g of potassium persulfate and 6g of phosphorus pentoxide, stir at 80°C for 5h, then pour i...

Embodiment 2

[0032] (1) Preparation of PI aqueous solution

[0033] Dissolve 3g of PI in DMF to make a 20ml solution, and adjust the pH of the solution to 6; make 0.6g of sodium lauryl sulfate into a 10ml solution; take 10ml of sodium lauryl sulfate solution and add it dropwise to the PI solution; After the addition is complete, put it in an oil bath and react at 100°C for 0.5h.

[0034] (2) Preparation of small-sheet graphene oxide

[0035] Add 2g of expandable natural graphite powder with a particle size of 200nm to 200ml of concentrated sulfuric acid, then slowly add 75ml of fuming nitric acid, stir in an ice bath for 24 hours, pour into 1500ml of deionized water to dilute, filter and wash with water, and put Dry for 24 hours, then expand in microwave for 2 minutes at 1000w to obtain expanded graphite; take the above-mentioned expanded graphite and add it to 400ml of concentrated sulfuric acid, then add 6g of potassium persulfate and 8g of phosphorus pentoxide, stir at 80°C for 8h, and...

Embodiment 3

[0040] (1) Preparation of PI aqueous solution

[0041] Dissolve 5g of PI in DMF to make a 40ml solution, and adjust the pH of the solution to 6; make 1g of sodium lauryl sulfate into a 20ml solution; take 20ml of sodium lauryl sulfate solution and add it dropwise to the PI solution; add dropwise After completion, put it in an oil bath at 95°C for 1 hour.

[0042] (2) Preparation of small-sheet graphene oxide

[0043] Add 5g of expandable natural graphite powder with a particle size of 300nm to 350ml of concentrated sulfuric acid, then slowly add 100ml of fuming nitric acid, stir in an ice bath for 48 hours, pour into 2000ml of deionized water to dilute, filter and wash with water, and put Dry for 24 hours, then expand in microwave for 5 minutes at 1000w to obtain expanded graphite; take the above-mentioned expanded graphite and add it to 500ml of concentrated sulfuric acid, then add 8g of potassium persulfate and 10g of phosphorus pentoxide, stir at 80°C for 10h, and then pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com