Method for testing the liquid absorption rate of new rare earth power cells

A technology of liquid absorption rate and liquid absorption rate of electric core, which is applied in the direction of using material absorption and weighing, can solve the problems of not reflecting the influence of electric core liquid absorption, large fluctuations in measurement data, and easy cross-contamination, so as to shorten the research and development cycle, High versatility and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for testing the expansion rate of the negative plate of the rare earth new power supply and the liquid absorption of the battery core:

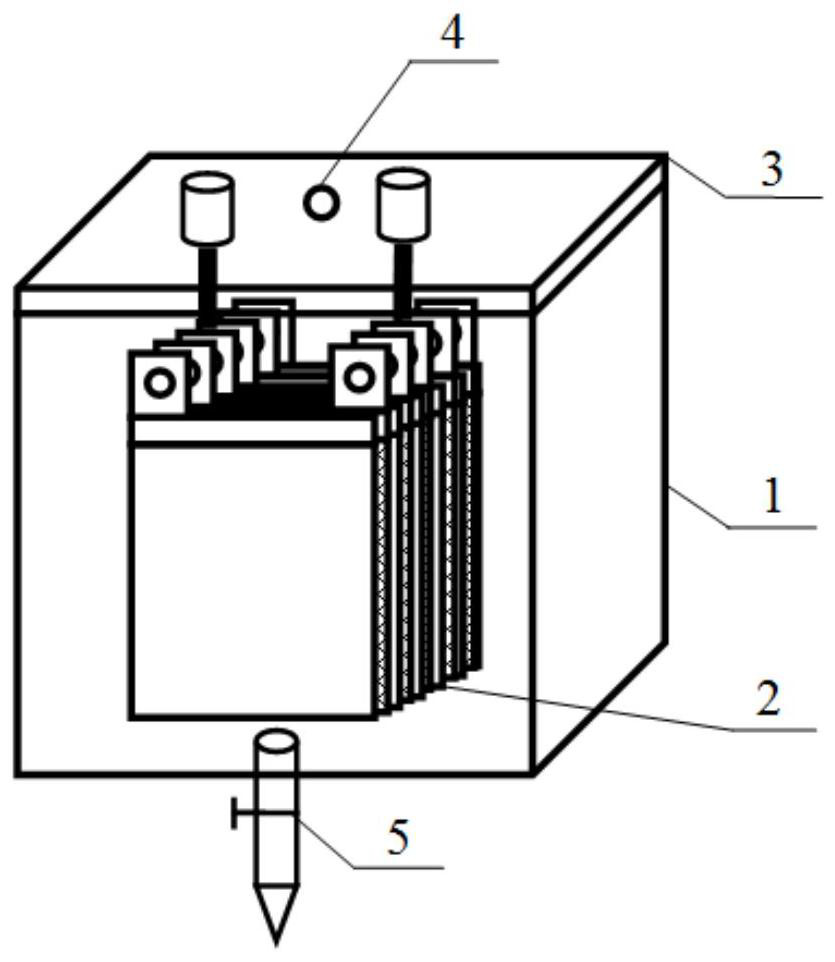

[0048] (1) Measure the volume of the negative electrode sheet, denoted as V 0 , to measure the weight of the rare earth new power supply cell, denoted as M 1 , put it into a transparent square battery case with a rotary valve at the bottom with a complete structure, after the top cover is sealed, add a safety valve and weigh it together, denoted as M 2 ;

[0049] (2) Open the safety valve, seal the seal after injecting liquid at normal pressure, weigh it, and record it as M 3 ; Carry out chemical conversion and activation according to the existing chemical conversion process and weigh, denoted as M 4 ;

[0050] (3) After leaving it aside for 60 hours, open the rotary valve under an inert gas atmosphere of nitrogen at normal pressure, pour out the flowing electrolyte inside, and after 0.8 hours, weigh the battery and record...

Embodiment 2

[0055] A method for testing the expansion rate of the negative plate of the rare earth new power supply and the liquid absorption of the battery core:

[0056] (1) Measure the volume of the negative electrode sheet, denoted as V 0 , to measure the weight of the rare earth new power supply cell, denoted as M 1 , put it into a transparent square battery case with a rotary valve at the bottom with a complete structure, after the top cover is sealed, add a safety valve and weigh it together, denoted as M 2 ;

[0057] (2) Open the safety valve, seal the seal after injecting liquid at normal pressure, weigh it, and record it as M 3 ; Carry out chemical conversion and activation according to the existing chemical conversion process and weigh, denoted as M 4 ;

[0058] (3) After leaving it aside for 48 hours, open the rotary valve under the atmosphere of inert gas and normal pressure argon, pour out the flowing electrolyte inside, and after 0.5 hours, weigh the battery and record ...

Embodiment 3

[0063] A method for testing the expansion rate of the negative plate of the rare earth new power supply and the liquid absorption of the battery core:

[0064] (1) Measure the volume of the negative electrode sheet, denoted as V 0 , to measure the weight of the rare earth new power supply cell, denoted as M 1 , put it into a transparent square battery case with a rotary valve at the bottom with a complete structure, after the top cover is sealed, add a safety valve and weigh it together, denoted as M 2 ;

[0065] (2) Open the safety valve, seal the seal after injecting liquid at normal pressure, weigh it, and record it as M 3 ; Carry out chemical conversion and activation according to the existing chemical conversion process and weigh, denoted as M 4 ;

[0066] (3) After leaving it on hold for 72 hours, open the rotary valve under an inert gas atmosphere of nitrogen at atmospheric pressure, pour out the flowing electrolyte inside, and weigh the battery after 1 hour, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com