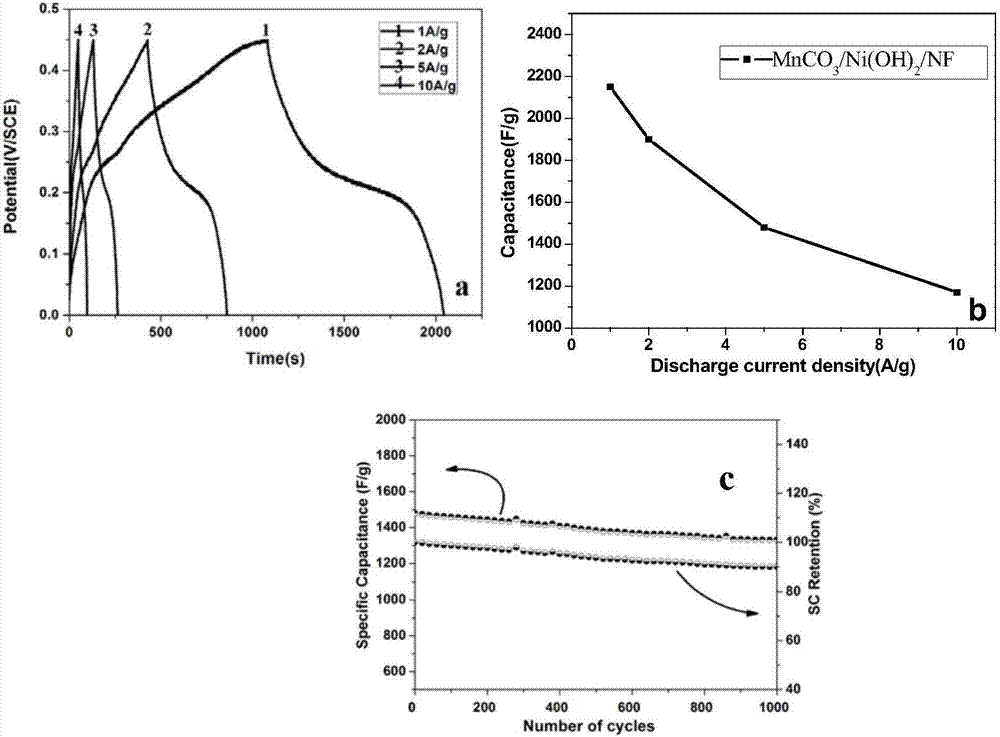

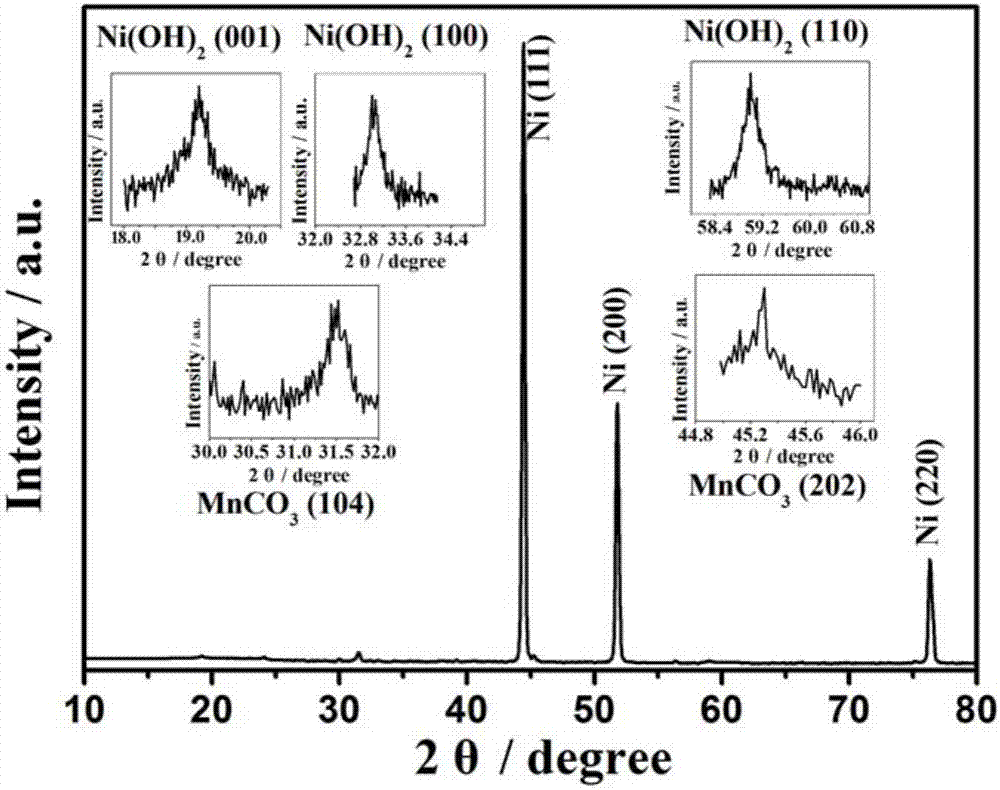

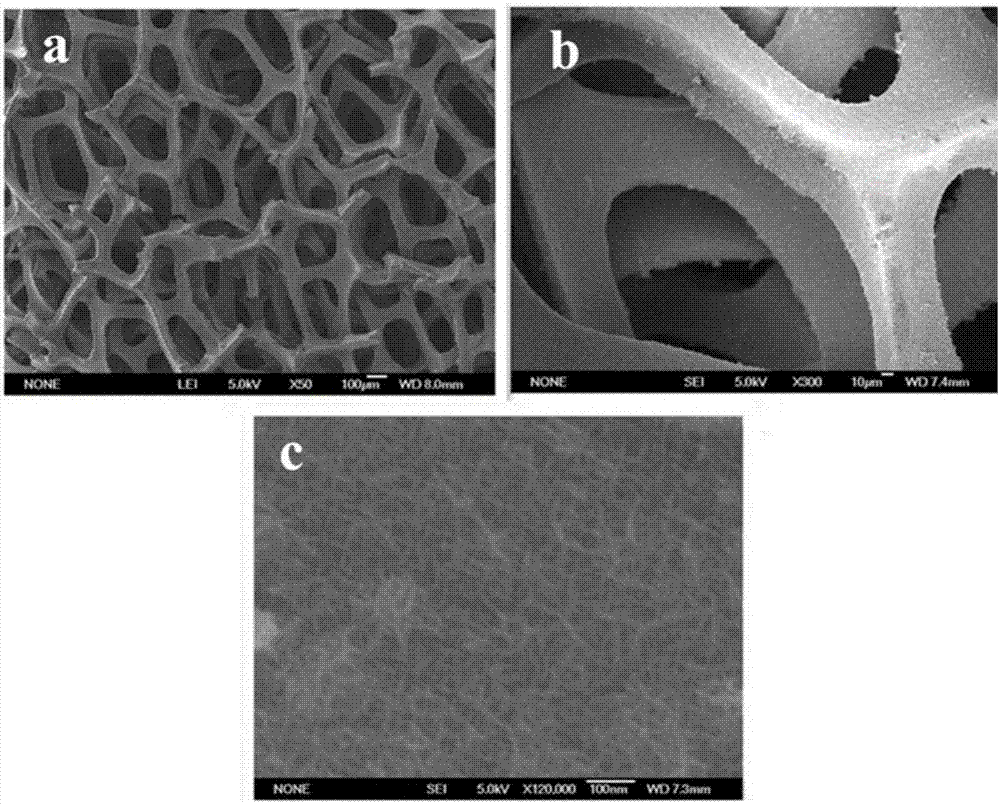

MnCO3/Ni(OH)2/NF multilayer mesh composite electrode material and preparation method thereof

A composite electrode and mesh technology, which is used in the field of preparation of MnCO3/Ni2/NF multi-level mesh composite electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Foamed nickel pretreatment: Cut the foamed nickel substrate into square pieces of 1cm×1cm size, soak the foamed nickel piece in 0.1 mol / L dilute hydrochloric acid for 10min, take out the foamed nickel piece, and wash it with deionized water Afterwards, soak in acetone for 15 min. Finally, take out the nickel foam, wash it three times with deionized water and absolute ethanol ultrasonically, and dry it in a vacuum oven at 60 °C.

[0016] (2) Weigh 0.02g of urea, dissolve it in deionized water, then transfer the urea solution to a stoppered glass test tube, and heat at 90°C for 30min;

[0017] (3) Dip the pretreated nickel foam into 5 mL of 0.5% potassium permanganate solution, and then transfer it to the urea solution obtained in the previous step, and react at 90° C. for 9 h. The foamed nickel sheet was taken out, cleaned with deionized water, and dried in a vacuum oven to obtain MnCO grown on the foamed nickel sheet in situ. 3 / Ni(OH) 2 / NF multi-level network st...

Embodiment 2

[0019] (1) Foamed nickel pretreatment: Cut the foamed nickel substrate into square pieces of 1cm×1cm size, soak the foamed nickel piece in 0.1 mol / L dilute hydrochloric acid for 10min, take out the foamed nickel piece, and wash it with deionized water Afterwards, soak in acetone for 15 min. Finally, take out the nickel foam, wash it three times with deionized water and absolute ethanol ultrasonically, and dry it in a vacuum oven at 60 °C.

[0020] (2) Weigh 0.02g of urea, dissolve it in deionized water, then transfer the urea solution to a stoppered glass test tube, and heat at 85°C for 30min;

[0021] (3) Dip the pretreated nickel foam into 5 mL of 0.5% potassium permanganate solution, and then transfer it to the urea solution obtained in the previous step, and react at 85° C. for 12 hours. The foamed nickel sheet was taken out, cleaned with deionized water, and dried in a vacuum oven to obtain MnCO grown on the foamed nickel sheet in situ. 3 / Ni(OH) 2 / NF multi-level netwo...

Embodiment 3

[0023] (1) Foamed nickel pretreatment: Cut the foamed nickel substrate into square pieces of 1cm×1cm size, soak the foamed nickel piece in 0.1 mol / L dilute hydrochloric acid for 10min, take out the foamed nickel piece, and wash it with deionized water Afterwards, soak in acetone for 15 min. Finally, take out the nickel foam, wash it three times with deionized water and absolute ethanol ultrasonically, and dry it in a vacuum oven at 60 °C.

[0024] (2) Weigh 0.03g of urea, dissolve it in deionized water, then transfer the urea solution to a stoppered glass test tube, and heat at 90°C for 15min;

[0025] (3) Dip the pretreated nickel foam into 7.5mL 0.5% potassium permanganate solution, and then transfer it to the urea solution obtained in the previous step, and react at 90°C for 6h. The foamed nickel sheet was taken out, cleaned with deionized water, and dried in a vacuum oven to obtain MnCO grown on the foamed nickel sheet in situ. 3 / Ni(OH) 2 / NF multi-level network structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com