A process and device for treating byproduct mixed waste salts during phenol production

A technology of production process and treatment process, which is applied in the direction of sulfate/bisulfate preparation, alkali metal sulfite/sulfate purification, etc., can solve the problem of unsatisfactory disposal of phenol mixed waste salt, and reduce the oxidation time , reduce the effect of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

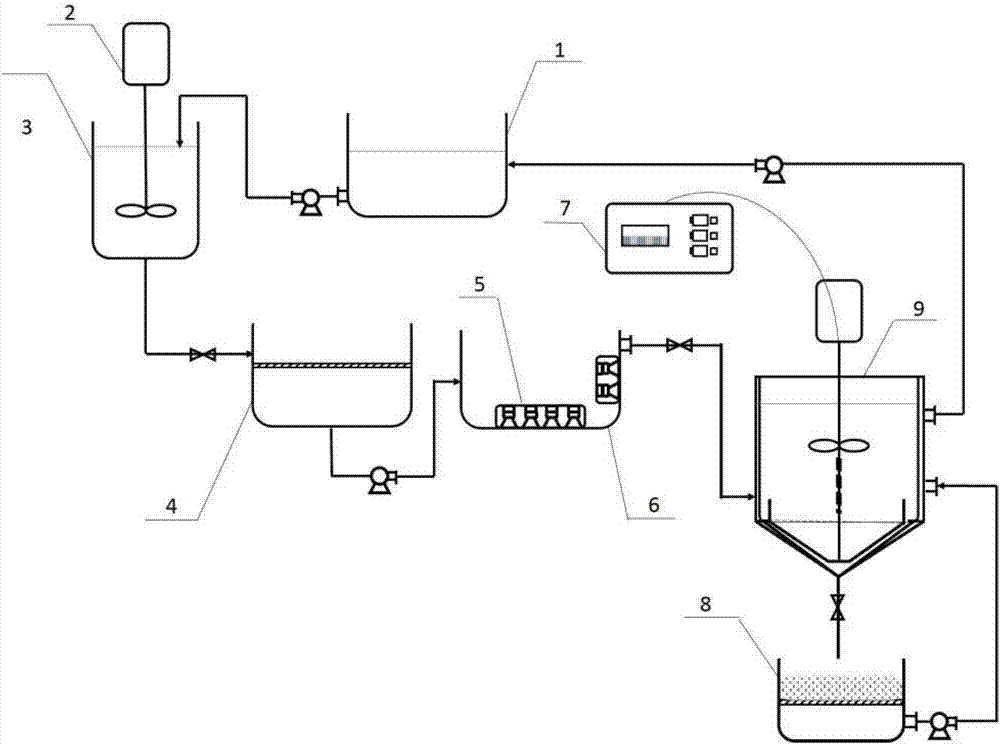

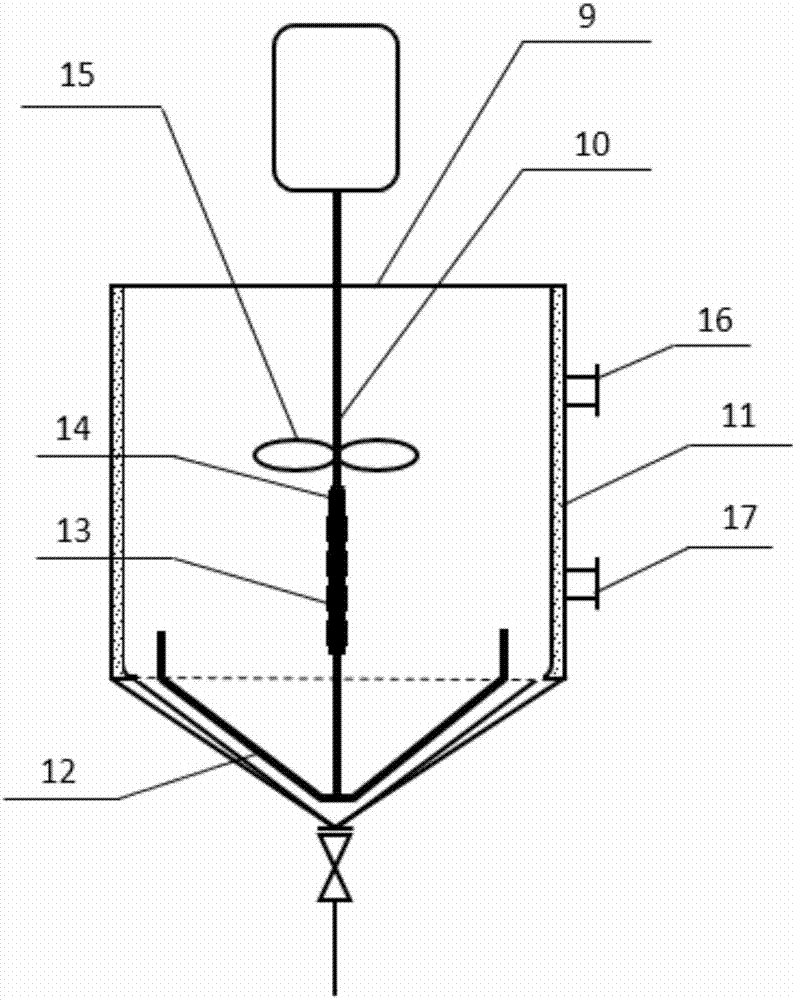

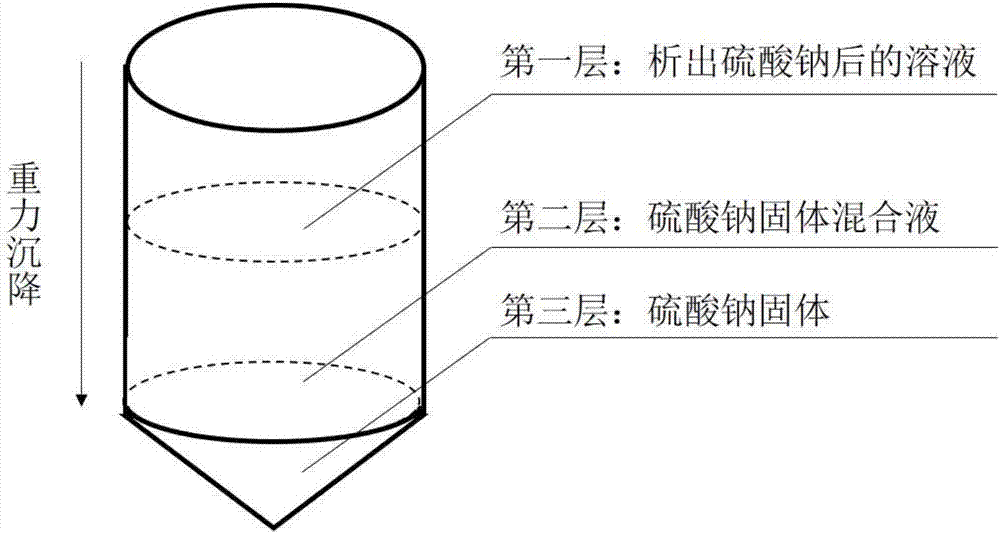

[0057] Such as figure 1 As shown, the device includes an adsorption pretreatment unit, an ultrasonic oxidation treatment unit, and an ultrasonic crystallization unit, wherein the adsorption pretreatment unit includes a dissolution tank 1, an adsorption reactor 3, and a filter tank 4, and the ultrasonic oxidation treatment unit includes an ultrasonic oxidation reactor 6. The crystallization unit includes an ultrasonic crystallizer 9 and a crystallizer 8, the dissolution tank 1, the adsorption reactor 3, the filter 4, the ultrasonic oxidation reactor 6 and the ultrasonic crystallizer 9 are connected in sequence through pipelines, and the crystallizer 8 is located in the ultrasonic crystallizer. Below the salt outlet at the bottom of the device 9, the outlet pipe 19 on the crystallizer 8 is connected to the solution inlet 17 on the housing of the ultrasonic crystallizer 9, and the solution outlet A16 on the housing of the ultrasonic crystallizer 9 is connected to the dissolution t...

Embodiment 2

[0063] Under normal temperature conditions, 12kg of by-product mixed salt (solid mixed sulfate) in the phenol production process was added in the dissolution tank 1, and then 50L of water was added to the dissolution tank 1, stirred and dissolved, and the color of the solution was light yellow.

[0064] Use a pump to transport the light yellow solution to the adsorption reactor 3, and a stirrer 2 is installed on the upper part of the adsorption reactor 3, and the stirring paddle of the stirrer extends into the solution of the adsorption reactor 3 for stirring. Regulate the pH value with sulfuric acid in the adsorption reactor 3 to be 5, add gac, the dosage of described gac is 0.1% of the solution quality in the adsorption reactor 3, after stirring for 20min, remove the part organic matter in the mixed salt, and to The solution undergoes decolorization, and then the solution enters filter 4.

[0065] The filter 4 is divided into upper and lower layers, with a partition in the m...

Embodiment 3

[0070] Under normal temperature conditions, 18kg solid mixed sulfate is added in dissolving tank 1, then adds 50L water in dissolving tank 1, stirs and dissolves, and the solution color is light yellow.

[0071] Use a pump to transport the light yellow solution to the adsorption reactor 3, and a stirrer 2 is installed on the upper part of the adsorption reactor 3, and the stirring paddle of the stirrer extends into the solution of the adsorption reactor 3 for stirring. In the adsorption reactor 3, adjust the pH value to 5 with sulfuric acid, add activated carbon, the dosage of the activated carbon is 0.3% of the solution mass, and after stirring for 20 minutes, the solution enters the filter tank 4.

[0072] The filter 4 is divided into upper and lower layers, with a partition in the middle, and the partition has circular holes with a porosity of 75%. The filter cloth is covered above the partition, the solution enters through the upper part of the filter, and the activated car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com