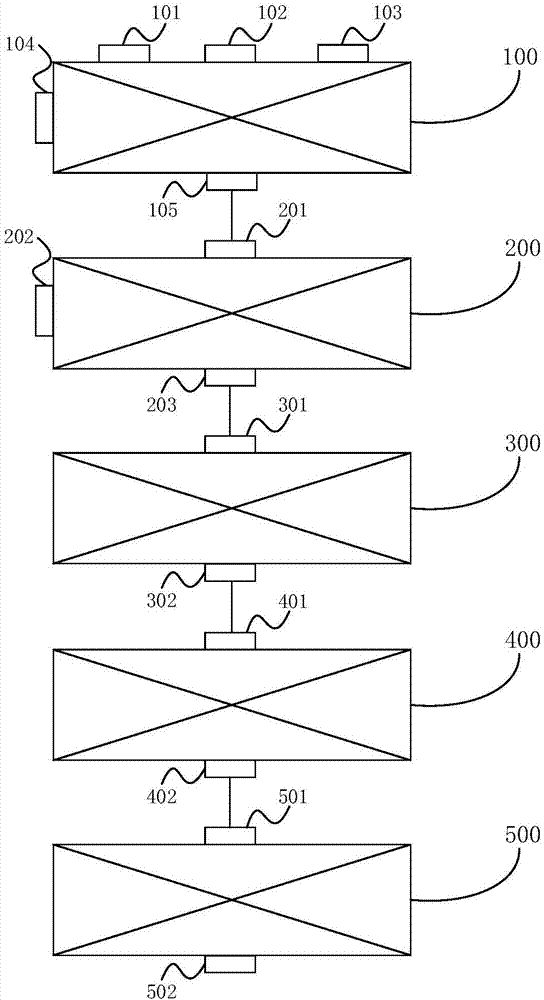

Lithium hydroxide monohydrate preparation system

A technology of monohydrate lithium hydroxide and lithium hydroxide, applied in the direction of lithium oxide;/hydroxide, can solve the problems of low lithium yield and lithium loss, and achieve stable industrial process, high yield and product quality. Stable and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

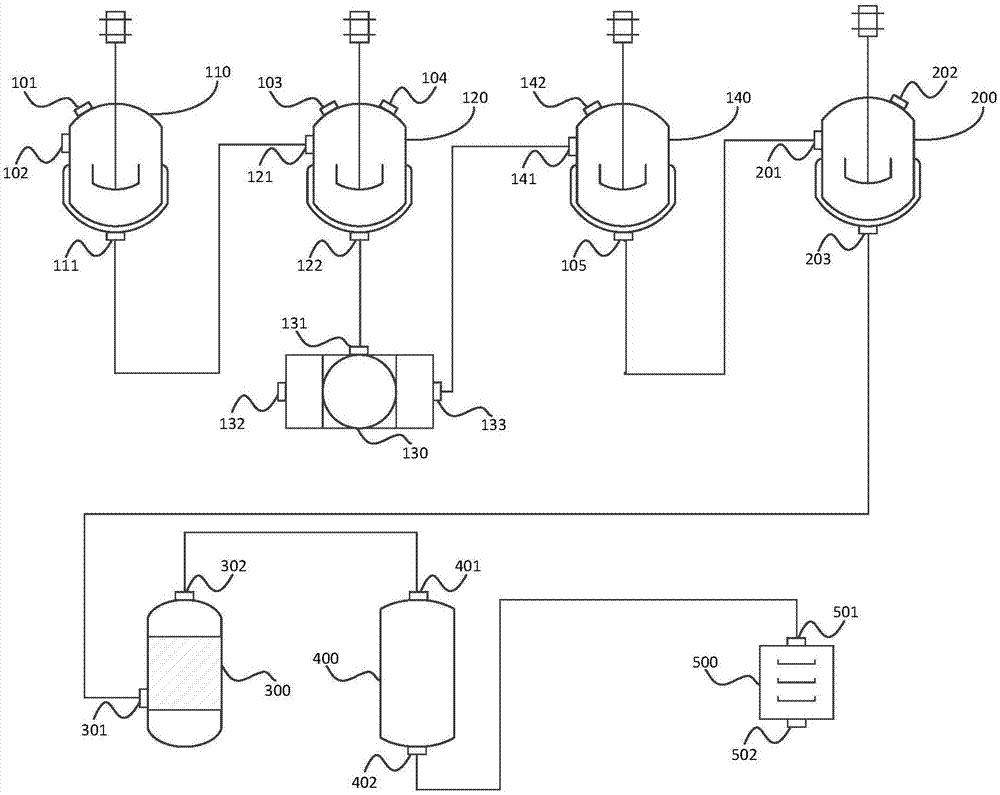

Embodiment 1

[0055] Adopt carbonization impurity removal device, add 200g industrial pure lithium carbonate (main content 97wt%) into 2L pure water, stir, pass into carbon dioxide gas, until lithium carbonate dissolves completely, stop ventilating. Add 0.2g of EDTA to it, stir to dissolve, and filter to obtain clear liquid. Then the clear liquid was heated to 90° C., and stirred while heating, a white solid was seen to be precipitated, and filtered to obtain refined lithium carbonate with a main content of 99 wt%. The prepared refined lithium carbonate and freshly prepared calcium hydroxide are supplied to the causticization device for causticization reaction, the reaction temperature is 95°C, the reaction time is 1h, and after the reaction, the lithium hydroxide solution is obtained by filtration. The lithium hydroxide solution is supplied to the ion exchange device, and passed through the reaction tower loaded with large-pore cation exchange resin D401 to obtain a refined lithium hydroxi...

Embodiment 2

[0057] Adopt carbonization impurity removal device, join 200g industrial pure lithium carbonate (main content 97wt%) into 4.4L pure water, stir, pass into carbon dioxide gas, until lithium carbonate dissolves completely, stop ventilating. Add 0.3g of EDTA to it, stir to dissolve, and filter to obtain clear liquid. Then the clear liquid was heated to 85° C., and stirred while heating, a white solid was seen to be precipitated, and filtered to obtain refined lithium carbonate with a main content of 99 wt%. The prepared refined lithium carbonate and freshly prepared calcium hydroxide are supplied to the causticizing device for causticizing reaction, the reaction temperature is 95°C, and the reaction time is 0.5h. After the reaction, the lithium hydroxide solution is obtained by filtration. The lithium hydroxide solution is supplied to the ion exchange device, and passed through the reaction tower loaded with large-pore cation exchange resin D401 to obtain a refined lithium hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com