Preparation method for high-strength light-operated quick self-repairing hydrogel

A self-healing and hydrogel technology, applied in the direction of additive processing, can solve the problems of low mechanical strength of hydrogel, low strength of self-healing material, single repair medium, etc., and achieve good social and ecological benefits, and it is effective. , the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of a high-intensity light-controlled rapid self-healing hydrogel with a graphene oxide content of 1wt.%:

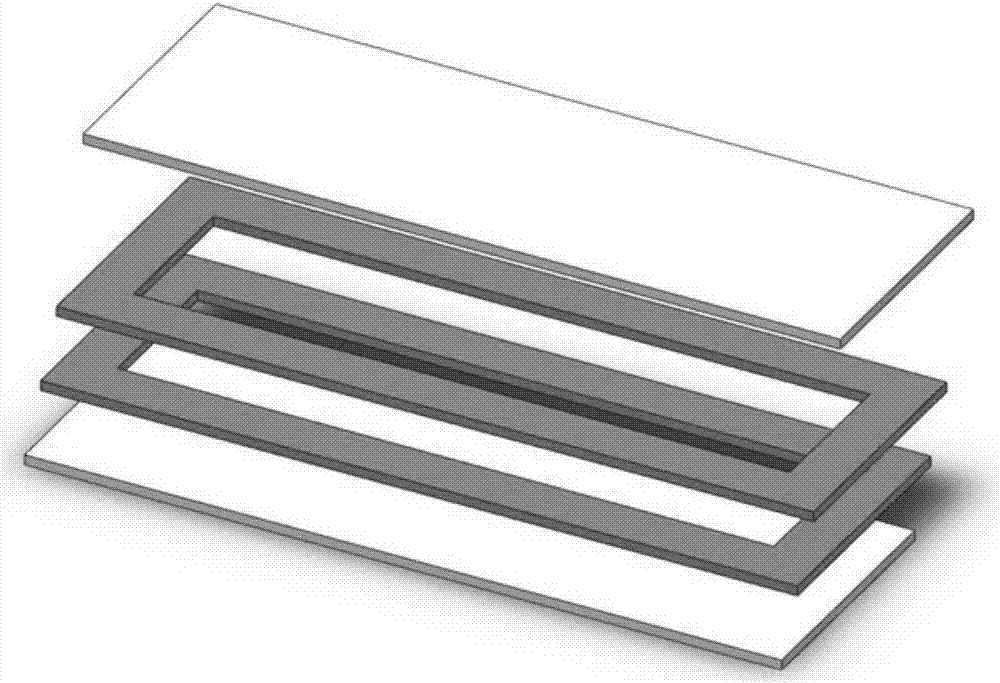

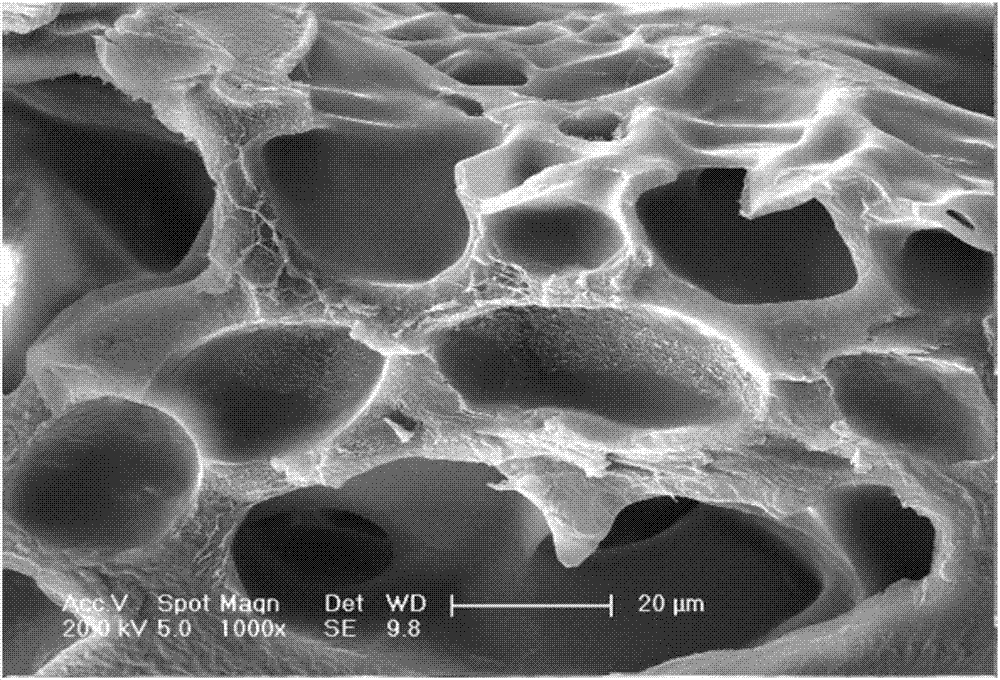

[0024] Using N,N-dimethylacrylamide as monomer, XLS-type synthetic lithium magnesium silicate as crosslinking agent, potassium persulfate as initiator, N,N,N',N'-tetramethylethylenediamine as Catalyst, 2wt.% nano wood pulp cellulose as reinforcement phase. Add 1wt.% graphene oxide into distilled water under ice-water bath conditions, ultrasonically oscillate for half an hour and then stir for half an hour; then add nano-wood pulp cellulose and stir for half an hour; then add a crosslinking agent and stir for 1 hour; then add mono The body was stirred for 2 hours; finally, the initiator and catalyst were added in turn, and stirred for 5 minutes. The resulting solution is poured into the corresponding mould, see figure 1 . The reaction time is 24 hours at 25°C. The obtained sample microstructure presents a honeycomb-like structure, such as ...

Embodiment 2

[0025] Example 2: Preparation of high-intensity light-controlled fast self-healing hydrogels with graphene oxide content of 2wt.% and 3wt.%:

[0026] Using N,N-dimethylacrylamide as monomer, XLS-type synthetic lithium magnesium silicate as crosslinking agent, potassium persulfate as initiator, N,N,N',N'-tetramethylethylenediamine as Catalyst, 2wt.% nano wood pulp cellulose as reinforcement phase. Add 2wt.% graphene oxide into distilled water under ice-water bath conditions, ultrasonically oscillate for half an hour and then stir for half an hour; then add nano-wood pulp cellulose and stir for half an hour; then add a crosslinking agent and stir for 1 hour; then add mono The body was stirred for 2 hours; finally, the initiator and catalyst were added in turn, and stirred for 5 minutes. The resulting solution was poured into the corresponding moulds. The reaction time is 24 hours at 25°C. A 3wt.% high-intensity light-controlled fast self-healing hydrogel was prepared by the s...

Embodiment 3

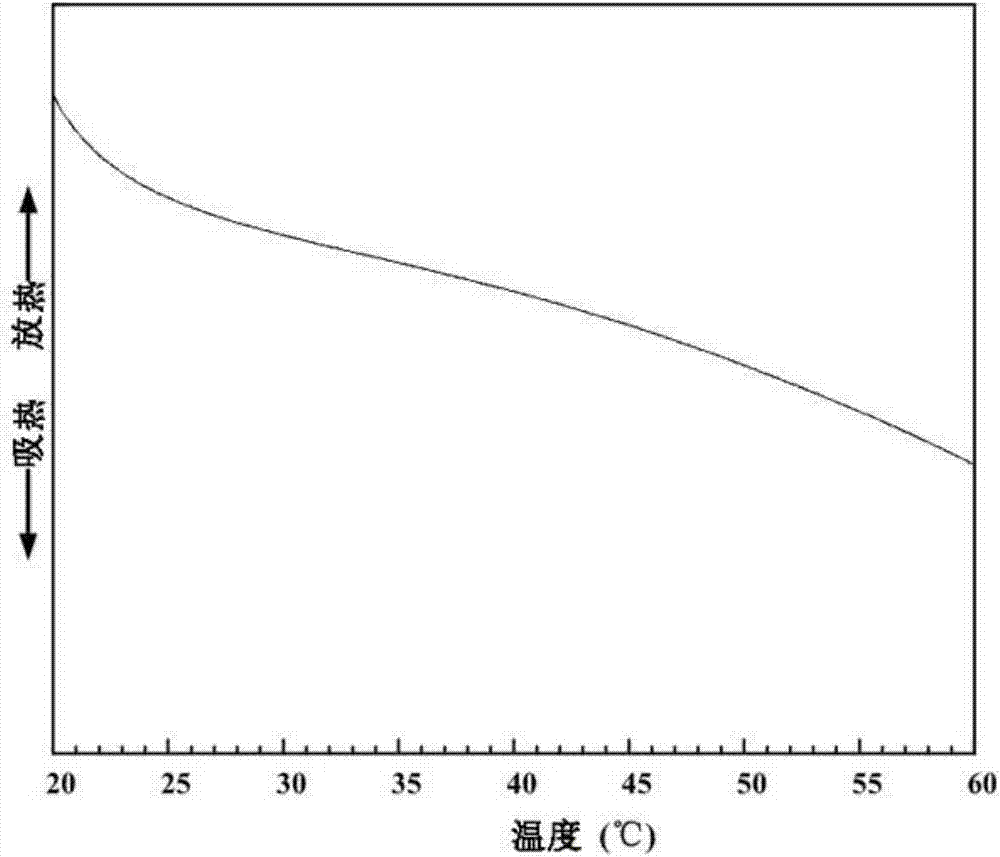

[0027] Example 3: Carry out repair rate experiment on high-intensity light-controlled fast self-healing hydrogel:

[0028] The prepared high-intensity light-controlled rapid self-healing hydrogel with 1wt%-3wt.% graphene oxide content was subjected to self-healing experiments. The experimental process is to put together the fracture parts of the cut tensile samples and irradiate them sequentially under near-infrared light for 1 to 5 minutes. The sample under the corresponding irradiation time is subjected to a tensile test, and the repair rate value is obtained by dividing the corresponding stress value with the stress value in Example 2, such as Figure 4 shown. It can be seen from the repair rate value that as the graphene oxide content increases, the self-healing rate gradually increases, and as the repair time increases, the self-healing hydrogel with a graphene oxide content of 3wt.% reaches 92% repair in 5 minutes Rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com