Environment-friendly enzyme starter and preparation method thereof

An environmentally friendly enzyme and starter technology, applied in the direction of fungi, bacteria, etc., can solve single problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

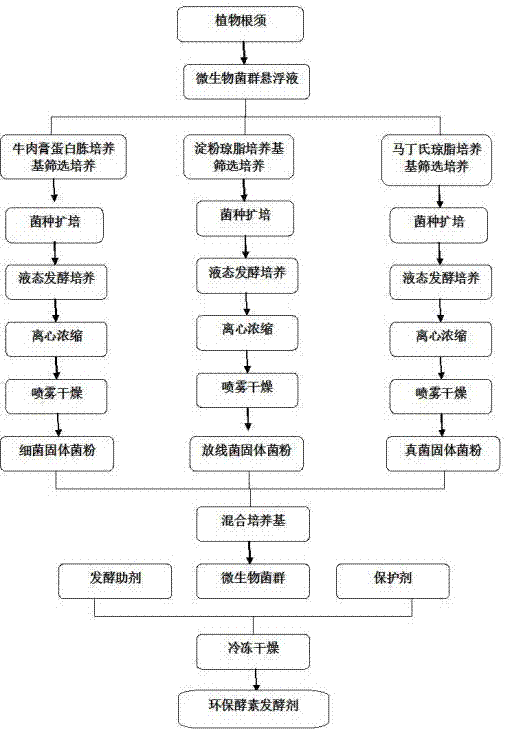

Image

Examples

Embodiment 1

[0027]Weigh 50g of plant roots, add it to a triangular flask containing 200mL of sterile water, shake for 5 minutes, so that the flora is evenly dispersed in the sterile water, which is the microbial flora suspension, and take 0.5mL of microbial flora respectively. The suspension was inoculated into beef extract peptone solid plate medium, starch agar solid plate medium and Martin's agar plate medium, and cultivated in a 28°C incubator until colonies grew. The microorganisms were expanded by using the corresponding liquid medium, inoculated into the fruit peel and vegetable mixture for liquid fermentation, fermented under aerobic conditions for 3 days and then centrifuged and concentrated, and spray-dried to obtain three kinds of solid bacteria powders after adding resistant starch; According to the formula ratio, 50 parts of solid bacterial powder, 20 parts of solid fungus powder, and 5 parts of solid bacteria powder of actinomycetes were added to the mixed medium after being ...

Embodiment 2

[0035] Weigh 100g of plant roots, add it to a triangular flask containing 400mL of sterile water, shake for 8 minutes, so that the flora is evenly dispersed in the sterile water, that is, the microbial flora suspension, take 1mL of microbial flora suspension The liquid was inoculated into beef extract peptone solid plate medium, starch agar solid plate medium and Martin's agar plate medium, and cultivated in a 30°C incubator until colonies grew, and picked Microorganisms, using the corresponding liquid medium to carry out bacterial culture expansion, inoculated into the fruit peel and vegetable mixture for liquid fermentation, fermented for 4 days under aerobic conditions, centrifuged and concentrated, and spray-dried after adding resistant starch to obtain three kinds of solid bacteria powder; In the formula ratio, 60 parts of solid bacterial powder, 15 parts of solid fungus powder, and 10 parts of solid bacteria powder of actinomycetes were added to the mixed medium after bei...

Embodiment 3

[0043] Weigh 100g of plant roots, add it to a triangular flask containing 400mL of sterile water, shake for 10 minutes, so that the flora is evenly dispersed in the sterile water, that is, the microbial flora suspension, take 1mL of microbial flora suspension The liquid was inoculated into beef extract peptone solid plate medium, starch agar solid plate medium and Martin's agar plate medium, and cultivated in a 30°C incubator until colonies grew, and picked Microorganisms, using the corresponding liquid medium to carry out bacterial culture expansion, inoculated into the fruit peel and vegetable mixture for liquid fermentation, fermented for 5 days under aerobic conditions, centrifuged and concentrated, and spray-dried after adding resistant starch to obtain three kinds of solid bacteria powder; In the formula ratio, 70 parts of solid bacterial powder, 10 parts of solid fungus powder, and 15 parts of solid bacteria powder of actinomycetes were added to the mixed medium after be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com