Method for preparing carbon nanofiber aerogel

A carbon nanofiber, aerogel technology, applied in the field of nanomaterials, can solve problems such as unsuitability for commercialization, difficulty in large-scale production, and difficulty in aerogels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing carbon nanofiber airgel, comprising the following steps:

[0033] heat-treating the β-lactoglobulin solution at a pH value of 1 to 3 to obtain a β-lactoglobulin amyloid fiber solution;

[0034] mixing the β-lactoglobulin amyloid fiber solution with sugar and reacting to obtain a carbon nanofiber hydrogel;

[0035] The carbon nanofiber hydrogel is dried to obtain the carbon nanofiber aerogel.

[0036] The structure of the airgel prepared by the preparation method provided by the invention is controllable, and the adsorption property is good; the method is simple and easy, has good repeatability, and the raw materials are proteins and carbohydrates widely existing, and is easy to realize large-scale preparation.

[0037] In the invention, the beta-lactoglobulin solution is heat-treated under the condition that the pH value is 1-3 to obtain the beta-lactoglobulin amyloid fiber solution.

[0038] In the present invention, the ...

Embodiment 1

[0054] Dissolve 10g of protein powder in 90mL of water, stir evenly, adjust it to pH=2 with 1mol / L hydrochloric acid, at this time a large amount of precipitation appears in the solution, centrifuge the adjusted solution in a centrifuge at 14000rpm for 16min, and remove the upper layer After the supernatant was collected, it was suction filtered to obtain a purified protein solution.

[0055] The pH value of the obtained purified protein solution is adjusted to 2 and then loaded into a dialysis band of 6000 to 8000 g / mol. The dialysis band is placed in water with a pH value of 2 (the solution volume in the dialysis band: the volume of water=1 :40) dialysis for 6 hours, and then put the dialysis belt into deionized water (pH=7) for dialysis for 6 hours (volume ratio is 1:40), and the solution in the dialysis belt is collected to obtain β-lactoglobulin solution , see figure 1 , figure 1 It is a digital photograph of the β-lactoglobulin solution prepared in Example 1 of the pre...

Embodiment 2

[0061] Dissolve 10g of protein powder in 90mL of water, stir evenly, adjust it to pH = 2 with 1mol / L hydrochloric acid, at this time a large amount of precipitation appears in the solution, centrifuge the adjusted solution in a centrifuge at 14000rpm for 16min, and The supernatant was collected and filtered with suction to obtain a purified protein solution.

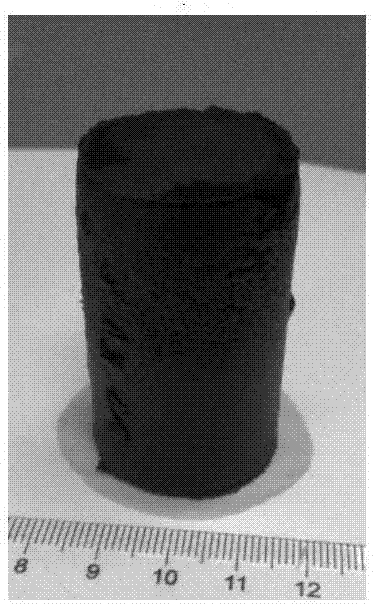

[0062] The pH value of the obtained purified protein solution is adjusted to 2 and then loaded into a dialysis band of 6000 to 8000 g / mol. The dialysis band is placed in water with a pH value of 2 (the solution volume in the dialysis band: the volume of water=1 :40) for 6 hours of dialysis, and then put the dialysis belt into deionized water (pH=7) for 6 hours of dialysis (volume ratio: 1:40). Collect the solution in the dialysis zone to obtain a β-lactoglobulin solution; adjust the concentration of the obtained β-lactoglobulin solution to 4wt%, and after the pH value is 2, take 100mL and put it into a sealed reagent bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com