Preparation method of tetramer nickel substituted silicon tungsten oxygen cluster catalyst

A technology of catalyst and silicon tungsten, which is applied in the field of preparation of tetrapolynickel instead of silicon tungsten oxygen cluster catalyst, can solve the problems of catalytic activity to be improved, achieve good catalytic activity, simple preparation method, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

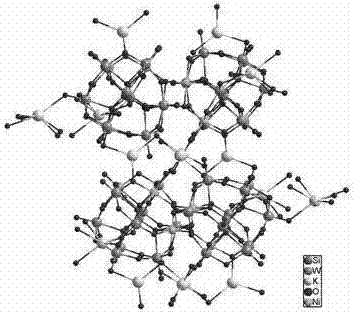

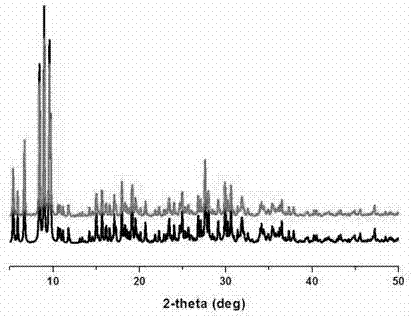

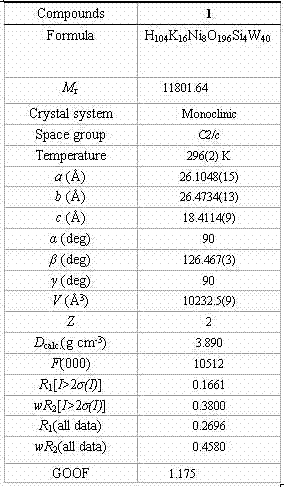

[0027] Example 1 Compound K 16 (H 2 O) 44 Ni 8 (H 2 O) 8 Si 4 W 40 o 144 The preparation, its synthetic steps are as follows:

[0028] Add K successively to a clean beaker 8 [γ-SiW 10 o 36 ]·12H 2 O (2mmol) and 50mL water, stir at 60°C for 15min, add nickel chloride (1mmol), adjust the pH value between 5 with dilute acetic acid, react for 10h, after the reaction is completed, cool to room temperature, filter, and the filtrate is at room temperature Evaporated slowly under the condition of 3~4 days to obtain bulk single crystal. The yield is about 30%.

Embodiment 2

[0029] Example 2 Compound K 16 (H 2 O) 44 Ni 8 (H 2 O) 8 Si 4 W 40 o 144 The preparation, its synthetic steps are as follows:

[0030] Add K successively to a clean beaker 8 [γ-SiW 10 o 36 ]·12H 2 O (3mmol) and 60mL water, stir at 60°C for 15min, add nickel chloride (1mmol), adjust the pH value between 5 with dilute acetic acid, react for 10h, after the reaction is completed, cool to room temperature, filter, and the filtrate is at room temperature Evaporate slowly under the condition of 3~4 days to obtain bulk single crystal. The yield is about 35%.

Embodiment 3

[0031] Example 3 Compound K 16 (H 2 O) 44 Ni 8 (H 2 O) 8 Si 4 W 40 o 144 The preparation, its synthetic steps are as follows:

[0032]Add K successively to a clean beaker 8 [γ-SiW 10 o 36 ]·12H 2 O (3mmol) and 70mL water, stirred at 60°C for 15min, added nickel salt (2mmol), adjusted the pH value between 6 with dilute acetic acid, reacted for 15h, after the reaction was completed, cooled to room temperature, filtered, and the filtrate was kept at room temperature Evaporate slowly, and block single crystals are obtained after 3-4 days. The yield is about 42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com